Biology and chemistry are a key part of every global industry - from agriculture, cooking and food production to personal care products and consumer packaging. These industries excel at selecting and deploying efficient microorganisms to produce chemicals that produce results.

Biopolymers

Bio-based polymers are materials produced from renewable resources. The terms bio-based and biodegradable polymers are widely used in the literature, but there are key differences between them. Biodegradable polymers are materials whose physical and chemical properties deteriorate and eventually degrade completely when exposed to microorganisms, aerobic and anaerobic processes or hydrolysis. Bio-based polymers can be degradable (e.g., polylactic acid) or non-degradable (e.g., biopolysulfide). Similarly, while many bio-based polymers are biodegradable (e.g., starch and polyhydroxyalkanoates), not all biodegradable polymers are bio-based (e.g., polycaprolactones).

Bio-based polymers are receiving increasing attention due to environmental concerns and the recognition that global oil resources are finite and that more renewable, sustainable materials must be identified. Bio-based polymers not only replace existing polymers in a variety of applications, but also offer new combinations of properties that open up new applications.

Bio-based polymers are typically produced by three methods: 1) extraction and isolation from agricultural resources, 2) fermentation processes and 3) conventional synthesis using building blocks from renewable resources including lignocellulosic biomass, fatty acids and organic waste. Some bio-based polymers, such as proteins, nucleic acids and polysaccharides, are naturally occurring.

One of the more commercially attractive bio-based polymers is polylactic acid (PLA). Although it was discovered in 1845, PLA was not commercialized until the early 1990s. Its unique and attractive properties include good clarity, glossy appearance, high rigidity and resistance to a wide range of processing conditions.

PLA is widely used in food packaging, including food trays, water bottles, candy wrappers and tea bags. More recently, it has been used as a membrane material in the automotive and chemical industries. In its oilfield incarnation, the polymer is found in fluid loss control and fluid transfer agents, frac sand and proppant carriers, filter cake removers and degradable objects.

Like PLA, polyhydroxyalkanoates (PHAs), a family of polyesters produced by bacterial fermentation, have migrated to oil fields. PHA is naturally present in a variety of organisms. The most efficient producers can be isolated and fermented commercially to maximize the quality and yield of PHA.

Polyhydroxybutyrate is the simplest PHA, discovered by Maurice Lemoigne in 1926, and is a component of Bacillus megaterium.

Additional PHA monomers have since been identified, and this diversity allows for the production of a wide range of bio-based polymers with a variety of properties tailored to specific applications.

PHA has thermal and mechanical properties similar to those of polystyrene and polypropylene. As a result, PHA is suitable for a wide range of food and medical packaging applications, as well as disposable items such as hot cup lids, forks, spoons, knives and cosmetics. PHAs and their copolymers are widely used as biomedical implant materials and drug delivery systems. In the petroleum industry, PHAs are used to remove filter cake, as internal crushers to reduce the viscosity of completion fluids, and to encapsulate chemical additives used in controlled chemical release applications.

Bio-solvent

Solvents are an important part of many chemical processes and products. They are used in a variety of industrial applications, including agrochemicals, paints and coatings, household and industrial cleaners, and pharmaceuticals. Today, consumers can choose solvents based not only on their physical properties, but also on their impact on the environment. Many consumers prefer environmentally friendly solvents or green alternatives to traditional products. In this new era, bio-solvents are becoming more widely available because they combine environmentally friendly properties with low cost.

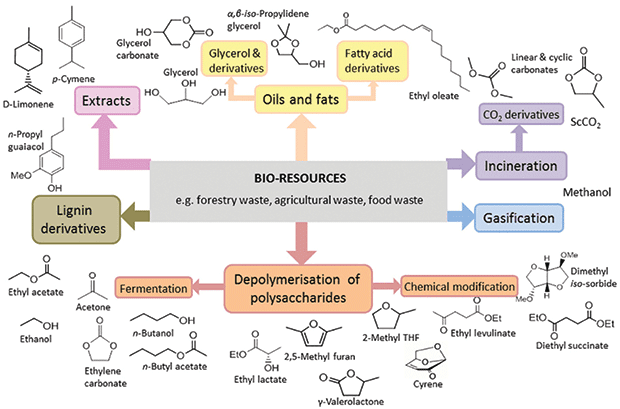

Figure 1 Example of bio-derived solvent

For a solvent to be considered a green solvent, it must meet several criteria. It should be bio-based, free of volatile organic compounds, non-toxic, biodegradable and recyclable. Green solvents can include a wide range of products (Figure 1), especially bio-based ethanol, D-limonene, dipentene and soy acid methyl ester.

While the market share of soy acid methyl ester (soy fatty acid methyl ester) is rapidly increasing, many manufacturers currently prefer bio-based ethanol because its widespread commercialization makes it more affordable and easier to purchase. It helps bio-based ethanol to be suitable for a wide range of applications. Ethyl lactate is another increasingly popular green solvent, mainly as an alternative to petroleum solvents.

Circa Group, a company that provides solutions for converting waste biomass into advanced biochemical materials, recently introduced Cyrene, a bio-based dipolar non-protonic solvent that provides an alternative to petroleum-derived dimethylformamide and N-methyl-2-pyrrolidone products. These products are used in the production of pharmaceuticals, pigments, paint strippers and adhesives.

One of the more exciting use cases for green solvents is dry cleaning. Traditional dry cleaning solvents produce harmful waste, including carbon, dyes, grease and various filter materials. But thanks to Green Biologics, dry cleaners can now use bio-based solvents (methylene dibutyl ether) made from corn. Called SOLVONK4, it cleans better than conventional solvents, does not harm the environment and minimizes health-related problems. In addition, it is the first and only bio-based solvent for dry cleaning.

Various bio-solvents, including D-limonene, dipentene, lactate and fatty acid esters, have been used in the oilfield to improve the efficiency of oil-based drilling muds as well as remediation and production-enhancing fluid systems. This fluid system helps to remove pipeline deposits, repair paraffin and asphaltene deposits and clean storage tanks.

Bio-based fluids have been used in the formulation and delivery of products for the production of chemicals and for drilling and completion applications. For example, they are often paired with surfactants to obtain microemulsions for rejection aids and to enhance oil recovery from conventional and unconventional reservoirs.