Petroleum-based plastics, a large category of resources derived from petroleum, consume huge amounts of petroleum, and the Environmental Footprint Assessment of Plastics states that global plastics production will consume 20% of the world's petroleum by 2050. Among the plastics, polyolefins occupy about 45% of the total plastics, followed by polyester, the main varieties include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), etc. One of the important applications of these polyolefins and polyesters is the packaging industry. As the supply of petroleum resources becomes increasingly tight, scientists, governments and related companies are developing renewable resources to reduce the consumption of petroleum resources. Biobased materials are a class of products whose raw materials are wholly or partially derived from plants and are often explained in the research field by a large number of terms, such as "plant origin", "new carbon" or "organic carbon".

Bio-based materials can be divided into degradable bio-based materials and non-degradable bio-based materials, which are a class of green materials with broad development prospects and application potential. Biodegradable bio-based materials include polylactic acid, starch-based materials, and polyhydroxyalkyl ester group polymers.

Non-degradable bio-based materials are more mature than degradable bio-based materials, mainly including bio-based PE (Bio-PE), bio-based PP (Bio-PP) and bio-based PET (Bio-PET). These materials are sourced from renewable energy sources rather than petrochemical raw materials. Compared with traditional petroleum-based plastics, they have the ecological advantage of a smaller carbon footprint and lower resource consumption, and are an important way to achieve a circular economy, energy conservation and emission reduction.

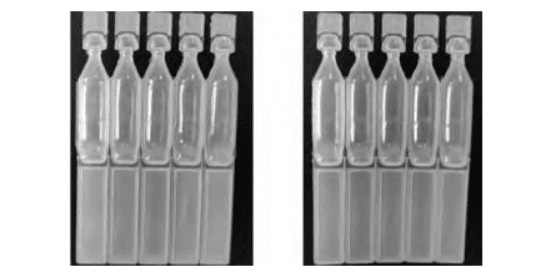

Petroleum-based PE (left) Bio-PE (right)

Bio-based materials can be obtained from different biological materials such as starch and lignocellulosic materials from sugarcane, sugar beet, corn, wheat or other grains. In line with petroleum-based PE, Bio-PE is also polymerized from ethylene monomer, the difference is that the ethylene monomer of Bio-PE is obtained from biomass materials, and its preparation process starts with obtaining glucose from biomass materials such as sugarcane, sugar beet and corn, and these glucose are fermented to obtain bioethanol, and bioethanol is then distilled, dehydrated and catalyzed to obtain bio-based ethylene monomer, which is then polymerized to Bio-PE. Plastics are very versatile due to their low cost and versatility. Among the many applications, packaging accounts for 40% of the plastics consumer market, followed by construction, automotive and household appliances.

Today, most of the materials used in the packaging industry come from petrochemical raw materials and their use cannot be underestimated, resulting in a large amount of packaging waste, which according to statistics, generated about 177.4 kg per inhabitant in 2019, with plastics accounting for about 20% of the total packaging waste, an increase of 13.3 million t (+20.1%) compared to 2009. The packaging industry's choice of green materials from the source, such as plastics of bio-based origin or fully degradable plastics, is an important driving force in accelerating the process of low-carbon environmental protection and reducing the consumption of petroleum resources.

To further greenize cosmetic packaging materials to reduce carbon emissions, trials were conducted related to the application of bio-based low-density polyethylene (Bio-PE) instead of petroleum-based low-density polyethylene (petroleum-based PE) in cosmetic packaging materials. Firstly, the biological origin of Bio-PE was verified and the physical parameters of Bio-PE and petroleum-based PE were compared. The results showed that the physical parameters of Bio-PE and petroleum-based PE are comparable, therefore, the process parameters applicable to petroleum-based PE processing are also applicable to Bio-PE.

Further, Bio-PE and petroleum-based PE were processed into cosmetic sub-disposable packaging materials using a three-in-one aseptic filling equipment with blow-fill-seal, and the performance of these two sub-disposable packaging materials was compared, including water vapor transmission rate, oxygen transmission rate and total migration under three different simulated environments. The results showed that the barrier properties and the total migration of Bio-PE and petroleum-based PE sub-polymer packages were generally comparable under the three different simulated environments.

Subsequently, Bio-PE was tested for skin irritation and skin sensitization according to medical device related biological evaluation methods, and the results showed that Bio-PE does not cause skin irritation and sensitization reactions. Finally, the compatibility of Bio-PE sub-disposal packages with cosmetic inner materials was investigated, and it was demonstrated that Bio-PE does not affect the appearance, pH and viscosity of cosmetic inner materials, and the relative cellular value-added of serum soaked with Bio-PE does not increase compared with petroleum-based PE. Therefore, Bio-PE can be used instead of petroleum-based PE in cosmetic packaging materials.