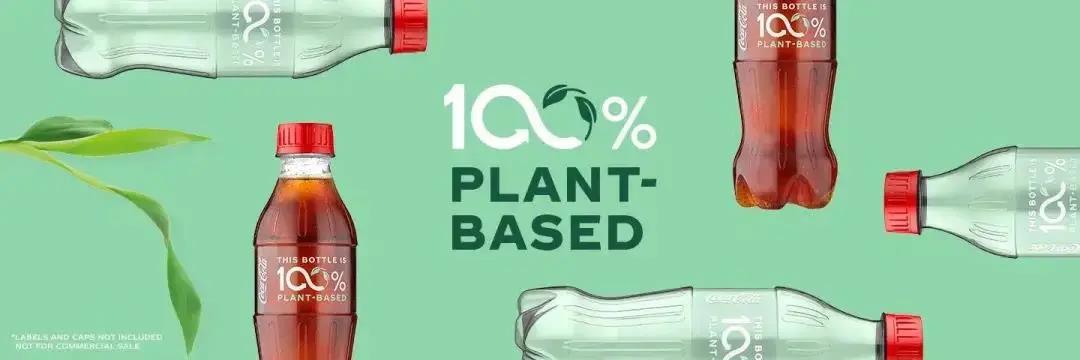

In October, Coca-Cola presented its first prototype bottle made from 100% plant-based plastic. Dana Breed, Coca-Cola's Global Director of Research and Development for Packaging and Sustainability, gave a special interview to the media detailing its innovative research and development process and its efforts to highlight the importance of Coca-Cola's broader sustainability efforts.

Q: What drove the creation of this bottle in the context of Coca-Cola's broader sustainability strategy?

A: As part of our vision of a world without waste, we are working to make all of our packaging more sustainable, including maximizing the use of recycled and plant-based renewable ingredients while minimizing the use of virgin oil-based materials. We are committed to recycling the equivalent of every bottle we sell by 2030, so none of our packaging becomes waste and old bottles are recycled into new bottles; making our packaging 100% recyclable; and ensuring that 50% of our packaging comes from recycled materials. This innovation supports the World Without Waste vision, particularly the recently announced goal of reducing 3 million tons of virgin plastics from petroleum sources by 2025.

Coca-Cola will achieve this 20 percent reduction by investing in new recycling technologies such as enhanced recycling, packaging improvements such as lightweighting, alternative business models such as refillable, dispensing and fountain systems, and the development of new renewable materials.

Q: Can you outline the R&D process that leads to the creation of a new solution?

A: Coca-Cola has been heavily involved in this area for many years. The R&D process includes paying close attention to new chemicals and processes that can be applied in this area, linking different aspects of them when it makes sense to do so, and guiding the development of areas where there is a gap between the state of the art and something that can be fully deployed.

For certain aspects of 100% plant-based bottles (excluding caps and labels), we are more hands-on, as evidenced by jointly owned patents, for example. We also engage with partners in other ways, such as working with the supply chain to develop specific capabilities. Finally, we leverage the internal capabilities we use in developing new packaging around the world.

Q: In 2009, Coca-Cola introduced a PET bottle made from up to 30 percent plant-based materials. What were some of the key lessons Coca-Cola learned from earlier iterations in terms of creating this new 100% plant-based bottle?

A: PET contains two molecules: approximately 30% monoethylene glycol (MEG) and 70% terephthalic acid (PTA). The original PlantBottle was launched in 2009 and included MEG from sugarcane, but PTA has always been a petroleum-based source.

Our new plant-based bottle prototype made from bio-based paraxylene (bio-PX) - using Virent's new process - has been converted to bio-based terephthalic acid (bio-PTA). As the first beverage packaging material produced with bio-PX at demonstration scale, this new technology marks a step change in the commercial viability of biomaterials. This bottle of bio-PX was produced from corn sugar.

The second breakthrough technology, jointly owned by Coca-Cola and Changchun Meihe Technology, simplifies the production process of bMEG.

Typically, bMEG (30% of the plant-based material in our existing PlantBottle) is produced by converting sugarcane or corn to bioethanol as an intermediate, which is subsequently converted to bio-based glycol. The challenge inherent in using bioethanol is that you are competing with fuel. Coca-Cola needed and co-developed a next-generation MEG solution that addressed this challenge, but also a solution that could use second-generation feedstocks, such as forestry waste or agricultural by-products. Our goal for plant-based PET is to minimize our carbon footprint, so the portfolio of commercialized technologies our partners bring to the table is well suited to this strategy.

100% plant-based PET plastic packaging bottles (except caps and labels)

Q: How does bPET compare to PET in terms of performance. What is the reason behind these differences/similarities?

A: bPET did not exhibit any unexpected drawbacks. The plant-based bottle was tested following the same comprehensive performance protocols we use for any commercial packaging, and it continues to meet or exceed these performance criteria.

Q: Let's talk about the end of life - how do bottles get recycled and how does this process compare to the recyclability of PET bottles?

A: Developing a renewable pathway for PET means that these materials will fit into existing infrastructure for recycling as soon as they are introduced. bPET is designed like PET, which is why it is part of our strategy. It can be alternatively blended with rPET and virgin fossil-based PET, including in the recycling stream.

Q: How do bottles (and bPET in general) compare to standard PET in terms of overall carbon emissions? Has any LCA been performed to assess this?

A: The current bottles are prototypes and therefore cannot be compared to bottles produced on a large commercial scale (e.g. PET). It is expected that the bio-based solution will initially be produced in small quantities.

Mechanically recycled content typically has a lower carbon footprint than virgin materials, but we need to include some "virgin-like" or alternative virgin resources, in other words, plant-based materials, which have a lower carbon footprint than petroleum-based materials.

Q: Looking ahead, is there a roadmap for commercializing this solution at scale? In terms of long-term strategy, will bPET eventually reach a point where it is comparable to PET/glass/aluminum?

A: We believe that plant-based plastics have a key role to play as part of our overall PET blend, as well as recycled PET content from both mechanical and enhanced recycling sources. Working in tandem, these three technologies can work together to recycle and help us close the packaging loop. Our infographic outlines our approach to reducing virgin oil-based plastics.

We are very much looking forward to seeing the first commercial facility using bMEG technology, jointly owned by Coca-Cola and Changchun Meihe Technology, when UPM starts up its plant in 2023. This innovative technology has been licensed and we encourage others interested in investing in the bioeconomy to contact The Coca-Cola Company or Changchun Meihe Technology for a more detailed discussion.