World fish production is estimated at 177.8 million metric tons in 2019 and is expected to grow significantly in the future. Fisheries and aquaculture play an important role in food security and nutrition, as widely recognized by the UN 2030 Agenda for Sustainable Development and FAO. Approximately 70% of fish and seafood are processed prior to sale, thus generating large amounts of solid waste from activities such as decapitation, shelling, gutting, finning and scaling, and filleting.

Fishery by-products typically include viscera, muscle tissue, carcasses, heads, fins, skin, scales and bones, and account for approximately 50% to 75% of the fresh weight, depending on the species. For example, the processing of shrimp and fish fillets generates almost 50% and 75% by weight of the waste. About 20% of fishery by-products are used as low-value components in animal feed, and most are landfilled or incinerated, resulting in environmental, health, and economic losses.

Fish waste is therefore a growing problem that urgently requires innovative approaches and solutions. For this reason, several projects and measures have been adopted worldwide to prevent food waste. Among them, fish waste is attracting increasing attention as a new raw material for bioplastics in different applications (mainly food packaging), with significant economic and environmental advantages.

By recovering several potentially valuable molecules (including oils, proteins, pigments, bioactive peptides, amino acids, collagen, chitin, gelatin) it is possible to make them into food packaging. Packaging can still be considered a major segment for bioplastics production, accounting for 47% (0.99 million tons) of the total bioplastics market in 2020. Among these innovative green materials, edible/biodegradable films for food packaging applications have attracted the attention of researchers in academia and industry.

From, Francesca Leonetto, Department of Innovation Engineering, University of Salento, et al. published in Polymers

The review article titled 'Recent applications of biopolymers from fish industry waste in food packaging' summarizes recent advances in the valorization of fish industry waste and the potential to reuse these by-products in a circular economy approach for the preparation of bioplastics for food packaging.

1. Muscle protein

Muscle proteins are divided into three major categories based on their solubility: myogenic fibronectin, sarcoplasmic proteins, and matrix proteins. Myogenic fibronectin is the main component of skeletal muscle, accounting for approximately 65-75% of total muscle protein. Myogenic fibronectin includes a number of contractile proteins such as myosin and actin, regulatory proteins such as promyosin and troponin, and other minor proteins. Due to their structure and localization, myofibrillar proteins require denaturing conditions, such as high ionic strength solutions to be solubilized and extracted.

Proteins are one of the most commonly used biomaterials in the food industry because of their nutritional value, non-toxicity, biodegradability and ability to form gels. In recent years, fish matrix proteins and myofibrillar proteins have received great attention due to their ability to form biodegradable edible films with good barrier properties to gases, organic volatiles and lipids, which are insoluble in water but can be dissolved by adjusting the pH of the solution. These films made from fish myogenic fibers or muscle proteins have several advantages. (i) Excellent UV-blocking properties compared to commercial packaging films made from PVC. (ii) good oxygen and carbon dioxide barrier; (iii) slight transparency; (iv) potential to produce reactive packaging.

The main drawback limiting the widespread commercial application of these films is the stiffness and low mechanical strength due to the extensive protein-protein chain interactions in the film network which further enhance disulfide, hydrogen and/or electrostatic interactions. To overcome this problem, high levels of plasticizers (~40-60%) can be added to biodegradable films to reduce brittleness and increase ductility and toughness by reducing the force between protein-protein chains. Another limitation of fish myofibrillar protein membranes is the poor water vapor barrier due to the high hydrophilicity of the amino acids in the protein and the addition of large amounts of hydrophilic plasticizers (such as glycerol and sorbitol) to give the membrane sufficient flexibility . Chemical cross-linking, electron beam and gamma radiation are reported to be effective methods for obtaining stronger and less permeable films .

2. Marine collagen

Collagen is the most common animal protein because it is found in all connective tissues (i.e. skin, bone, ligaments, tendons and cartilage) and in the interstitial tissues of parenchymal organs.

Marine collagen is mainly extracted from fish skin, fish bones, fins, scales or connective tissue of jellyfish, sea urchins, sea stars or sea cucumbers. Fish skin has been used to extract collagen because 70-80% of its dry matter is collagen. In addition, fish scales are another promising and low-cost source of marine collagen, accounting for about 4% of the total annual production of fish offal, or about 18-30 million tons. Fish scales contain both organic components (collagen, fat, lecithin, hard protein, various vitamins, etc.) and inorganic components (hydroxyapatite, calcium phosphate, etc.).

