Packaging is everywhere. Most packaging consumes considerable resources and energy during production and transportation. Even to produce one ton of cardboard packaging, which many consumers see as "greener", requires at least 17 trees, 300 liters of oil, 26,500 liters of water and 46,000 kilowatts of energy. These consumable packages usually have a very short useful life, and most of the time they enter the natural environment due to improper disposal and become the cause of various environmental problems.

The most immediate solution to packaging pollution is to promote sustainable packaging, which is the development and use of packaging that is recyclable, reusable and made from rapidly renewable resources or materials. As consumer groups become more aware of ecological protection, improving packaging to reduce the ecological footprint of products has become one of the social responsibilities that companies must assume.

What is sustainable packaging?

Sustainable packaging is more than just using eco-friendly boxes and recycling; it covers the entire lifecycle of packaging from front-end sourcing to back-end disposal. The sustainable packaging manufacturing standards outlined by the Sustainable Packaging Coalition include

- Beneficial, safe, and healthy for individuals and communities throughout the life cycle

- Meet market requirements for cost and performance

- Use renewable energy for sourcing, manufacturing, transportation and recycling

- Optimize the use of renewable materials

- Manufactured using clean production technologies

- Optimize materials and energy by design

- Recoverable, reusable and recyclable

A recent survey by international consulting firm Accenture shows that more than half of consumers are willing to pay a premium for sustainable packaging. This article presents five innovative sustainable packaging designs. Some of these examples have already gained acceptance in the consumer market, and they show that sustainable packaging does not have to be a burden, and that it has the potential to sell well and expand brand reach while ensuring that normal consumer needs are met.

Packing computers with plants

Most of the outer packaging of electronic products is made of polystyrene (or resin), which is not biodegradable and can rarely be recycled. To solve this problem, many companies are actively exploring innovative research and development of biodegradable plant-based packaging materials.

In the electronics industry, Dell, for example, has introduced bamboo-based packaging and mushroom-based packaging in the personal computer industry in recent years to promote the widespread use of innovative materials that are biodegradable. Among other things, bamboo is a tough, easily renewable plant that can be converted into fertilizer, making it an excellent packaging material to replace pulp, foam and crepe paper commonly used in packaging. More than 70 percent of Dell's laptop packaging is made from bamboo brought in from Chinese bamboo forests that meet Forest Stewardship Council (FSC) regulations.

Compared to bamboo-based packaging, which is more suitable for lighter products such as laptops and smartphones, mushroom-based packaging is more suitable as a cushion for heavier products such as servers and desktops. The mushroom-based cushion developed by Dell is a mycelium formed by putting common agricultural wastes such as cotton, rice, and wheat bark into a mold and filling it with mushroom strains for a growth cycle of 5 to 10 days. This production process not only reduces the use of traditional materials based on the enhanced protection of packaging for electronics, but also facilitates the faster degradation of packaging into fertilizer after use.

Replaced by glue six bottles of plastic rings

Six bottle plastic ring is a set of plastic rings with six round holes, can be connected to six bottles of beverage cans, used more in Europe and the United States. This plastic ring not only involves the problem of pollution from production emissions, but its special shape also makes it very easy to get stuck in the bodies of animals after flowing into the sea. In the 1980s, one million seabirds and 100,000 marine mammals died each year in the world from these six-bottle plastic rings.

Over the years since the dangers of this plastic packaging were raised, various prominent beverage companies have been trying to find ways to make the plastic rings easier to break down. However, decomposing plastic is still plastic, and a decomposable plastic ring is hardly a solution to the pollution problem of its plastic material itself. So in 2019, Danish beer company Carlsberg introduced a new design, the "Snap Pack": it took the company three years and 4,000 iterations to create an adhesive that is strong enough to hold six cans together in place of the traditional plastic ring, and whose composition does not prevent cans from being recycled later.

Although the Snap Pack still requires a thin plastic strip in the middle of the beer can to "carry", the design still has a good environmental effect. Carlsberg estimates that Snap Pack can reduce the use of plastic packaging by more than 1,200 tons per year, which not only helps to reduce plastic waste, but also effectively reduces Carlsberg's own production carbon emission values.

Making liquid soap bottles out of marine plastic

As we have mentioned in previous articles, 85% of the world's beach litter is plastic waste. Unless the world changes the way plastics are produced, used and disposed of soon, the amount of plastic waste entering aquatic ecosystems could reach 23 to 37 million tons per year in 2024. With waste plastic piling up in the ocean on one side and new plastic packaging that needs to be produced constantly on the other, why not try making packaging from ocean waste? With this in mind, in 2011, Method, an American detergent brand, created the world's first liquid soap bottle made from marine plastic waste.

The plastic liquid soap bottle comes from a Hawaiian beach, where the brand's employees spent more than a year personally participating in the process of collecting plastic waste on Hawaiian beaches and then working with recycling partner Envision Plastics to develop a plastic recycling process to design marine PCR plastic of the same quality as virgin HDPE for use in retail packaging for new products.

