With the implementation of the concept of sustainable development, public awareness of environmental protection, people's demand for environmentally friendly products in a significant increase.

This also urges companies to gradually reduce their dependence on non-renewable resources in their production processes. To reduce the overall carbon footprint, bio-based materials are increasing in packaging use year by year.

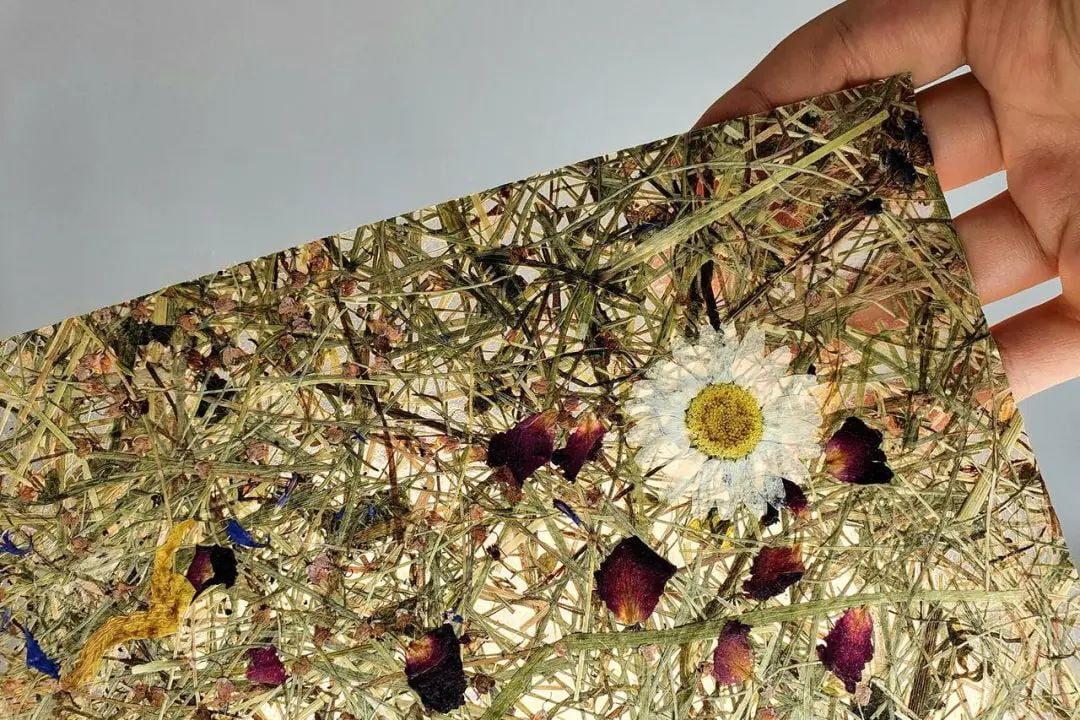

Organoid, a package made of natural plants and alpine hay

In line with this growth, brands can draw inspiration from agricultural waste and other industry tributaries. Bio-based materials, on the other hand, play a key role in future development as an alternative to non-renewable materials that can produce aesthetically pleasing products and enhance environmental potential.

Notpla

Tree Free Fiber

Reducing the paper industry's reliance on wood, tree-free fibers are becoming more prominent and plant-based materials, including agricultural fertilizers and industrial byproducts, are emerging as leading players. With global consumption of paper and paperboard totaling 408 million tons last year, there is an urgent need to source paper-based materials from plant waste, residues and by-products to replace traditional wood fibers.

British packaging manufacturer DS Smith is testing a new paper packaging production process that uses agricultural waste and annual plants such as straw, hemp and manzanita to reduce pressure on forests. Similarly, Austrian company Organoid uses untreated natural plants, such as alpine hay and mint stems, to create luxury packaging materials.

DS Smith launches paper products made from agricultural waste such as rice straw, hemp and manzanita

French fashion brand Chanel has released a limited edition molded blister pack made of 60% FSC certified bamboo and 40% bagasse fiber. Bagasse fiber is a by-product of the sugarcane industry, a material known as an ecological material that is both recyclable and biodegradable.

Chanel

Food waste

Houbly, a French company, uses cocoa pods, a residue from the chocolate production process, and beer waste grains from the beer brewing process to create bio-based packaging. Looking to China, startup Mi Terro has established a partnership with Budweiser in China to create a biodegradable film from the grain left over from the beer production process.

Discarding food waste in large quantities can have a negative impact on the environment, the economy and future food security. Instead, we reuse it as a resource and turn it into a valuable resource with great potential, why not.

Mi Terro, a biodegradable film made from grains used in the beer-making process

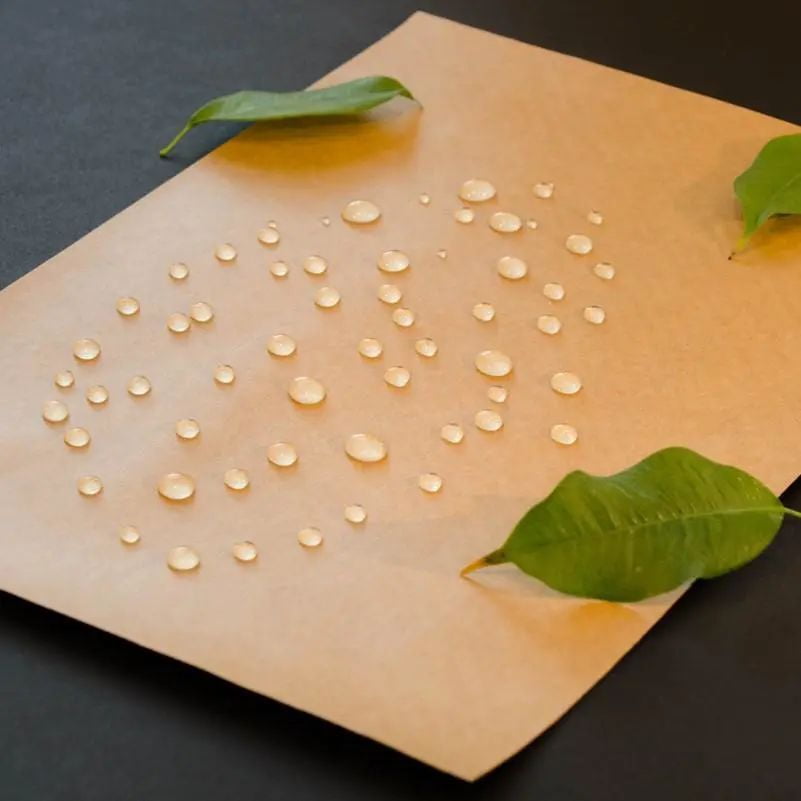

Bio-based Barrier Materials

Through innovations in material properties, bio-based barrier coatings are gradually reaching new levels of technological performance that are comparable to traditional petrochemical alternatives.

For example, CelluloTech, a Canadian materials science company, has developed a chemical reaction process that makes paper and other bio-based materials such as starch and minerals superhydrophobic while maintaining their recyclability. This results in a single bio-based material with high performance and long-lasting barrier properties.

More and more new environmentally friendly materials are emerging, and innovation in materials science will shape a better and broader future for the industry.