Paper is used as a packaging material due to its natural degradability and sustainable properties. 2019 global paper and paperboard market is close to 425 million tons, compared to 250 million tons in the 90s. Currently, global consumption of packaging materials has increased significantly, and in some regions, the use of paper for packaging has been higher than plastic. However, its poor water resistance limits many of its applications, especially in food packaging, such as fresh fruits, vegetables, baked goods, fish and meat, which require water and moisture resistance and are still dominated by different disposable non-degradable plastics. Therefore, scientists have developed waterproof paper in the hope that this problem can be solved.

Recently, Maryam Naebe and others at Deakin University's Institute of Frontier Materials first prepared paper from the waste of banana trees (BP) and water hyacinth (WH), which are widely found in nature, and then coated the paper with ethyl cellulose (EC) to obtain waterproof and biodegradable paper and verify their performance in real-world packaging.

The related work was published in the Journal of Cleaner Production under the title "Utilisation of natural wastes: water-resistant translucent paper for food packaging".

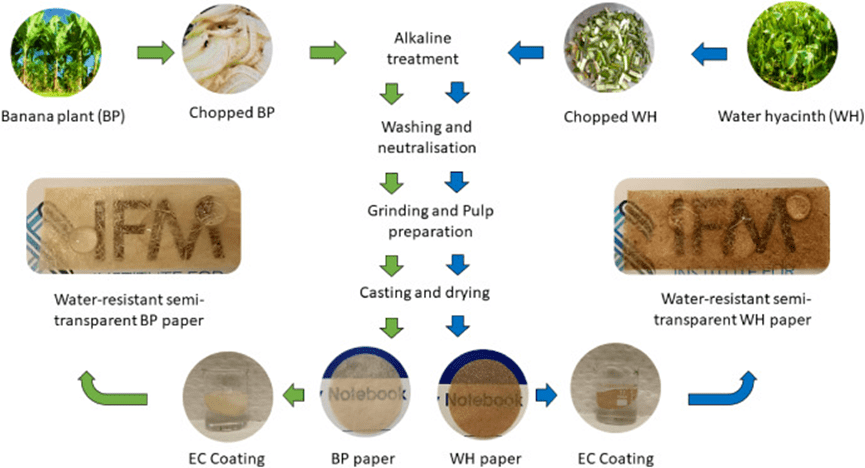

Preparation of waterproof paper

The two papers were prepared in a similar way. First the two plant wastes were first cut, treated with alkali, neutralized by water washing, and milled to make pulp and cast to dry to obtain the two papers. Subsequently, ethyl cellulose (EC) was applied to the surface of both papers by dip coating.

