Along with the rapid development of the economy, environmental awareness, China's ban on plastic in January 2021 to fully implement, as well as the European Commission guidelines for disposable plastic products, the upcoming revision of the Packaging and Packaging Waste Directive will be more favorable to include pulp molded plastic products packaging, including paper packaging of plant fiber base material, paper packaging has become the largest packaging materials used in food and beverage, food packaging and other areas.

1、 The disadvantages of PE laminated paper and silicone oil paper

Because of the contact with food containing oil, fat and water, paper packaging must be water, oil and permeation resistant. In order to obtain the effect of waterproof and oil-proof, most of the current food packaging paper is PE laminated paper, that is, a very thin layer of polyethylene plastic laminated on the paper, but also some water-based coating materials are polyacrylate, polyvinyl alcohol, carboxymethyl cellulose, etc., forming a continuous dense organic polymer film, so that oil and water can not pass through the protective layer, so as to achieve the purpose of waterproof and oil-proof. The high-end ones are also packaged with silicone paper, which has a three-layer structure: the first layer is the base paper, the second layer is the lamination, and the third layer is the silicone oil.

This type of polymer film itself is not resistant to oil, grease or can be spread on the surface of the coating, some contain bisphenol a grease, in contact with high-temperature food may release harmful substances, and this type of polymer materials can not be degraded in nature or degradation is very slow, recycling is difficult, high recycling costs, there are environmental pollution problems.

2、 The disadvantages of fluorine containing water and oil repellent

In addition to lamination, now more in the process of copying paper added into a very small amount of water and oil repellent or coated with a layer of water and oil repellent properties on the surface of the paper, reducing the surface tension of the paper, can give the paper substrate to water and oil repellent properties, and also does not affect the recycling of paper products. Although the water and oil repellent effect is excellent, but this type of water and oil repellent agent usually uses a long chain of perfluoroalkyl monomers (Perfluorinated compounds, PFCs), the number of carbon atoms greater than 6, usually 8 carbon atoms of C8-PFCs (containing 8 carbon perfluorocarbons), the longer the chain of carbon atoms in the perfluoroalkyl, the better its water and oil repellent performance, the better.

This is because the fluoropolymer can form a film on the paper fiber, and the long side chains containing fluorine in the film can be stretched and oriented at the interface, and the film can significantly reduce the surface energy of the substrate, which is smaller than the general liquid, so it has the performance of water and oil repellency.

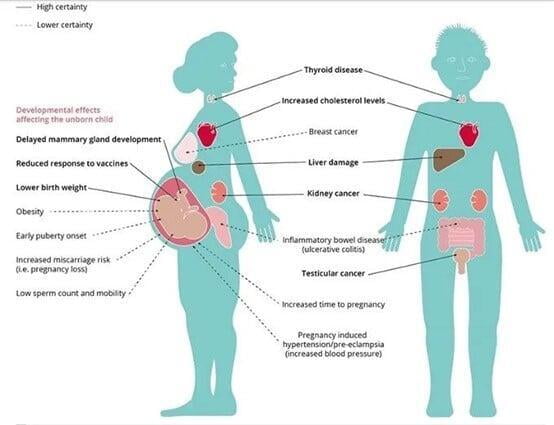

However, in recent years, it has been found through research that these long-chain fluoroalkyl compounds produce perfluorooctanoic acid ammonium/perfluorooctane sulfonates (PFOA/S) that are harmful to the environment and humans during use. Low doses of these substances are bioaccumulative, especially in long-term contact with food, and are highly toxic to humans and may cause genetic, reproductive, developmental, liver and cardiovascular diseases in organisms.

Therefore, the European Union, Canadian environmental organizations and the U.S. National Environmental Protection Agency have restricted the use of PFOA/S, long-chain fluoroalkyl compounds (carbon atoms greater than 6) are also restricted from being used in water and oil repellents for paper products, and C8-PFCs substances are gradually being withdrawn from the market.

3、 Fluorine-free water and oil repellent

In January 2015, the U.S. FDA issued a news release stating that food contact substances (FCSs) containing monoethanolamine and diethanolamine, valeric anhydride, and perfluoroalkyl substituted phosphate ester acids are prohibited as water and oil repellents for paper and paperboard used in contact with water and oil food.

In January 2021, the U.S. FDA announced that manufacturers would be required to voluntarily phase out the use of food contact packaging materials containing PFAS/PFOA within three years, with mandatory enforcement beginning in January 2024. As of July 2022, 26 U.S. states have introduced legislation to restrict the use of PFAS/PFOA, and 11 states have implemented it.

EU-wide restrictions on PFAS are gradually being expanded. In Denmark, a ban on the use of paper and paperboard-based food contact materials containing perfluorinated and polyfluoroalkyl compounds has come into full effect in July 2020. And the Netherlands, Germany, Norway, Denmark and Sweden intend to propose amendments to REACH regulations to fully restrict the manufacture and use of PFAS/PFOA.

Fluorine-free water and oil repellents have become a hot topic of research in the industry. It is safer and more environmentally friendly, and the paper packaging, pulp molding and paper mulch products produced with it are the first choice for export to Europe, the United States and Japan. Although it can achieve the same waterproof and oil-proof performance as fluorinated products through surface treatment such as coating and spraying, its high investment in equipment and processing costs make it impossible to be used on a large scale. The advantage of the fluorine-free water and oil repellent solution added to the pulp is that no investment in equipment is required and the cost is controllable, the disadvantage is that the oil repellent performance is not yet up to that of fluorine-based products. However, the industry also has different views on the testing of the oil-proof effect of fluorine-free additives. For example, the previous test standard of no penetration of hot oil at 95°C for pulp molded products for 30 minutes was considered by the industry and the end-consumer market to be significantly beyond the actual use scenario. At present, the European and American markets are more rational to accept the physical test results, or according to the end-use scenario and customer needs to choose a certain temperature (30 ℃, 40 ℃, 70 ℃) of hot oil 30 minutes without penetration test standards. After all, the solution that can be widely accepted by the market must be a practical and cost-controllable solution at the production end.