Degradable plastics are difficult to "degrade" (need to be degraded under specific conditions), which has always been the focus of controversy. There are also different opinions on the degradation performance of common degradable plastics such as PLA or PBAT under natural conditions.

The “plastic limit” policy currently being implemented is even more questioned as a “wrong route” by many people when the composting facilities are not fully constructed.

However, in the development process of degradable plastics, new degradation technologies continue to emerge, with various degradation methods. For example, the bioplastics that can be completely degraded in slightly high temperature hot water, which have been forwarded in large quantities some time ago, are amazing because of their good degradation performance and unique degradation technology.

In fact, there are countless various degradation methods in the development of degradable materials. Here is a brief inventory.

1. Specific degrading flora.

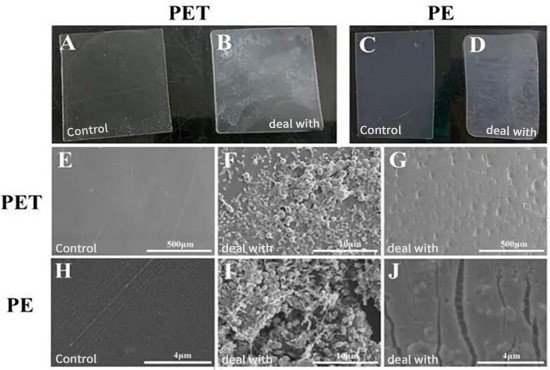

On April 25, 2021, a paper published by Sun Chaomin's team from the Institute of Oceanology, Chinese Academy of Sciences, China, showed that some marine microorganisms can effectively degrade polyethylene (PE) and terephthalate (PET) plastics. PE can be degraded into fragments in two weeks! The latest discovery of PE degrading enzyme by Chinese Academy of Sciences!

Since 2016, the research team has collected thousands of plastic wastes from the coastal waters of Qingdao, China. After a large number of screenings, it was found that a bacterial colony attached to a plastic waste has obvious colonization and degradation capabilities on the surface of PET and PE.

Marine microbial flora can effectively colonize and degrade PET and PE plastics

Researchers speculate that these bacteria obtain additional energy by degrading plastic. Through the quantitative analysis of the types and abundance of the bacterial group composition, it was found that there are 5 types of bacteria as the dominant population. Combined with the culture technology, the pure culture strains of the above 5 types of bacteria were successfully obtained, of which 3 strains have obvious plastic degradation ability. These 3 strains of bacteria were compounded according to a certain ratio, and successfully obtained a flora that can coexist stably and significantly degrade PET and PE plastics. This flora especially likes to degrade PE plastics, which can degrade PE into fragments in two weeks.

2. Embedding enzymes in the manufacturing process

Not long ago, an article on the rapid degradation of compostable plastics published in the April issue of Nature caused heated discussion. This is a paper by Ting Xu, professor of materials science and engineering at the University of California, Berkeley, as the main author.

Their core process is to embed polyester phagocytic enzymes in the manufacturing process of compostable plastics, which can greatly shorten the degradation time of degradable plastics. The new technology of American universities makes "biodegradable" plastics truly compostable.

Picture: (left) a modified plastic (right) decomposed in only three days in standard compost, and completely decomposed after two weeks

To initiate degradation, water and heating are required. At room temperature, 80% of the modified PLA fiber can be completely degraded within a week. The higher the temperature, the faster the degradation rate. Under industrial composting conditions, modified PLA degrades within 6 days at 50°C. PCL (polycaprolactone), another polyester plastic, degrades within 2 days under industrial composting conditions at 40°C.

For PLA, she implanted an enzyme called proteinase K to chew the PLA into lactic acid molecules; for PCL, she used lipase. Both of these enzymes are inexpensive and easily available.

3. Add easily hydrolyzable fragments to the molecular chain

In November 2020, Ji Junhui from the Institute of Physics and Chemistry of the Chinese Academy of Sciences announced that the team has developed a seawater-degradable plastic that is expected to cut off marine plastic pollution. This new type of degradable plastic introduces easily hydrolyzable fragments into the main chain of PBS or PBAT, such as PBS-GA, PBS-LGA, PBA-GA, PBA-LGA, PBAT-GA, PBAT-LGA and a series of biodegradable plastics. The best technology: PBS and PBAT introduce easily hydrolyzable fragments, and seawater degradable plastics are born!

The construction of seawater degradable material system is the design of copolymerization molecule/two-phase structure including: non-enzymatic hydrolysis and biodegradation. Introducing easily hydrolyzable fragments into the main chain of biodegradable polyester, designing and constructing a new type of seawater degradable copolyester, combining non-enzymatic hydrolysis and biodegradation,use rapid non-enzymatic hydrolysis to accelerate non-enzymatic hydrolysis and the depolymerization of polyester long chains to short chains, thereby inducing and strengthening the subsequent biodegradation and mineralization process of the material.

Ji Junhui’s team has developed a series of (PBS-GA, PBS-LGA, PBA-GA, PBA-LGA, PBAT-GA, PBAT-LGA) structures that can have certain applications in terms of performance based on different performances. According to the results, the degradation conditions of laboratory simulation of seawater degradation, Xisha degradation site, and Bohai Sea sampling are all relatively good.

4. New technologies need time to test

In addition to the above degradation technologies, PET degrading enzymes, experts from the Chinese Academy of Sciences modified PET degrading enzymes, and new degradation technologies such as complete degradation of PET at 37°C are also emerging.

But all new and beautiful technologies have a "curse" that cannot be escaped-they cannot be industrialized, are limited to the laboratory environment, or eventually cause unexpected new problems, which can only be tested by time.

For example, in the early days, adding additives to PE plastics was regarded as the most convenient way to solve plastic pollution, but subsequent research found that this method could not really solve the problem of plastic pollution, and instead produced more serious microplastic pollution.

Perhaps, with the continuous enrichment of degradation methods and the real industrialization of degradation technologies from the laboratory, degradable plastics will usher in a wider market.