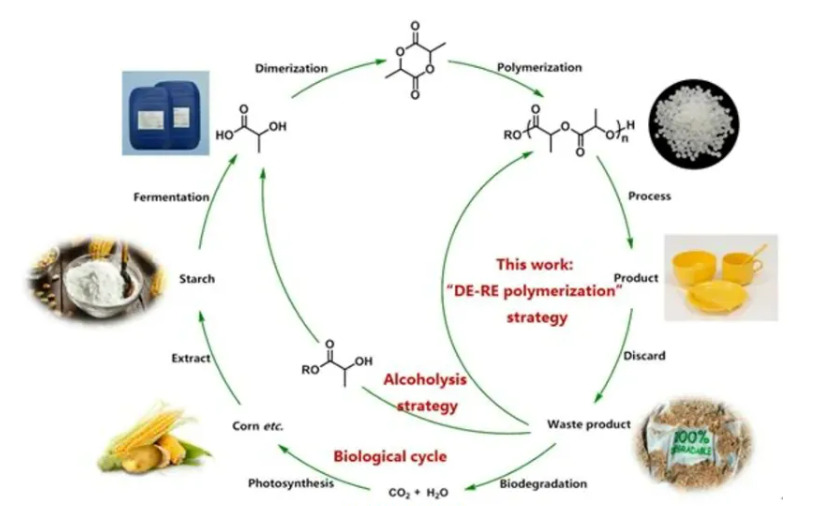

Polylactic acid (PLA), as a typical polymer material derived from renewable raw materials (starch), is gradually developing into a basic bulk material necessary for society. At the same time, the post-processing of used PLA materials has attracted attention. Although PLA can be degraded in nature, the process usually requires a long time and specific degradation conditions, and the degradation products are carbon dioxide and water, which cannot be directly and rapidly recycled, and is essentially a carbon emission process and a waste of resources. The recycling of PLA by means of chemical recycling provides an effective solution for the reprocessing of waste PLA. Most of the current research is to convert waste PLA to alkyl lactate, but cycling through this process to obtain high molecular weight PLA materials requires hydrolysis of alkyl lactate into lactic acid, prepolymerization into oligomers, dimerization into propyl cross esters and then polymerization to obtain PLA, which are feasible but costly and inefficient (shown in Figure 1). Therefore, realizing the direct conversion of waste PLA materials into new PLA materials has important research value and application prospects.

Figure 1 Polylactic acid cycling strategy

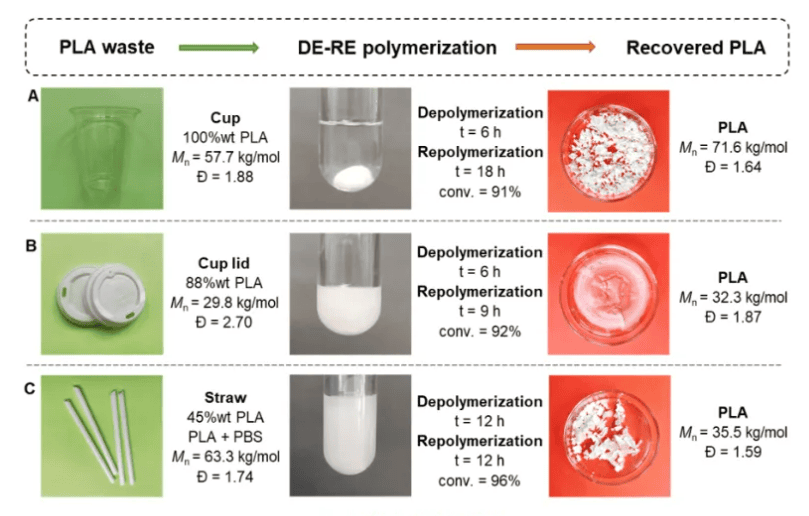

The Catalytic Polymerization and Engineering Research Group led by Qinggang Wang at the Qingdao Institute of Energy, China, has developed a new upcycling strategy of polymer degradation and re-polymerization (“DE-RE polymerization” strategy) to successfully realize the recycling process from PLA waste to new PLA materials in a “polymer-to-polymer” manner (shown in Fig. 2). A new upcycling strategy (“DE-RE polymerization” strategy) has been developed by the Catalytic Polymerization and Engineering Research Group, led by a researcher from the Catalytic Polymerization and Engineering Research Group.

The mild reaction conditions and few side reactions of this strategy reduce the consumption of raw materials for the complete reproduction of PLA and maximize the recycling efficiency of PLA. During the re-polymerization process, final materials with different properties can be obtained by adding different types of monomers. The results provide a new solution idea for the recycling of PLA and promote the development of a sustainable society.

In addition, this strategy is not only effective in chemical recycling, but also promising in polymer modification and synthesis.

Fig. 2 Chemical recycling of PLA waste plastics