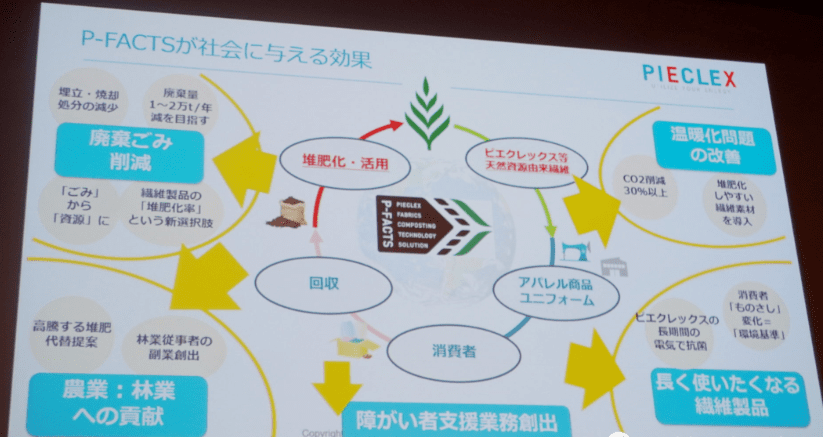

On October 12, PIECLEX, a fiber manufacturer jointly funded by Japan's Murata Manufacturing and Teijin Frito-Lay, released a news release stating that it will start a demonstration trial of recycling the company's fiber-based apparel products for use as compost in agriculture and forestry, P-FACTS (PIECLEX FAbrics Composting Technology Solutions).

PIECLEX is a material made from plant-derived polylactic acid (PLA), which has the ability to convert the energy generated by human movement into a weak electrical charge that produces an antimicrobial effect. The company has been supplying textiles for long term use to apparel manufacturers and is engaged in the manufacture and sale of T-shirts, towels, socks, etc. for commercial use under its own program.

"More than 500,000 tons of apparel products are discarded in the country every year, and I hope that this issue will be brought to the attention of society," said PIECLEX President Daichi Tamakura at a press conference in Tokyo.

Specifically, our current goal is to reduce 10,000 to 20,000 tons of clothing waste per year through composting and to reduce landfill/incineration. Using PIECLEX to collect garments also creates employment opportunities for people with disabilities by partnering with organizations that support them.

It is expected that compost garments made from the fiber will be used by agricultural and forestry workers to grow crops. In addition, because PIECLEX is made from a natural resource, polylactic acid, carbon dioxide emissions from the production process can be reduced by more than 30% compared to fibers made from petroleum-based materials.