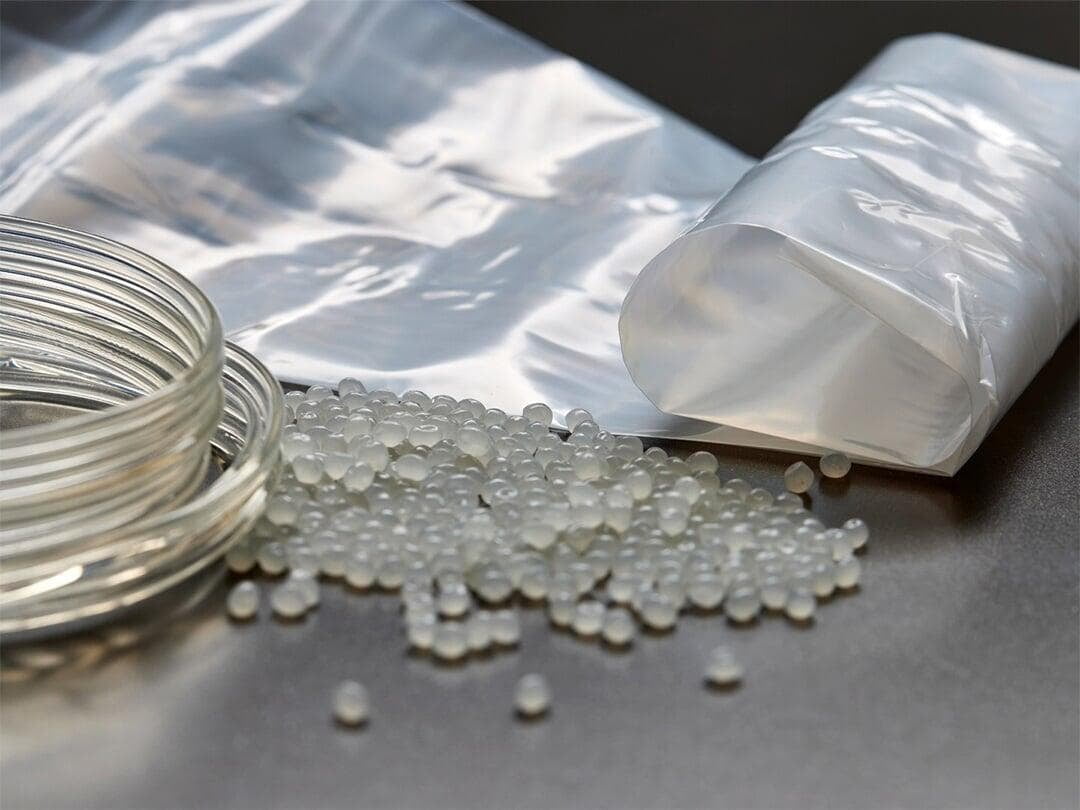

Typically, flexible disposable plastic films used for shopping or garbage bags are mainly made of petroleum-based low-density polyethylene (LDPE). However, these films come with a large carbon footprint and cause environmental pollution.

A team at the Fraunhofer Institute for Applied Polymer Research in Germany has developed a flexible recyclable plastic film material based on polylactic acid (PLA) bioplastics and paved the way for its commercialization.On June 12, 2024, they won the 2024 Joseph von Fraunhofer Prize for their efforts. They are Dr. Ben-jamín Rodríguez, Dr. Antje Lieske, and André Gomoll (see below).

LDPE is not biodegradable and can only be recycled mechanically with some loss of properties. PLA, on the other hand, is bio-based and biodegradable and can be chemically recycled into new plastics with relatively little energy input. However, because of its high brittleness, it is not suitable for use in its conventional form for the production of flexible single-use packaging, such as shopping bags or garbage bags, which are a major source of single-use plastic waste. In addition, PLA can only be produced profitably in continuous, large-scale plants, which to date have excluded smaller companies from being manufacturers.

"We combine plasticizers (so-called polyethers) directly with the polymer chains to make the material more flexible in the long term. Polyethers are non-toxic and can be bought from the market or produced from bio-based feedstocks. Until now, plasticizers have been blended into PLA as additives. However, over time, plasticizer molecules can migrate out of the material and make PLA hard again. To prevent this migration, we immobilized polyethers onto the polymer. To achieve this, we synthesized PLA-based block copolymers in which the ends of the polyether chain segments are covalently linked to the PLA chain segments." Dr. Ben-jamín Rodríguez explains.

The new material contains an "anchoring" plasticizer, which means that PLA will not become stiff over time.

Sustainable Flexible Plastics with Great Potential

They have developed a new flexible PLA material that contains no migratory plasticizers and, unlike LDPE, is at least 80 percent bio-based. "In the long run, we may be able to increase that percentage to almost 100 percent." Gomoll explains.

"In addition, our materials can be produced cost-effectively from commercially available raw materials through a simple synthesis process. This process does not require a large-scale synthesis plant, but can be implemented locally by medium-sized companies as a continuously operating process.

Until now, PLA could only be profitably produced in successive large-scale plants that excluded smaller companies from being manufacturers. Finally, this new PLA material can also be processed into plastic film using conventional processing equipment in a manner similar to LDPE - and it can be chemically recycled with much less energy input than LDPE."

These unique material properties have led the Polymer-Group company to commercialize the material.In 2023, Polymer-Group's subsidiary, SoBiCo GmbH, commissioned a plant for the production of a new PLA block copolymer in Pferdsfeld (western Germany). The company produces 2,000 tons per year of the new bioplastic called Plactid. In the long term, it will produce 10,000 tons per year of the new flexible PLA material.

This new bioplastic will make an important contribution to improving the sustainability of plastic packaging materials. In addition to flexible packaging films, this new material may also find its way into completely new application areas, such as the automotive industry, the textile industry and additive manufacturing.