Preparation process of waterproof paper

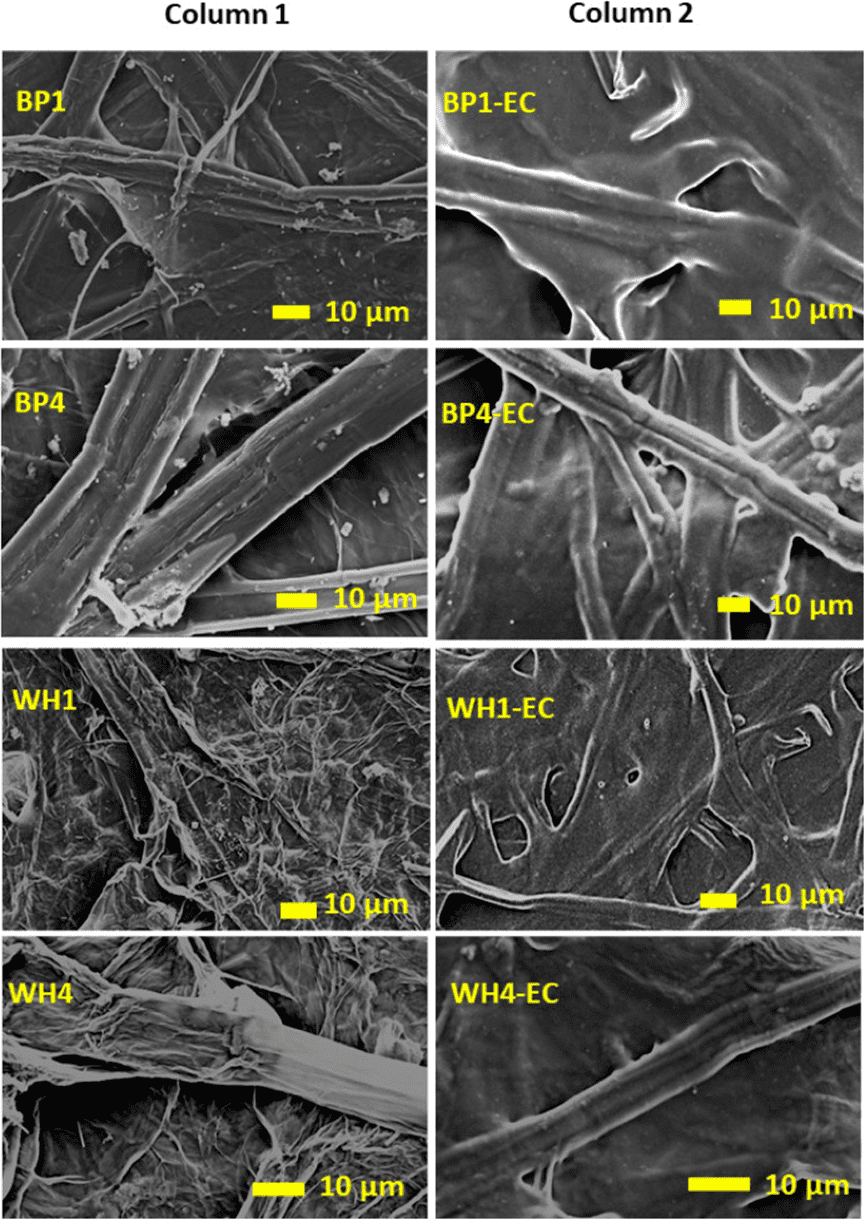

Surface shape of waterproof paper

The SEM images of BP and WH paper surfaces before and after EC coating are shown below. The paper produced by BP and WH contains larger particles in the form of fibers. These fibers are mostly around 10 μm wide and intertwined with each other, and BP4 shows a rougher surface than BP1. Similar observations were found in the WH samples, where WH4 showed a more pronounced roughness than WH1. A smoother surface was observed after EC coating on the corresponding paper surface, where the additional EC layer covered the paper surface and reduced the inhomogeneity caused by fiber aggregation.

Scanning electron microscopy (SEM) images (column 1): uncoated paper prepared from different concentrations (1 and 4 g) of banana plant (BP) and water hyacinth (WH); (column 2): corresponding paper surface after ethyl cellulose (EC) coating.

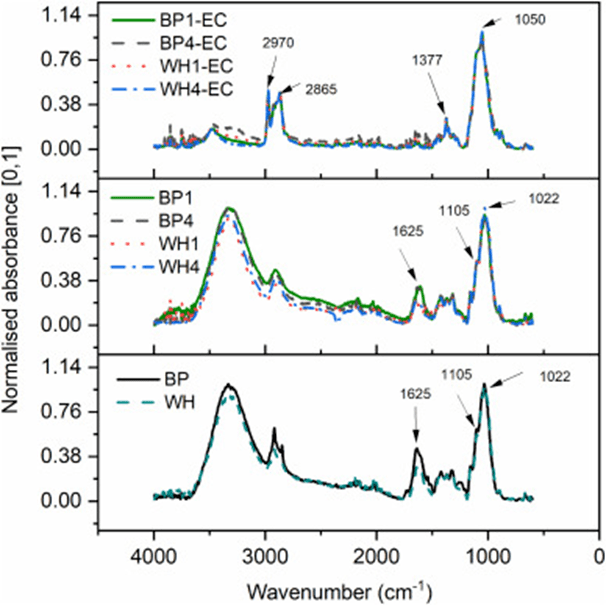

Chemical structure of waterproof paper

The FTIR spectra of the paper before and after BP, WH and EC coating are shown below. The raw BP and WH show a common lignocellulosic structure with a typical O-H stretching peak near the 3300-3350 cm-1 wave number. After BP and WH were prepared into paper, the positions and intensities of the peaks were similar to those of the raw materials, indicating that the chemical groups of cellulose, hemicellulose and lignin in BP and WH did not change significantly. All samples (BP1-EC, WH1-EC, BP4-EC, WH4-EC) after EC coating showed almost the same pattern, but different from the original and uncoated samples, probably because the thickness of the EC coating on the paper surface (about 10 μm) was larger than the penetration depth of ATR-FTIR and could not pass through the EC coating.