Compared to mammalian collagen, marine collagen has a comparable or slightly lower molecular weight and a lower denaturation (melting) temperature, which is about 20-35°C for most fish, while collagen values from warm water species are higher. Suitable cross-linking treatments have been investigated in order to improve thermal stability.

According to Coppola et al. the dry mass of collagen extracted from fish by-products can reach more than 50%. In addition, the de-oiling of the fish during processing ensures that there is no odor or taste. Extraction of collagen from fish scales by chemical methods often takes a long time. Therefore, the interest of researchers in a suitable process for the extraction of fish scale collagen is increasing.

Compared to mammalian collagen, marine collagen does not have restrictions on its use for religious reasons and possible infectious diseases, while offering excellent film-forming ability, biocompatibility, low antigenicity, high biodegradability and cell growth potential. This waste material has the potential to be developed as an environmentally friendly and low-cost source of collagen with many potential applications as a drug/delivery vehicle or wound dressing in various fields such as health food, cosmetics and biomedicine. Due to its high water absorption capacity, collagen is a good candidate for texturization, thickening and gel formation. In addition, it has interesting properties related to surface behavior, including emulsion, foam formation, stabilization, adhesion and cohesion, protective colloid function and film-forming ability. Although it has been used as a food additive to improve the rheological properties of foods, marine collagen has not been fully exploited and its application is much less than that of mammalian collagen.

The use of fish collagen films in the packaging industry is limited by several drawbacks, such as low thermal stability and relatively poor mechanical properties. In addition, collagen is a hydrophilic polymer with hydroxyl groups. As a result, water vapor can easily pass through the film. Various efforts have been made to overcome these limitations, including mixing collagen with other biopolymers and several chemical and enzymatic treatments.

For example, Ahmed et al. The use of a mixture of collagen and chitosan extracted from leather jacket skins enhanced the antibacterial ability and antibacterial activity of the film, but affected the elasticity or brittleness of the film.

3. Fish glue

Gelatin is a denatured protein derived from the partial hydrolysis and heat treatment of collagen. It consists of a group of proteins and peptides of different molecular weights, whose composition depends mainly on the parent collagen and the extraction procedure.

During hydrolysis, the natural molecular bonds between individual collagen chains are broken down, leaving a mixture of single- or multi-chain polypeptides, each with an extended leptospiral conformation and containing 50-1000 amino acids. Two types of gelatine, type A and type B, were obtained by acid hydrolysis and alkali hydrolysis, respectively.

The extraction and application of gelatin from fish faeces has attracted widespread interest due to religious issues and concerns about the spread of disease to human health. Gelatin is an important industrial biopolymer with remarkable gelling and film-forming properties for use in food, pharmaceutical and other related fields.

Due to its good film-forming properties, low cost, biocompatibility and biodegradability, fish gelatin has recently been recommended for the preparation of biodegradable films in reactive food packaging to replace traditional non-biodegradable polymers and other mammalian-based gelatins. Gelatin is easily processed by applying thermal and mechanical stresses in an extrusion-based technique. To increase flexibility, plasticizers are used as internal lubricants, which improve molecular mobility. Gelatin aqueous solutions can be cast to obtain gelatin films.

They are odorless, colorless, transparent, water-soluble, and more flexible than other bio-based films used in food packaging. Since the melting point of gelatin is close to body temperature, gelatin-based films can be used to prepare edible films. In addition, fish gelatin has shown great potential as an excellent matrix for bioactive compounds with enhanced functionality, such as antioxidants/antibacterial agents.