The vast majority of liquid soap bottles in the U.S. today contain varying degrees of recycled plastic, 25% of which comes from the ocean circulation. The brand's founders say that making plastic packaging from ocean plastic may not necessarily be the ultimate solution to the ocean plastic problem, but they believe it's a thought in the right direction that there is a way to reuse the plastic that already exists on the planet.

Buy something but return the package

The carbon footprint and waste associated with cardboard shoe boxes and large amounts of liner paper are key entry points for many footwear brands to meet their sustainability goals. For example, Vans uses 80% recycled paper and soy-based inks for some of its shoeboxes; Allbirds has enhanced its shoebox design to be more resistant to shipping in order to reduce double packaging, etc.

In 2011, German sports brand PUMA collaborated with designers to launch a creative shoebox: the Clever Little Bag. The internal cardboard box of this shoe box is made of 100% recycled paper, compared to traditional shoe boxes can save more than 65% of paper and 60% of water, energy and fuel consumption each year; the top lid of the shoe box is also a tote bag made of recyclable plastic, which not only can avoid the extra supply of handbags in the mall, the shoes out, the bag itself can also be used as a fashion shopping bag repeatedly, ideally, these shoe box bags can save 275 tons of plastic bags.

After its launch, the shoebox received several design awards, including the IDEA Award and the German iF Award. It stands out not only because of the integration of the product with sustainability, but also because it achieves a balance between sustainability and fashion aesthetics, when sustainability becomes synonymous with "trendy".

Automatic beverage vending machine without bottles

According to Euromonitor International, more than 481 billion plastic bottles are now wasted globally each year, which equates to more than 1.3 billion bottles being thrown away every day, of which less than one tenth are effectively recycled on average. Bottled beverages are one of the main sources of plastic bottle waste, so many companies involved in bottled products are trying to take steps to reduce their impact.

It's hard to talk about bottled beverages without mentioning Coca-Cola, one of the world's largest beverage companies. To advance its BYOB program (Bring your own bottle) to reduce packaging waste, Coca-Cola is launching a packaging innovation in 2019: the DASANI PureFill automatic beverage vending machine. The vending machine itself is also a free water dispenser, consumers only need to bring their own bottles, pay a small fee through the mobile app, you can choose different flavors of carbonated beverages. So far, more than 100 units of this vending machine have been placed one after another, and the main application scenarios are campuses, hospitals, companies, theme parks, etc., because people in these scenarios are more likely to carry both a cell phone and a reusable water bottle with them.

It is worth mentioning that Coca-Cola also made some other interesting attempts to develop user habits during the pilot. For example, to encourage participation, Coca-Cola will first sell creative water bottles to students and staff at pilot schools, and consumers will be able to "drink back" the cost of the bottles by using them for 10 weeks without interruption. Then, for example, Coca-Cola introduced the classic Freestyle self-serve beverage machine in some schools, which allows consumers to mix their own flavors that are not available in stores, leaving curious young audiences to bring their own cups when disposable plastic containers are not provided.

Cosmetics that can be restocked directly

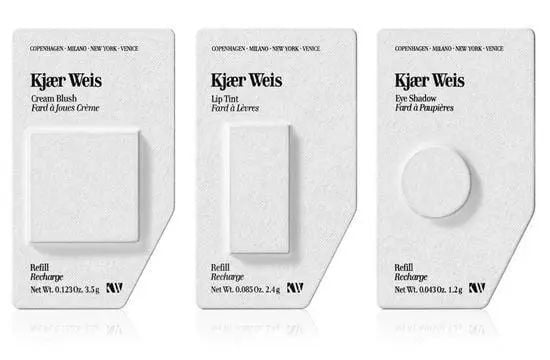

Consumers who habitually use the same brand of cosmetics can easily save up a large pile of identical plastic packaging, and since cosmetic containers are generally not large in size, consumers can't think of a good way to use them even if they have a desire to use them twice. "Since cosmetic packaging is for cosmetics, it's better to let it stay filled." Kjaer Weis, an American organic cosmetics brand, then offered a sustainable packaging solution: refillable boxes.

These refillable boxes cover a wide range of product types such as eye shadow, mascara, lipstick and foundation, and can be easily disassembled and reassembled, so that when a consumer uses up a cosmetic product and makes a return purchase, they no longer need to buy the product with a new box, but can simply buy the cosmetic "core" at a cheaper price and put it into the original box itself. In addition, on top of the traditional metal make-up case, the company has designed a special case made of biodegradable and compostable paper material. Consumers who choose this packaging can not only refill it again and again, but also do not have to worry about causing pollution when throwing it away.

In promoting this sustainable cosmetic packaging to consumers, Kjaer Weis also took care to express its selling point, not by emphasizing environmental issues, but by combining the concept of sustainability with the "pursuit of beauty" that cosmetics represent, conveying to consumers the value of "beauty for people and the planet". Of course, the most important thing is that it provides consumers with an absolutely valid reason to buy: cosmetics without packaging are just more economical.

Consumers' choice of product packaging is changing little by little. How to grab the attention of consumers in the new era and explore new business opportunities by improving packaging design and working to reduce waste is a question that all companies must start thinking about nowadays, because "sustainability" is not a temporary popular element, but the present and future of brand companies.