On September 26th, Christian Garaffa, Marketing Manager of Novamont, Italy, shared on the topic of "End-of-life treatment solutions for compostable plastics in Europe".

1. Focus on bio-based, actively develop bio-based degradable materials

Founded in 1989, Novamont, with its origins in the Monte Dixon Institute of Materials Science and its headquarters and research center in Novara-Piedmont, Italy, is the leading Italian company in biodegradable materials technology. With an annual turnover of more than €270 million and 600+ employees, it currently has nine Mate-Bi (PBAT modifier) lines, six Origo-Bi (PBAT polyester) lines, a plant for the production of Matrol-Bi (bio-based lubricants) and a plant for the fermentation of bio-based BDO (30,000 tons in size).

Bio-based BDO

In 2016, Genomatica helped Novamont, an Italian company that produces biodegradable plastics, to start the construction of a plant with an annual capacity of 30,000 tons of bio-based BDO for the production of bioplastics. This is currently the largest bio-based BDO capacity in the world.

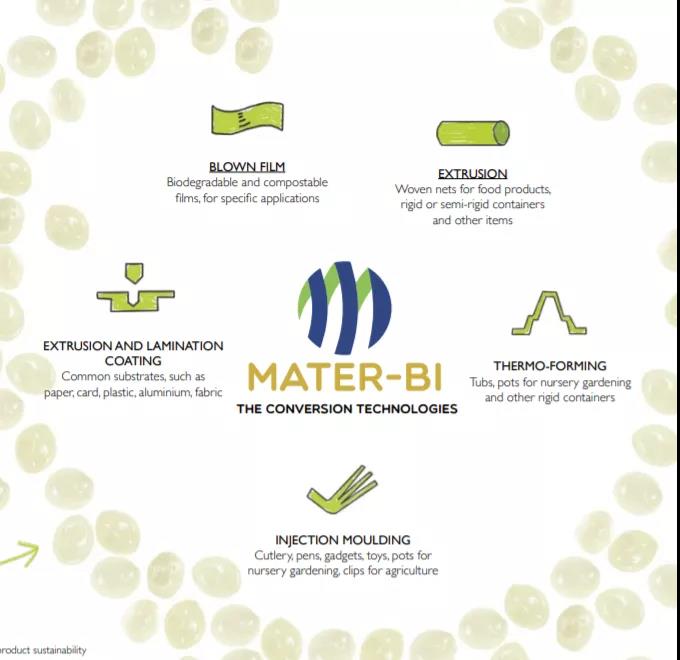

Mater-Bi (PBAT modified material)

In 2004, NOVAMONT (Italy) acquired "Eastar-Bio" co-polyester biodegradable plastics business from Eastman (USA), with PBAT trade name "Origo-Bi" and production capacity of 100,000 tons/year. Previously, Eastman also licensed BASF's PBAT patent. Later, Novamont launched a modified degradable plastic "Mater-Bi" by blending PBAT/starch with a capacity of 200,000 tons/year, which is the main product of Novamont. Mater-Bi materials contain starch, cellulose, vegetable oils and other substances with a bio-based content higher than 60%.

MATROL-BI (Bio-based lubricant)

MATROL-BI is a line of bio-lubricants and rapidly biodegradable greases derived from renewable resources. Since it comes from renewable energy sources, it is rapidly biodegradable and can effectively replace petroleum-based products, reducing environmental risks in the ecosystem.

CELUS-BI (Cosmetic products)

CELUS-BI is a new line of innovative bio-based ingredients for the cosmetic industry, developed thanks to NOVAMONT's research.

Downstream applications for this product include: moisturizers, shampoos, foundations, and lipsticks are just a few examples of the many applications of these innovative bio-based ingredients that combine high performance with low environmental impact.

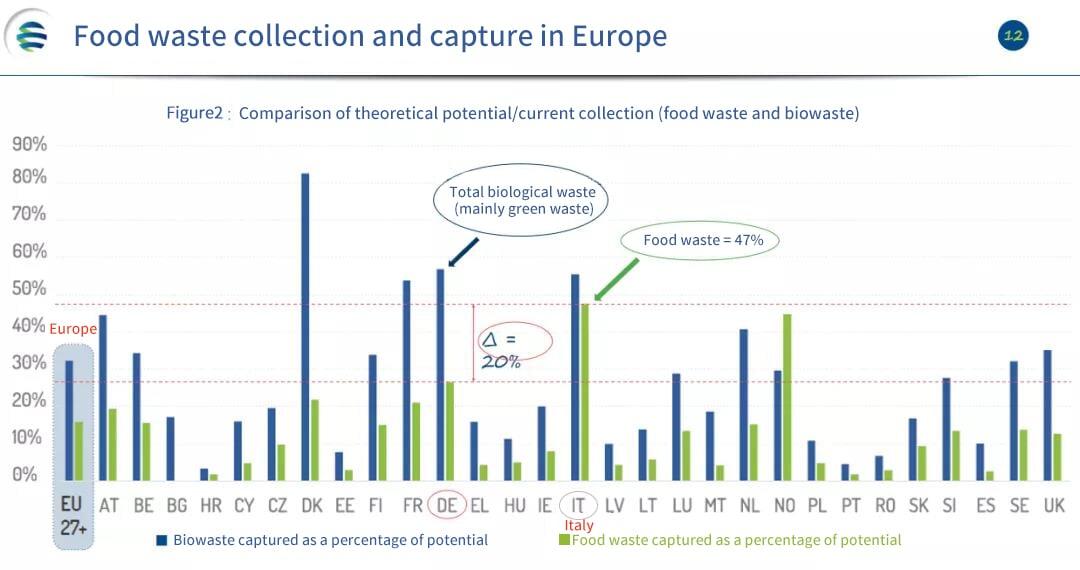

2. The current situation of food waste separation and collection in Europe

The circular economy and bioeconomy represent a new economic paradigm for the sustainable use of renewable resources. The circularity of the food system is an integral part of this. Ecological design of the waste stream and product end-of-life phase is a key aspect in order to effectively and efficiently convert waste into resources. In this segment, compostable packaging is significant as single-use packaging that can be achieved together with organic waste.

