When people's bones break, they can be repaired by both external and internal fixation. After fixation, the bones can repair themselves over time.

External fixation requires the use of a cast, which is wrapped around the outside of the body to prevent the bone from shifting; however, the cast can limit the patient's mobility, so internal fixation is a popular medical strategy today.

Internal fixation can be done with plates and screws that can be surgically removed after the bone has healed, but this adds to the patient's pain.

Biodegradable plastics can meet a variety of functional requirements for medical devices, and they are increasingly being used in the medical field.

PCL is a widely used synthetic polymer whose properties are being explored for biomedical applications. In addition, PLA and PCL exhibit excellent biocompatibility and biodegradability. In addition, they are non-toxic and degrade at a controlled rate once injected into the body. Compared to PCL, glassy PLA is more brittle and breaks down faster, and its flexibility and softness are reduced; however, because PCL has a low surface energy, there is no attachment signal, and as a result, fewer cells adhere to the surface. In order to create new biomaterials that go beyond the role of each polymer alone, the two polymers can be effectively combined.

Although PCL and PLA are compatible, studies have shown that there is only a relatively weak link between the two materials when combined using a melt blending process. According to Broz et al. (2003), PCL copolymers with PCL concentrations above 50% showed increased interactions between PLA and PCL. In addition, Zhai et al. (2009) found that the optimal PCL and PLA mixing ratio was PLA70/PCL30.

Researchers at Diponegoro University, Indonesia, investigated the effect of PCL concentration on the properties of PLA polymer blends, and they prepared PLA/PCL blends by ball milling, pressing and sintering, which is expected to improve the strength of PLA/PCL blends and produce good interfacial bonding.

This is done by mixing PCL and PLA with different concentrations for 2 hours using a ball mill at 80 rpm. The obtained mixture is placed in a stainless steel 304 mold for the compaction process, which uses a pressure of 30 MPa to create the blanks.

The sintering procedure was performed for 2 hours using a digital oven on raw blanks produced at 150°C. PLA/PCL blends obtained using Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM), density, porosity, and three-point bending tests.

It was shown that the increase in PCL content resulted in rougher surfaces with many voids and flakes in 90PLA, 80PLA, 70PLA and 60PLA samples.