ATR-FTIR spectra of paper prepared with BP, WH and different amounts of BP and WH before and after ethyl cellulose (EC) coating.

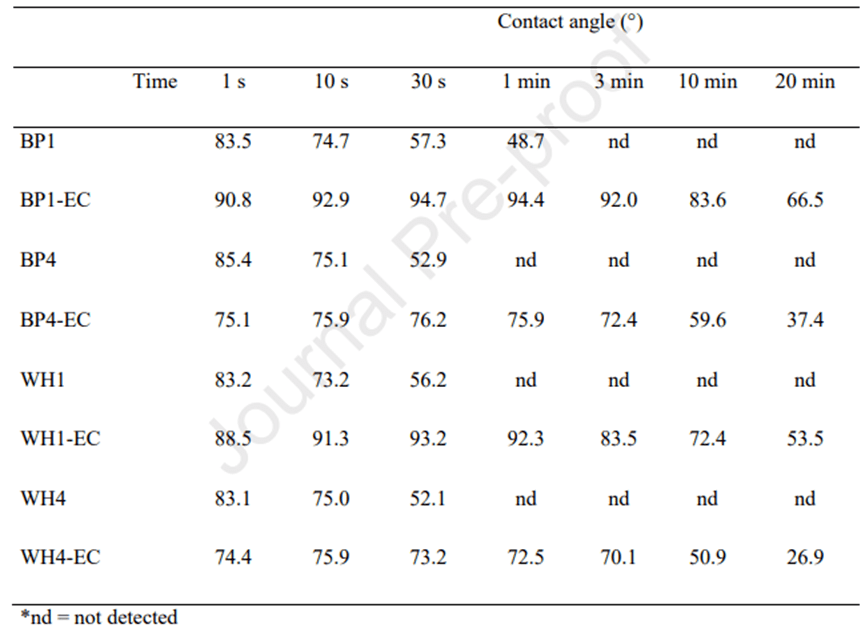

Contact angle of waterproof paper

The contact angles of water droplets on the surface of BP and WH paper are shown in the following table. BP paper shows greater water resistance than WH paper, which may be due to the higher crystallinity of BP (crystallinity index 61.7%). The trend of the contact angle after EC coating is very interesting, initially increasing with time, mainly in the first minute, and then slowly decreasing. This property was not seen in the uncoated samples, probably because they are more hydrophilic and do not have this surface resistance (EC coating) to water droplets. And EC coating can provide good water resistance during the lifetime of the paper (disposable packaging), but retain hydrophilicity (90° and lower) for microbial action during biodegradation.

Water contact angle of BP and WH at different concentrations (1 g and 4 g) before and after EC coating.

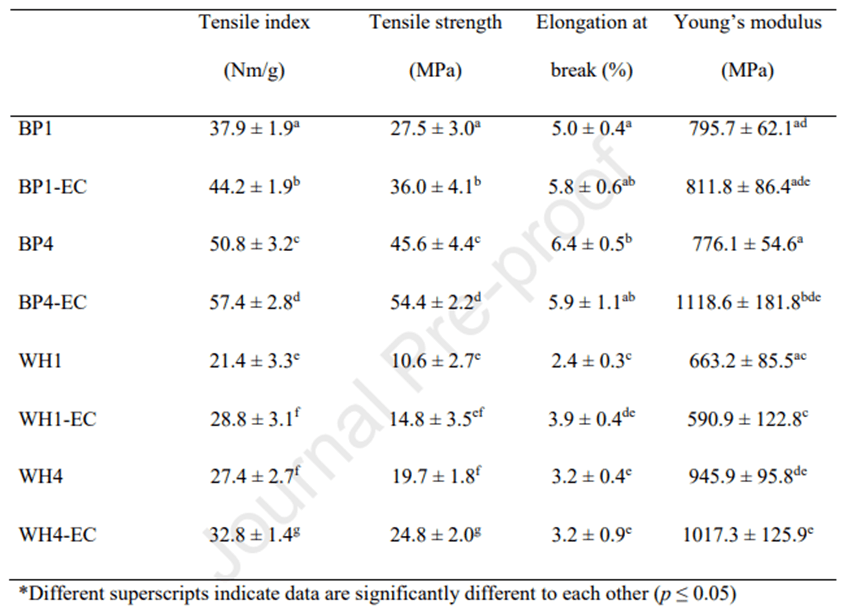

Mechanical properties of waterproof paper

Comparing BP and WH papers, the tensile index of BP samples is almost twice as high as that of WH samples. This may be due to the higher cellulose content and crystallinity of BP. After the EC coating was applied, the tensile index and tensile strength increased significantly for both BP and WH. The tensile indices of several papers obtained were comparable to those of commercially available A4 paper. There was no significant difference in Young's modulus between several paper samples, which were all around 590.9-1118.6 MPa. In addition, the changes in elongation at break were random and did not show any specific trend.

