In order to expand the use of bioplastics in the field of durable goods, it is necessary to develop strategies that facilitate the biodegradation of bioplastics at the end of the product life, especially if the size and thickness of the bioplastics are increased, without compromising their mechanical properties during their service life.

Recently, in Germany, the SKZ Research Center, together with the RWTH Aachen University and Peiler&Klein Kunststofftechnik, conducted a study focusing on this topic.

The goal of this research is to accelerate the natural degradation of polylactic acid (PLA) by incorporating specific enzymes, such as proteinase K and keratinase ICCG, into manufactured products, and using zeolites that are “immobilized” by peptide adhesion enhancers for these enzymes.

However, what can be done to avoid the material starting to biodegrade during the lifetime of the artifact? The researchers explain that enzyme-loaded zeolites are converted into PLA zeolite masterbatch through a specially developed extrusion process.

These enzymes are introduced into the PLA matrix in an inert form and are only activated after a change in the environment and after the material wears out or melts; at which point they accelerate the PLA degradation process.

By targeting and modularizing the activation of enzymes, we hope to provide the industry with a solution that will allow companies to produce plastic products that are mechanically stable during use, as well as degrade more quickly and efficiently in the environment after the product's function has ended,” said Alexander Rusam, researcher and project manager at SKZ. ” The results of the initial tests conducted were promising.

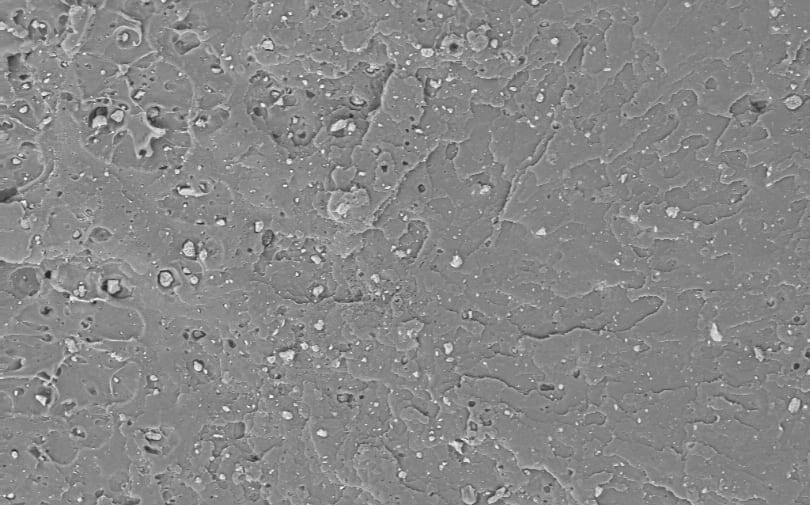

With the help of a microextruder, samples could be prepared in PLA and finely ground zeolite. The results of the analysis show that the porous material zeolite is very well distributed in the polymer matrix.

In addition, the researchers found that the addition of the enzyme did not adversely affect the mechanical properties of the PLA, which is a key goal in achieving industrialization of the product.

Rusam concludes, “These preliminary results demonstrate the feasibility of the process and open up attractive prospects for the development of plastics that are both functional and sustainable.”