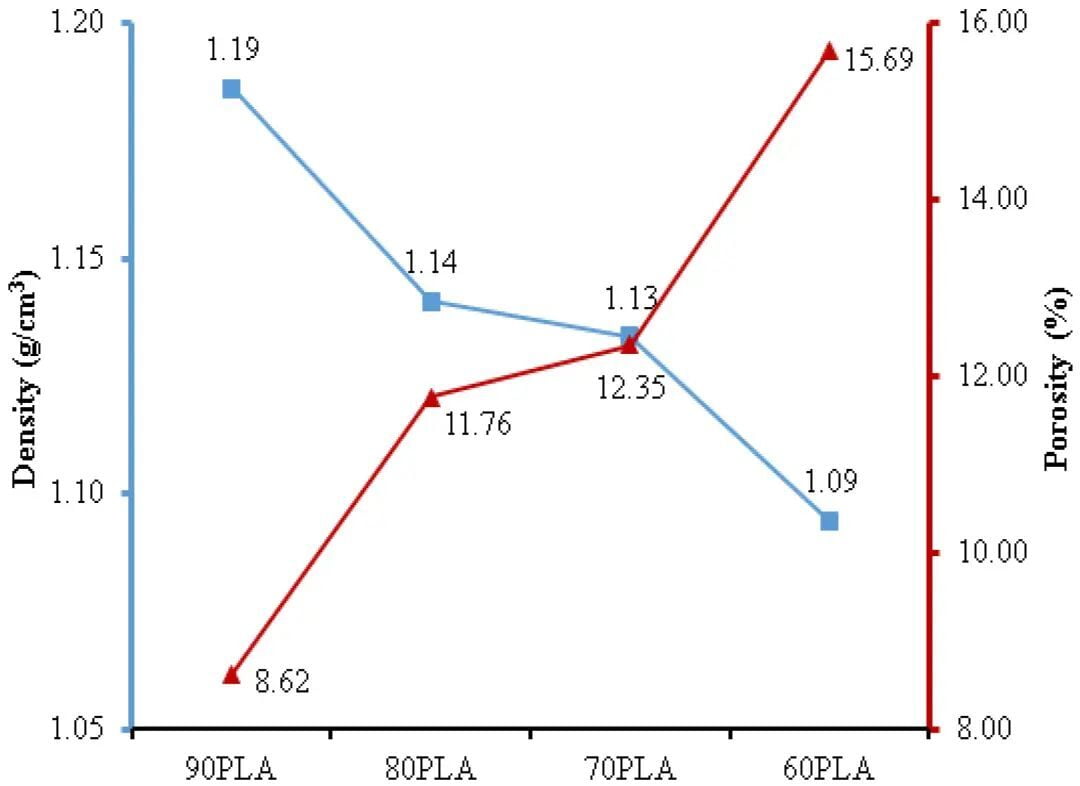

This proves that the plastic deformation increases with the increase of PCL content. The mixing ratio has a significant effect on the values of bulk density, apparent density and porosity.The porosity of PLA/PCL blends decreases with increasing PLA concentration.

Density and porosity of poly(lactic acid) (PLA) and polycaprolactone (PCL) blends.

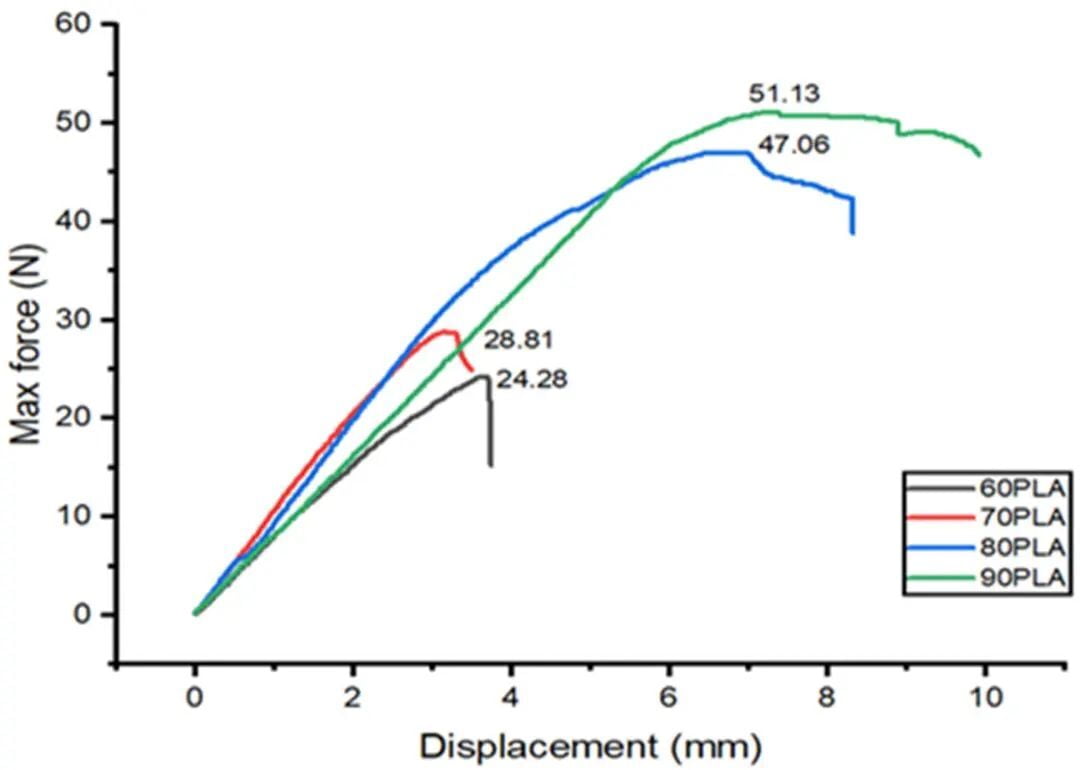

In addition, the density of the PLA/PCL blends increased linearly with increasing PLA content.90 The PLA samples had the highest density (1.19 g/cm3) and the least porosity (8.62%). The flexural strength of PLA/PCL blends increases with their density. The 90PLA sample had the best mechanical properties with a maximum force and displacement of 51.13 N and 7.21 mm, respectively.The addition of 10 wt% PCL improved the stress transfer and allowed the formation of a stiffer bond, which contributed to the improvement of the flexural properties of the PLA/PCL blend. In addition, high PCL content reduces the stiffness of PLA molecular chains, leading to a decrease in bending performance.

Bending test results of PLA/PCL blends