Tensile index, tensile strength, elongation at break and Young's modulus of paper with different concentrations (1 g and 4 g) of BP and WH and before and after EC coating.

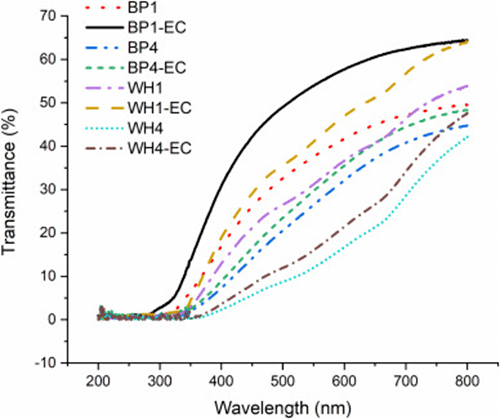

Light transmission of waterproof paper

The light transmittance of uncoated and coated paper samples is shown in the figure below. BP paper shows higher transmittance in visible wavelengths (400-700 nm) compared to WH, which may be related to the color and morphology of the sample. The EC coating increases the light transmission of the paper because, in addition to increasing the surface uniformity (as seen in SEM), the EC coating may also cover some chromophores of lignin on the paper surface, thus reducing light absorption. Since light absorption is the opposite phenomenon of light transmission, higher transmittance occurs in the coated samples. When higher amounts of BP or WH were used, the light transmission decreased. In the UV region (200-400 nm), the light transmission is close to zero in the UV-B (280-320 nm) and UV-C (200-280 nm) ranges, providing excellent UV resistance.

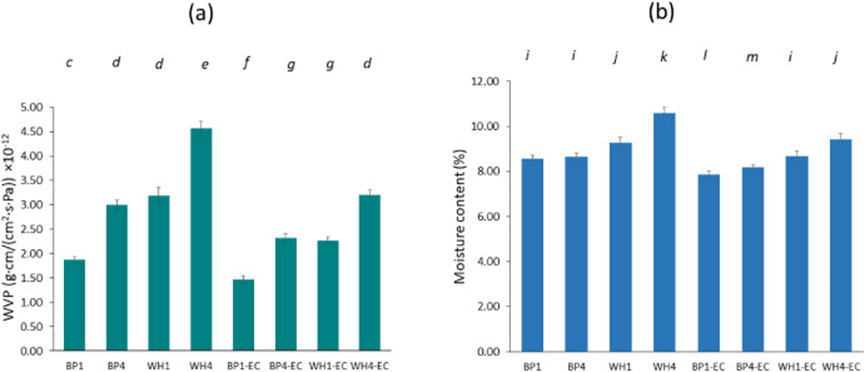

Water vapor permeability and moisture content of waterproof paper

The water vapor permeability (WVP) and moisture content (MC) of several paper samples are shown in Figure 5a and Figure 5b, respectively. It was observed that the WVP of the BP4 and WH4 samples was higher than that of BP1 and WH1. This may be related to the roughness caused by the presence of more fibers and their agglomeration on its surface. Both MC and WVP of the samples were reduced after the application of EC coating, which helps to limit microbial manipulation and is beneficial for food packaging. EC contains non-polar ether bonds (C-O-C), which have a lower interaction with water. As a result, the coating produces a more water-resistant surface, which is reflected in the results of all coated papers.

(a) water vapor permeability and (b) moisture content of paper coated with EC and uncoated prepared from BP and WH.

Summary

The paper is made from two resourceful natural waste resources, banana trees and water hyacinth, and no biomass residues are generated. The effect of coating on the physicochemical properties of paper was investigated by coating ethylcellulose on paper using the dip coating method. The coated samples exhibit significant water repellency properties. The ethylcellulose coating also imparted higher light transmission in the visible region as well as UV resistance. In addition, the tensile index of the paper increased after ethyl cellulose coating, and the elongation and Young's modulus remained unchanged. Overall, this bio-friendly paper can be used for food packaging, including fruits, vegetables, bread, fish and meat, as an alternative to non-biodegradable plastics.