Researchers at the University of Birmingham are exploring the potential to depolymerize PHA at the end of life

PHAs, or polyhydroxyalkanoates, are a family of biopolyesters produced in nature by many microorganisms. They are synthesized directly through the fermentation of carbon substrates within microorganisms, which include sugars and lipids, sewage water, coffee grounds, or methanol, and are stored as insoluble particles within the cell as energy and carbon reserves. PHAs are synthesized by microorganisms under nutrient deficient conditions. They are separated from the microorganisms with the help of a solvent; the solvent is then removed and the harvested PHAs are washed, dried and pelletized through an extruder.

Not only does PHA come from renewable sources, but it is also compostable, biocompatible, and fully biodegradable - in soil and water. Given this range of end-of-life options, recycling PHA may not be the first option on the agenda. However, a team of researchers at the University of Birmingham in the UK thinks otherwise, and is working to create a circular economy for bioplastics by exploring the potential for depolymerizing PHAs at the end of their life.

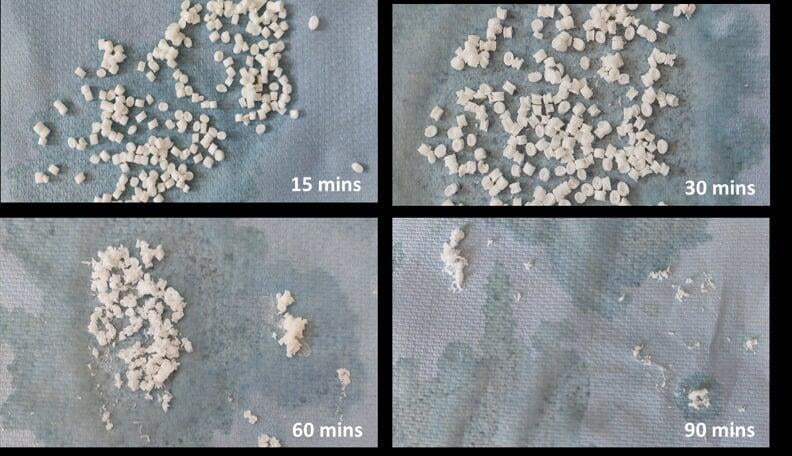

University of Birmingham, P3HB particles decompose by depolymerization

The "Recycling PHA for Second life" (RePHASe) project investigates hydrolysis as a PHA depolymerization technique. Scientists are investigating whether the process can be scaled up using a continuous unit in which water and catalyst are preserved and recycled back into the process. The process has been demonstrated in small batches.

The team will use design software to map out the complete chemical process, heating and total energy requirements, as well as demonstrate the full process design on an industrial scale. They will use Life Cycle Analysis (LCA) and Techno-Economic Assessment (TEA) to determine if scaling up the process is technically and economically feasible.

Two undergraduate researchers have conducted a case study on P3HB, one of the most common types of PHA. Their project found that immersing the polymer in methanol for 12-16 hours and then allowing it to dry halved the depolymerization time, which may reduce resource consumption.

In the future, RePHASe's team hopes to secure funding to study the engineering requirements to scale up the process to commercial scale.