The EU has set its own circular economy targets of 55% total municipal waste recycling by 2025, 60% by 2030 and 65% by 2035, as well as mandatory collection of bio-waste by 2023 and a 10% reduction in all waste going to landfill by 2030. In order to achieve this goal, it is first necessary to establish efficient collection systems with high capture and low contamination of non-compostable materials (mainly plastics). That is, separate waste collection systems.

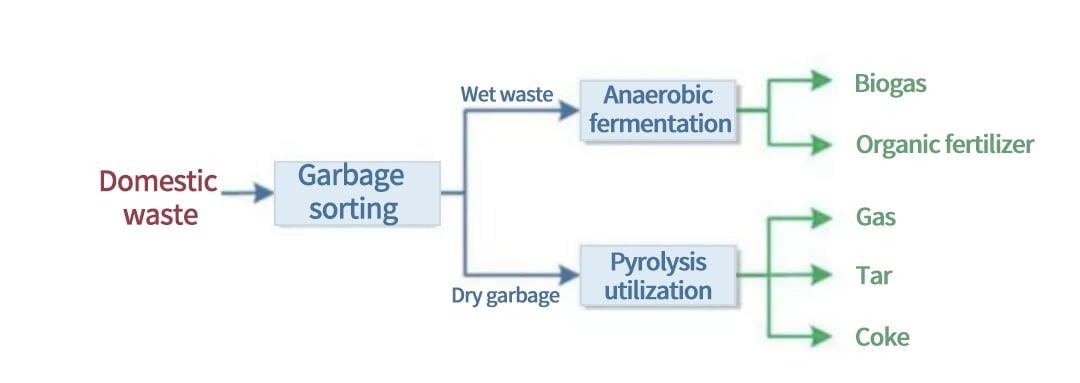

The second is the establishment of modern treatment facilities for organic waste (anaerobic digestion and integrated composting) to reduce organic waste disposal residues, produce methane (anaerobic fermentation) and high-quality compost free of microplastics, and enable the recycling of compostable packaging. The compost formed from the final organic waste will be used to restore soil fertility and close the loop.

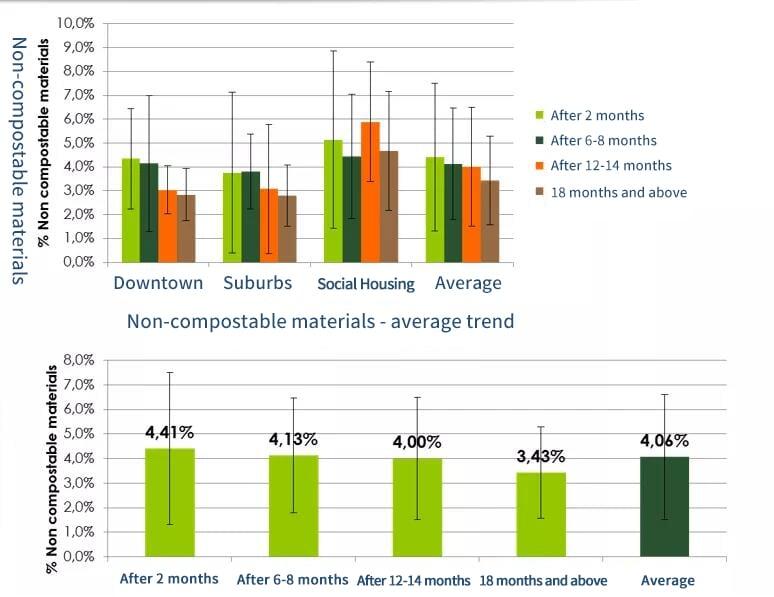

The Italian city of Milan launched the collection and sorting of food waste in 2013, and its composting and biogas association conducts an analysis of waste composition every six months. It was found that as the sorting move continued, the proportion of non-compostable materials in food waste became less and less, and the effect of sorting was significant.

3. Application value of compostable plastics

The value of "compostable plastics" lies in the fact that the back-end processing can achieve a closed-loop application (nutrient cycle), which truly realizes the recycling of plastics. Facilities for back-end composting of biodegradable plastics also need policy leaning and support, for example, encouraging the construction of anaerobic digestion plants for the treatment of food waste and finally composting to make full use of the valuable organic matter that can be returned to the soil after digestion.

The utilization of biomass energy from composting of biodegradable plastics also needs to be supported by the establishment of scientific treatment systems (including facilities/control/certification methods) and waste separation regulations. For the development of degradable plastics in China, the current waste classification does not subdivide degradable and non-degradable plastics, leading to the final incineration of degradable plastics together with non-degradable plastics as dry waste, making the advantages of composting of degradable plastics for biomass energy also unavailable.

The European experience shows that compostable plastic is not a panacea, but it has its own unique value in disposable products that are difficult to recycle. Further improvement of the whole industry chain from upstream raw material manufacturing (using bio-based materials) to downstream treatment equipment and waste separation system is the real development future of compostable plastic.