Recently, styrene company Ineos Styrolution developed a food-grade packaging film called K-Resin DK11, which it claims is the material of choice for controlled atmosphere packaging (CAP) film applications. K-Resin DK11 combines "excellent" clarity, toughness and high breathability. In addition, the company emphasizes that the optimized styrene material for CAP film packaging is ideal for extending the shelf life of perishable items and meeting food contact regulations.

CAP materials can extend the shelf life of perishable items and meet food contact requirements

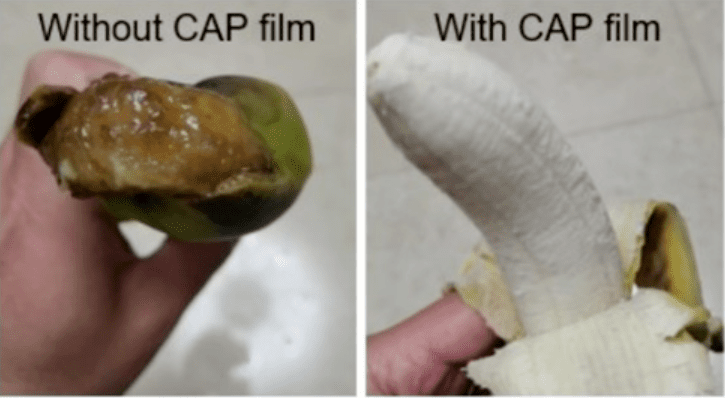

Ineos Styrolution said K-Resin DK11 has proven to be an ideal material for banana growers in China, who have been looking for an environmentally friendly packaging solution that would allow for controlled ripening during the transportation of bananas from Yunnan to other coastal areas of the country.

Packaging solutions are expected to maintain the freshness, color and integrity of the fruit. In addition, it is required that the fruit be allowed to ripen organically and that no preservatives or ripening agents be used during transport. K-Resin DK11 is easy to process and can be made into tough, high definition films. It combines good thermal stability with high breathability, making it ideal for CAP film packaging of fruits and vegetables while extending shelf life.

K-Resin is Ineos Styrolution's crystal clear thermoplastic styrene-butadiene copolymer (SBC), known for its unique sparkling clarity, impact toughness, stiffness and "extraordinary" gloss.

The company says the K-Resin range is an "excellent" choice of material for applications requiring food contact compliance due to its compliance with international food contact regulations.

For more than 40 years, it has been used in a wide range of applications, from packaging and toys to medical components and displays.

The film's breathability allows bananas to ripen organically while maintaining shelf life

Ineos Styrolution says its crystal clear thermoplastic SBC family, K-Resin, Styrolux and Styroflex, combine high clarity and impact resistance, making them suitable for applications in a variety of industries, including healthcare, packaging and toys. "The film's excellent breathability allows bananas to ripen organically while maintaining the fruit's shelf life, especially during long cross-town trips," commented Jary Liao, Director of Transparent Specialties Asia Pacific.

"As plastic food contact safety compliance regulations in China and globally become increasingly stringent, Inglis Styrolution is constantly updating, improving and differentiating our product portfolio and services to create more value and ensure fresh fruits and vegetables for the people of China and other countries."

On a related note, the Waste and Resources Action Plan claims to have proven that plastic packaging does not necessarily extend the life of fresh, uncut produce and actually increases food waste.

Other current research is focused on the development of bioplastic films for fresh produce. Scientists in Brazil and Portugal have developed an environmentally sustainable process to produce biodegradable plastics using pigments derived from yeast in a "green" solvent. In addition, researchers at North Carolina State University have converted leftover sawdust powder and agricultural residues into a polystyrene foam-like packaging material.