The consumer wipes market is booming. From hand washing to surface disinfection to bathroom hygiene, consumers are relying on wipes more than ever before, and manufacturers are taking notice. According to Smithers, the wipes market consumed 1.4 million tons of nonwovens in 2020, and its market value reached $19.6 billion.

The annual growth rate from 2015-2020 is reported to be 7.9%. This spiked during the New Crown outbreak when market demand for wipes increased. Even after demand peaked in the second quarter of 2020, sales of certain categories of wipes were still more than 20% higher than before the outbreak.

More consumers than ever before are using wet wipes, driving growth in this market. According to recent surveys, there has been a 30% increase in the number of people using wipes regularly compared to 2008. In addition, the number of people using surface disinfecting wipes is up 44% from the start of the new crown epidemic, and this behavior is expected to continue.

Most wipes manufacturers and their suppliers are looking to increase investments to meet this growing demand. Two of the industry's largest wipes processors, Nice-Pak and Rockline Industries, announced investments in the U.S., primarily in the production of surface disinfecting wipes, while disinfecting wipes leader Clorox added a new production line in Atlanta, Georgia, and expanded its network of contract manufacturers located in the U.S. and globally.

Bio-based environmental transition for brand owners

As the use of wipes continues to climb, the industry is facing the challenge of making products greener. This is being driven not only by regulations such as the European Single-Use Plastics Directive and similar measures being evaluated in several U.S. states, but also by consumer preference for more natural products.

Pricie Hanna, managing partner of Price Hanna Consultants, is also seeing more direct-to-consumer brands competing for consumers who value sustainability. "Millennials and younger consumers are driving this trend at the same time that the public is increasingly concerned about sustainability," she explains. "In addition to direct-to-consumer brands, we are seeing major manufacturers and their brands adopt similar strategies in the baby and feminine care categories. "

Kimberly Launches Natural Fiber Wipes

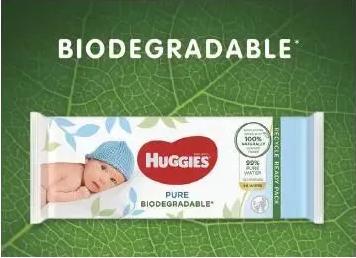

Earlier this year, Kimberly-Clark (Kimberly-Clark) launched a new line of Huggies Pure Biodegradable wipes in the UK that are biodegradable after 15 days in simulated landfill conditions.

Huggies said the plastic-free wipes are made from 100 percent natural fibers. Independent tests have shown it to be biodegradable after 15 days in simulated landfill conditions, making it the brand's first biodegradable product. The brand has pledged to completely eliminate plastic from its line of baby wipes in the U.K. within five years or sooner.

In addition to launching its first biodegradable products, Huggies has made significant progress toward other goals of its "footprint minimization" mission. Achievements to date include removing 359 tons of plastic from its baby wipes portfolio each year, removing 17 tons of plastic from the Huggies Extra Care portfolio each year, and removing the internal plastic bags from its larger boxes, saving 43 tons of plastic each year.

"We know this will be welcome news for parents who rely on wipes as a daily parenting necessity but are also working to reduce their impact on the planet," said Ori Ben Shai, vice president and managing director of Kimberly-Clark UK and Ireland, "No parent should not have to compromise between caring for their children and protecting the environment, so we are proud to be able to offer an affordable and sustainable solution with baby's skin care at its core."

Unicharm launches biodegradable wipes

"The launch of our first biodegradable product brings us one step closer to achieving our goal of a 'footprint minimization' mission. We know we have a long way to go to achieve this ambitious plan, but we are committed to developing the best products to meet the evolving needs of consumers."

Similarly, Unicharm will launch Mamy Poko Premium baby wipes. The new product uses organic cotton composites that have received the world's highest safety standard "OEKO-TEX" STANDARD100 certification, as well as "FSC certification", which proves that it takes into account both safety and environmental aspects.

The "OEKO-TEX" STANDARD100 is an international safety certification granted only to textiles that have been analysed and tested to a strict standard by the OEKO-TEX® International Community Certification Inspection Unit for more than 350 hazardous chemical substances. In order to obtain this certification label, all materials and chemicals used in the product must specify their experimental criteria. In other words, products bearing this label are "certified" as having high safety standards.

Unicharm is working hard to protect a better future for babies, and their commitment to providing safe and reliable products is evidenced by the ORGABITS program, an earth-friendly and sustainable activity.

In May, baby care brand Coterie launched a wipe made from 100% plant-based biodegradable and compostable materials. Designed in collaboration with Veocel Brands, Coterie wipes contain 99 percent water and are the most sustainable baby wipes on the U.S. market.