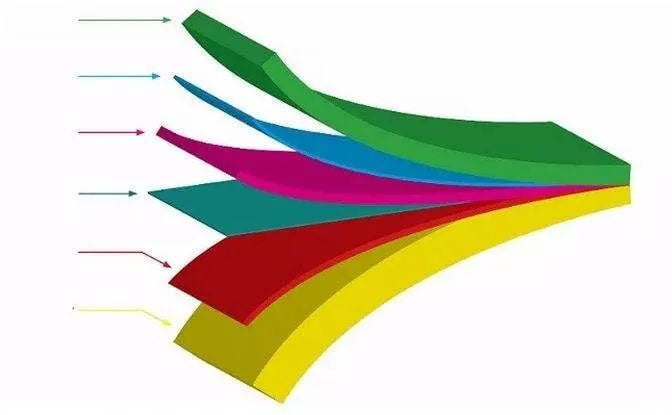

Water resistance is improved by laminating fish gelatin films with moisture-resistant biodegradable polymers in a multilayer film that has moisture and oxygen barrier layers optimized for specific packaging and conditions. Martucci et al. A three-layer gelatin film was heat pressed using sodium montmorillonite plasticized gelatin as the inner layer and cross-linked dialdehyde starch and plasticized gelatin film as the outer layer. The multilayer film shows a compact and homogeneous microstructure due to highly compatible individual layers that can interact through strong hydrogen bonds. The same authors also prepared a multilayer structure in which a PLA film served as an outer layer with higher water vapor permeability than other commercial polymers such as high-density polyethylene or polyvinyl chloride.

Another promising approach to improve the barrier, mechanical and thermal properties of fish glue for food packaging is based on cross-linking. In particular, natural-based crosslinkers have attracted more attention in order to take into account environmental and health concerns as well as economic issues, as reviewed by Garavand et al. A scheme for cross-linking fish gelatin with citric acid was developed by iguori et al. Heat treatment in the presence of reducing sugars (called the Merad reaction) has been shown to lead to cross-linking processes and altered network structure. Recently, Maroufi et al. demonstrated the chemical cross-linking of fish gelatin with the aldehyde group of K-carob gum.

4. Application of chitosan in food packaging

Chitin, the second most abundant biopolymer in nature after cellulose, is a linear polymer, or polysaccharide, located in the cell walls of fungi and in the exoskeletons of plankton, crustaceans and insects, in the form of ordered crystalline microfibrils, and these organisms produce about 100 billion tons of chitin per year.

The biocompatible, non-toxic and biofunctional properties of chitin and chitosan biopolymers make them potentially suitable for food packaging applications. In particular, chitosan biopolymers derived from shrimp are pre-determined to be Generally Recognized as Safe (GRAS). On the other hand, chitosan is much cheaper compared to other biopolymers. Nevertheless, the excellent properties of chitosan make it more suitable for food packaging applications. For example, an extension of the shelf life of bread was successfully proposed, as it was shown to retard starch regrowth by preventing microbial growth.

Tyliszczak et al. demonstrated that chitosan films can also preserve strawberries. In addition, Zakaria et al. demonstrated that chitosan films inhibit the alteration of physical properties of vegetables. Chitosan can also be used to produce food wrappers coated with it, thus retarding the growth of microorganisms. Strategies to improve the performance of chitosan films for food packaging are almost identical to those used for fish gelatin films. In fact, the development of polymer blends represents an effective way to improve mechanical properties and reduce water solubility and water vapor permeability. Several polysaccharides have been added to chitosan for the production of hybrid films with enhanced end properties for food applications. Among them, starch is one of the most common polysaccharides proposed for the production of chitosan-based biofilms due to its low cost, wide availability and biodegradability.

Chitosan/starch films have demonstrated reduced bacterial adhesion, excellent antioxidant activity and increased water vapor barrier properties in packaging, thus proving their potential suitability for specific applications. Several scientists have investigated the possibility of preparing cellulose/chitosan blends to improve the mechanical properties of pure chitosan .

Conclusion

Fish industrial waste has shown its great potential as a new raw material for the production of biopolymers that can be used in different applications, mainly in food packaging. Value-added utilization of fish waste is economically advantageous because it helps to reduce the cost of safe waste disposal and generates additional value through the recovery of several potentially valuable molecules. In addition, the value added by fish by-products brings some environmental advantages that come from the reduction of landfills, incineration and discards, which constitute a serious waste of resources, as well as from the substitution of fossil-based polymers. In this way, the recycling of fishery waste can have a positive impact on the ecosystem and the financial viability of the fishery. Its impact is expected to increase in the coming years.