Reducing carbon and emissions has been a must for the automotive industry in recent years to realize sustainable development. Recently, many chemical manufacturers have launched recycled or bio-based automotive plastics to help automotive manufacturing sustainable development from the material side.

Centrio: Injection Molding Grade Recycled and Bio-based Resins

Trinseo recently introduced Altuglas R-Life V825T acrylic resin and Magnum bio-based ABS resin (95% bio-properties) with recycled content. Both resins can be used for molding automotive parts.

Altuglas R-Life V825T is described as a sustainable line of injection molding grade acrylics. It is widely used in automotive and other applications. The resin is available in clear, red and black colors.

These resins are available from chemically or mechanically recycled feedstocks and offer excellent optical properties, UV stability, scratch resistance and colorability consistent with their new counterparts.

The Altuglas R-Life V825T has at least 35% recyclables for mechanical recovery and 50% for chemical recovery.

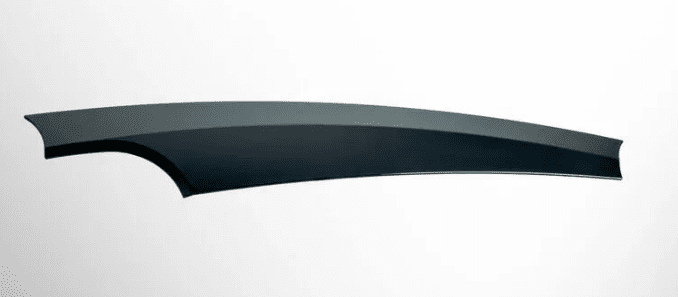

Centurion Altuglas R-Life V825T is a sustainable line of injection molding grade acrylics.

Magnum bio-based ABS resins, on the other hand, are produced by blending bio-based raw materials with fossil polymers in a polymerization process based on the ISCC+ mass balance principle.

The material is structurally and functionally identical to petroleum-based materials and can be used with existing tools and equipment without the need for material re-qualification.

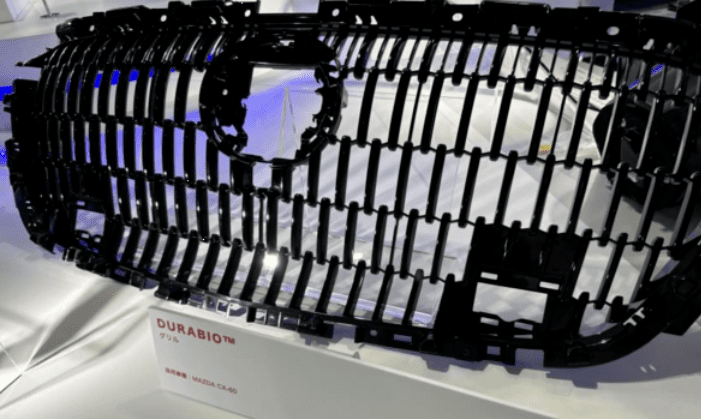

Mitsubishi Chemical: Bio-based engineering plastics used in Mazda grille

Mitsubishi Chemical's bio-based engineering plastic (polycarbonate-based), DURABIO™, uses isosorbide, a renewable plant-derived raw material, as its main ingredient.

Mitsubishi Chemical's bio-based engineering plastics have been used in Mazda grille manufacturing

DURABIO™ is said to quantify higher environmental performance than other petroleum-based engineering plastics, such as LCA, because its main raw material is derived from plants, and, depending on the part, the environmental impact can be reduced by eliminating secondary processes such as painting.

Mitsubishi Chemical says the bio-based material has a good balance of physical properties in terms of transparency, weatherability, scratch resistance, impact resistance and optical properties. It is currently used in the grille of the latest Mazda.

Huntsman: Polyurethane with 20% bio-based content

Huntsman has introduced Acoustiflex VEF BIO, a polyurethane with up to 20 percent vegetable oil bio-based content, which can be used for molded acoustic applications in the automotive industry.

Huntsman bio-based polyurethanes can be used for automotive carpet back foam instrument panels, wheel cover arch insulation.

This new solution reduces the carbon footprint of foaming the back of automotive carpets by 25%. The technology can also be used for dashboard and wheel cover arch insulation.

Huntsman says the biological component of its Acoustiflex VEF bio system has no impact on any acoustic or mechanical properties required by component manufacturers or automotive OEMs.