Recent certification tests have shown that Coterie wipes are proven to be fully compostable after only a few weeks, decomposing even under the harshest conditions, compared to similar wipes that take hundreds of years. By comparison, acceptable standards for compostable products can take up to six months, while plastic-based products, can take hundreds of years. In addition, the new wipes are the first in the country to receive chemical safety certification from the Environmental Working Group (EWG), mildness certification from the National Eczema Association and sustainability certification from TÜV-OK Compost HOME.

Bio-based transformation for nonwoven manufacturers

Suominen

In terms of substrates, the nonwovens producer serving the global wipes market continues to focus on developing alternative sustainable materials. Nonwovens supplier Suominen has set a goal to increase sales of sustainable materials by 50 percent and to launch more than a dozen sustainable products each year. 2020 saw the company launch nine sustainable products and grow sales by 22.5 percent.

"Sustainability is increasingly important to our customers and other stakeholders," said Lynda Kelly, senior vice president of business development, "and we help our customers achieve their own by providing them with products made from renewable, recyclable, compostable and plastic-free raw materials. environmental goals by providing our customers with products made from renewable, recyclable, compostable and plastic-free raw materials. As a result, we're bringing more sustainable options to this market."

In sync with this strategy, Suominen has launched products such as Biolace Pure, a 100% plant-based product with excellent cleaning power. The successful development of this innovative material with outstanding liquid management and cleaning properties is based on Suominen's long history and expertise.

Another sustainable household product from the company is Biolace Bamboo, which also offers superior cleaning capabilities. As the name suggests, Biolace Bamboo's main ingredient is bamboo, a perennial grass that is one of the fastest growing plants in the world. Its high rate of regrowth makes it an important alternative.

"Compared to traditional petrochemical-based nonwovens used in wipes, Biolace Pure and Biolace Bamboo offer significant advantages in terms of reduced CO2 footprint and lower environmental impact," Kelly added.

Biolace Ultrasoft, meanwhile, is a nonwoven for personal care and baby products made from plant-based, biodegradable, plastic-free and compostable raw materials. The latest addition to Suominen's sustainable portfolio, it is also a continuation of its Biolace product line, which was launched more than a decade ago.

Biolace Ultrasoft was developed to meet the needs and quality expectations of its customers and consumers for sustainable products. According to Suominen's tests, the structure and composition of Biolace Ultrasoft nonwovens offer a 25% improvement in cleaning efficiency compared to 100% viscose spunlace nonwovens of the same basis weight, and a 38% improvement compared to polyester wipes.

"Biolace Ultrasoft is a sustainable product with outstanding cleaning efficiency and exceptional softness. It is the perfect solution for baby and personal care products, such as make-up wipes and baby wipes. The softness makes it suitable for gentle skin products as well," said Johanna Sirén, the company's category management manager.

Jacob Holm

At the same time, Jacob Holm has introduced a new sustainable member to his Sontara EC family in EMEA.Sontara EC Green is a unique new high performance 100% cellulose based product made from proprietary Sontara technology. This ultra-pure manufacturing process produces a 100% bio-based product that contains no binders, chemicals or silicones.

Sontara EC Green is patented and produced from renewable resources, making it an excellent alternative to non-biodegradable substrates. The wipes come in an easy-to-dispense box with sealed packaging to prevent any contamination. With this product, users can get the critical cleaning power they need while being environmentally responsible.

In addition to new sustainable packaging made from recycled materials and a new folding format, Jacob Holm has added sustainable options to its Sontara EC product line. This takes Jacob Holm's commitment to sustainability and continuous innovation one step further.

The development of more sustainable materials is a key component of Jacob Holm's Project Boost, a multimillion-dollar global expansion program that will increase its global production capacity.

"Project Boost will help us increase capacity to serve our global partners and provide them with more sustainable substrate options, as well as continue our position as a leader in nonwovens innovation." said Martin Mikkelsen, the company's chief executive officer.

Glatfelter

As a manufacturer of air-webbed nonwovens, Glatfelter has 30 wipe substrates that contain a high percentage of recycled materials and wood pulp.

For the disinfecting wipes market, Glatfelter now offers an environmentally friendly cellulose-based air-flow webbed nonwoven substrate for GlatClean disinfecting wipes.

"Glatfelter is committed to providing our customers with wipe substrates that meet extremely high standards of hygiene, safety and sustainability," said Chris Astley, senior vice president and chief commercial officer of the company, "and we are proud to bring to the cleaning and disinfecting wipes market by bringing an environmentally friendly air-flow web formation solution with a cellulosic substrate."