According to media reports, we have seen many exciting developments in the field of eco-friendly plastics, which can be safely decomposed in the environment within a few years or even months. Although these materials are absolute green substitutes for petroleum-based plastics, scientists in New Zealand have come up with an innovative way to give them a "second life" and further improve their environmental qualifications.

This work was carried out at the University of Canterbury in New Zealand. The scientists used biodegradable tableware as a starting point, which is considered non-recyclable. These knives, forks, and spoons made of PLA bioplastics can be safely composted after use, but researchers have come up with a way to turn these materials into useful materials before they are thrown away forever.

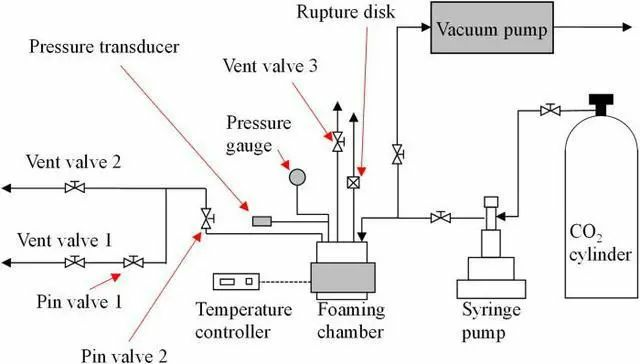

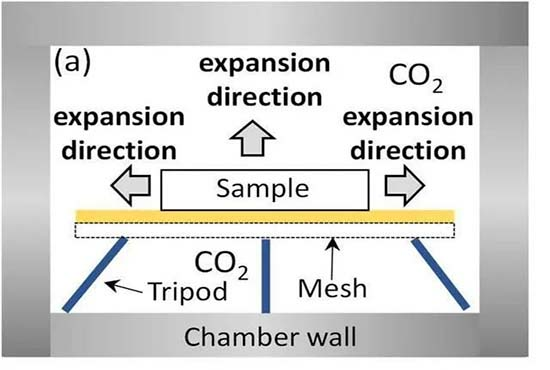

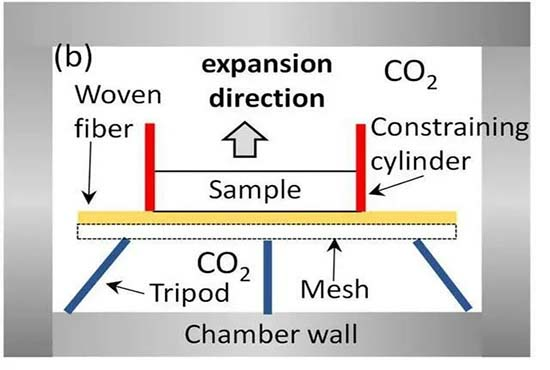

The team's breakthrough lies in an innovative process, that is, putting this tableware into a room full of carbon dioxide. Then, increase the pressure in the chamber to dissolve the carbon dioxide into the plastic. Then, when the pressure is suddenly released, the gas expands within the plastic and turns it into foam.

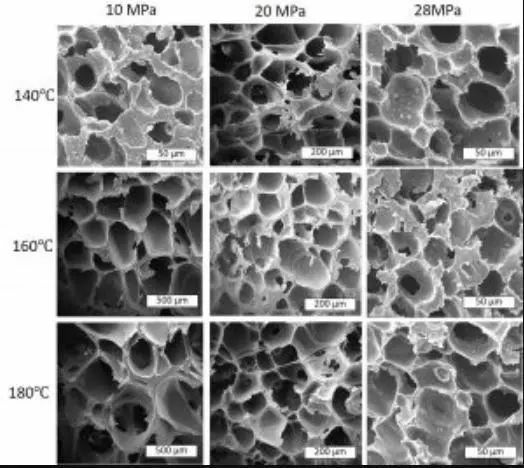

According to the team, this is a lot like the process of opening a can of soda and releasing carbonic acid. Interestingly, the scientists discovered that they can change the final product by adjusting the process. For example, the lower pressure in the chamber results in a larger volume of foam with a lot of air pockets.

Study author Heon Park said: "Adjust temperature and pressure, there is a window, we can make good foam. Not that every temperature or every pressure is effective. We have found that what temperature or what pressure can best make those plastics that cannot be foamed become foam. "

Scientists say that floating devices like buoys are a possible application for these bulky foams, while other versions of foam can enter the wall for insulation. For these recycled bioplastics, foam is a good ending, because in most cases, they do not need to provide great strength to achieve their goals.And this characteristic is usually affected in the plastic recycling process. And hopefully, scientists believe that the technology can be applied to a wider range of materials.

Park said: "We can extend foam applications to many plastics, not just this plastic."