On Feb. 1, Korean scientists developed an environmentally friendly paper straw that is 100% biodegradable and does not get wet, which not only outperforms traditional paper straws but can also be mass-produced at low cost. The research was published in the latest issue of the journal Advanced Science.

The discovery came from the joint research group of Dr. Oh Dongyeop and Dr. Kwak Hojung of the Korea Research Institute of Chemical Technology (KRICT) and Professor Park Jeyoung of Seogang University in Seoul, Korea.

The most common coating material for paper straws and cups is polyethylene or acrylic resin, but this hybrid material is made of paper and plastic, making it difficult to recycle, and the polyethylene coating breaks down into microplastics. In addition, traditional paper straws get wet after prolonged contact with liquids, making them inconvenient to use. Polylactic acid straws and straw straws are alternatives to paper straws, but the former cannot be decomposed in the ocean; the latter, although easily decomposed, is difficult to produce on a large scale.

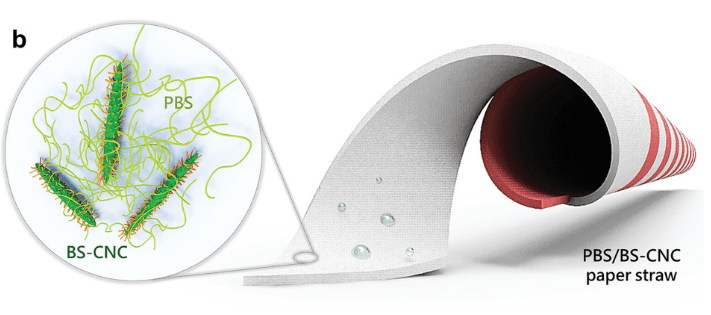

The new paper straws rely on a well-known biodegradable plastic, polybutylene succinate (PBS), to which the team added a small amount of cellulose nanocrystals (CNC) to create the coating material. In the simplest terms, cellulose is plant fiber. Since the added cellulose nanocrystals are the same material as the main component of the paper, they provide optimal adhesion of the PBS to the paper surface during the coating process.

Schematic diagram of PBS/BS-CNC paper pipette

The new paper straw not only prevents foaming when used for soft drinks because of its uniform and seamless surface coating, but is also highly waterproof and tough because of its watertight surface. In aerobic composting and in the marine environment, all degradable components are effectively broken down. This technology contributes to the achievement of the United Nations Sustainable Development Goal 14 (living underwater).

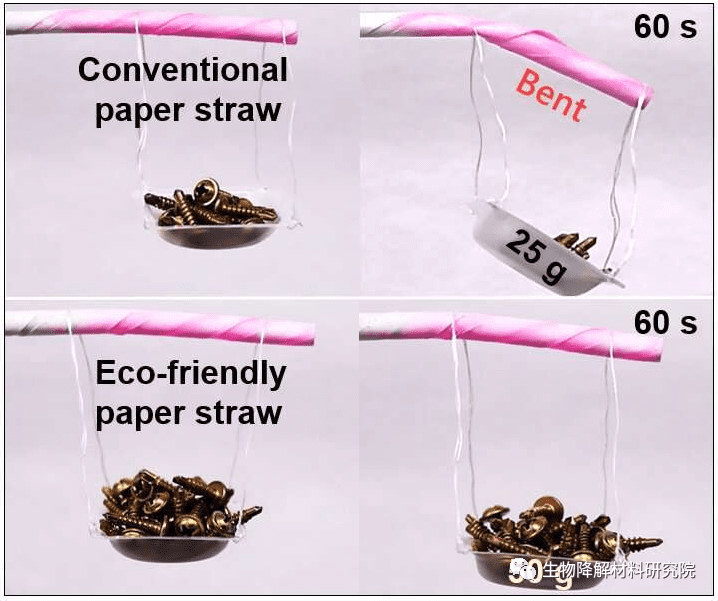

Research has found that the new paper straws stay intact in both cold and hot beverages. When used to stir beverages such as water, tea and milk, or when in contact with liquids for long periods of time, the straws do not become wet. Traditional paper straws will bend severely when they weigh 25 grams after being immersed in cold water at 5℃ for 1 minute. However, under the same conditions, the new paper straws will not bend even if the weight exceeds 50 grams.

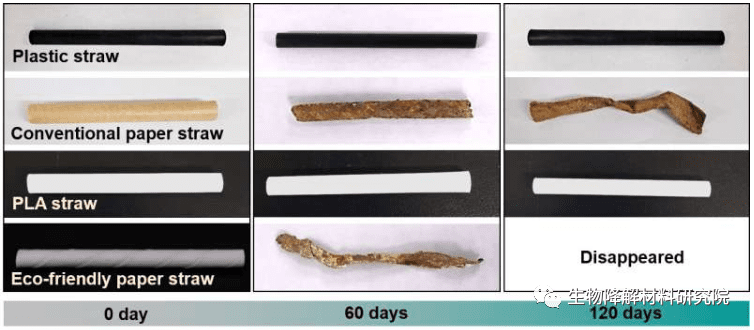

Traditional disposable straws are particularly bad in the marine environment because of the damage they cause to marine animals. But the new straws also break down well in the ocean. It was found that the total weight of ordinary plastic straws and PLA straws was only reduced by 5% when they were immersed in seawater for 120 days; while the new straws were reduced by more than 50% after being immersed in seawater for 60 days, and completely decomposed after 120 days.

Technical points

Due to the difference in hydrophilicity and polarity, CNC tends to aggregate in the PBS matrix, which limits the nucleation and enhancement effect of CNC. To overcome this limitation, the CNC surface was modified with PBS oligomers in a two-step esterification process. The hydroxyl groups of CNC were first modified with succinic anhydride (SA) using ring-opening chemistry (to obtain SA-CNC), followed by successive esterification with 1,4-butanediol (BD) at 180 °

BS-CNC is regularly dispersed in the PBS matrix, which helps to increase the physical strength of PBS by reducing its average spherical crystal size. In addition, its modified groups enhance water stability for long-term application in various beverages. In addition, it appears to overcome the drawbacks associated with alternative straws (e.g., greased paper and PLA straws) and other biopolymers used in the manufacture of various disposable products.PBS/BS-CNC straws represent a new and groundbreaking bioplastic discovery.