PLA (polylactic acid) is derived from bio-based renewable resources. After use, it can be degraded into carbon dioxide and water by composting. It has no pollution to the environment and is a kind of biodegradable plastic with great application prospects.

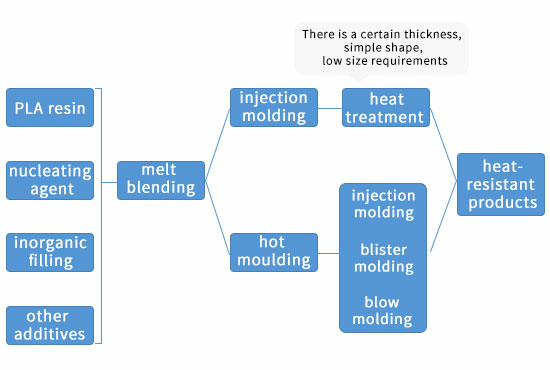

However, due to the slow crystallization rate of PLA, the crystallization cannot be completed during the processing and molding process, resulting in poor heat resistance of the product. The commonly used methods to improve PLA crystallization are adding nucleating agents, crystallization accelerators and optimizing processing technology. The more commonly used PLA crystallization nucleating agents are talc, montmorillonite, aliphatic amide hydrazide compounds and organophosphate metal salts.

Rui et al. studied the crystallization behavior of PLLA/PDLA mixtures and showed that a composite stereosome formed during cold crystallization of PLA mixtures can increase the crystallinity of PLLA and the temperature range of cold crystallization. In addition, mold temperature, annealing process, etc. also have a great influence on PLA crystallization.

Inorganic nucleating agents include silica and lamellar fillers (montmorillonite) in addition to talc. Organically modified montmorillonite not only has a nucleating effect, but also has a plasticizing effect; Amides and benzoic acids belong to organic nucleating agents, which have better nucleation effects, and metal phosphates have better nucleation effects. For example, 4,6-di-tert-butylphenyl sodium phosphate or 2,2-methylene bis(4,6-di-tert-butylphenyl) phosphate sodium salt.

PLA crystallization accelerators that act synergistically with nucleating agents mainly include higher fatty acid esters, fatty amides, such as erucamide, stearamide, oleamide, ethylenebisstearylamide, ethylenebisoleamide, ethylenebislauroamide, phthalamide, etc. Some of these compounds also have toughening, plasticizing and demoulding effects, and can improve the surface gloss of products.

One of them or a combination of two or more can be selected when used.

Whether the use of nucleating agent and inorganic filler at the same time affects crystallization depends on the type of inorganic filler material, and it has a promoting effect on crystallization. For example, talc powder; if adding fillers without nucleation effect, the crystallization effect will usually be reduced, because too much inorganic filler will hinder the movement of molecular segments and will reduce the crystallization effect.

The heat resistance and transparency of polylactic acid is a requirement put forward by the current consumer habits. The preparation of heat-resistant transparent polylactic acid mainly requires that the size of the formed spherulites is lower than the wavelength of visible light, which requires coordination in the nucleating agent and the molding process. The addition of nucleating agent will make PLA achieve a relatively high crystallinity, while controlling the size of the spherulites to be lower than the wavelength of visible light, so that visible light can pass through, making the material heat-resistant and transparent.

Polylactic acid crystallization has a greater impact on its own mechanical properties, and the relationship between PLA crystallization and mechanical properties mainly depends on the control of the degree of crystallization. When the crystal grains are very small and the distribution is very uniform, the mechanical properties of the material are improved. If the crystal grains are controlled very small, the toughness is increased. After polylactic acid is annealed, the impact strength increases, which is a phenomenon worthy of attention. Generally speaking, after PLA is crystallized, especially when large-sized spherulites are formed, the bending strength will increase.

PLA cold mold injection, because its crystallinity is very low, so the product is transparent. If the products produced from the cold mold are heated in a drying tunnel and treated at 110 or 120°C for a period of time, large-size spherulites will be produced, making PLA become opaque. Polylactic acid has the shortest half crystallization time at 110-120°C. This is just a theory. However, there is a certain gap between reality and theory, and specific tests must be made according to different products.