Plastic is one of the biggest contributors to marine pollution, and it accounts for more than 50% of the plastic waste problem. In the context of increasing environmental pollution, more and more people are putting hard work into the application of green and renewable materials. This article looks at 5 major new bio-based environmentally friendly packaging materials: banana leaves, pineapple leaves, coffee grounds, peanut shells, apple pomace, see what you know?

Banana leaves made of environmentally friendly tableware

The Thais have gone above and beyond in sustainable packaging!

As the most natural biodegradable material, many Thai desserts are wrapped with banana leaves or banana leaves on the outside. The rich green color not only makes the dessert look more attractive, but also adds a touch of aroma. Many supermarkets have also begun to use leaves to package vegetables, greatly reducing the use of plastic bags, convenient and environmentally friendly. The tableware at the 2019 ASEAN Summit also chose plates and bowls made from compressed banana leaves, an environmentally friendly concept that was well received.

Pineapple leaves

Designers of eco-friendly packaging designed to interact with designs that allow a deeper understanding of seeds and plants, rather than throwing away the packaging! The plantable nature of the design ensures that its life does not end immediately after consumption, and that its use evolves before, during and after use - the idea of a circular economy combined with sustainable design. Each seed is carefully selected and these seeds can be seamlessly embedded into the pineal body material.

The outer packaging made of discarded pineapple leaves

The outer packaging, a special paper made from discarded pineapple leaves, is the result of an initiative launched by the Philippine Design Center to promote local communities and resources, especially because the Philippines is one of the world's largest producers of pineapple fruit. The design helps eliminate unnecessary waste and encourages locals to actively contribute to the conservation of Philippine flora.

Coffee cup" made of coffee grounds

German companies design and manufacture a variety of eco-friendly coffee cups, and their latest masterpiece is a take-away cup made from discarded coffee grounds.

Whether at home, at the office, or on the go, many people enjoy a nice cup of coffee in the morning or evening. But what do you do with the coffee grounds after you've finished brewing? In addition, according to the International Coffee Organization, approximately 600 billion paper and plastic cups are used and discarded worldwide each year, making this a compelling environmental issue.

So, the designer thought of doing something with the coffee grounds instead of just throwing them away for nothing. After 3 years of experimentation, he finally developed a new material that can be used to manufacture products - Kaffeeform. To develop this material, he collected coffee grounds from all the local cafes in Berlin, dried them and mixed them with biopolymers, starch, cellulose, wood, natural resins, waxes and oils. The resulting composite has several advantages: it is biodegradable, lightweight, and has the taste of coffee and the appearance of dark wood.

In 2015, Kaffeeform launched their first product, an espresso cup, followed by a cappuccino cup in 2016. In 2018, they went on to design and manufacture the Weducer mug, which can be used as an alternative to paper cups.

While these cups were originally designed for long-term use, as well as being biodegradable at the end of their useful life, the whole process is green and worry-free. But Kaffeeform also offers a new and additional service: it recycles the cups after use and transforms them into 3D printable filament for extruding tiles or new cups. It's a great way to get the most out of your cups!

Peanut shells

This spoon made of peanut shells is actually seed packaging, used to pack a seed, use the spoon directly with the peanut shells, plant seeds to the appropriate depth. Finally, the user can crush the shovel, put it in the soil, and it turns the spoon into a fertilizer for the seeds!

The best packaging design innovations always design creative packaging while satisfying sustainability and a great user experience.

If you add a groove to this peanut shell spoon with the size of the seeds, set the seeds into it, and then add a scale to the spoon, so that users can simply grasp the depth of planted seeds, but also easy to break, at the same time, the production process to add the nutrients needed by the seeds, so that the seeds are more likely to germinate and grow, so will it be more like consumers?

The whole process is highly poetic, the product packaging has a purpose at every stage and produces no waste, is environmentally friendly, environmentally sustainable, and there is no waste!

apple dregs

According to Oregon State University, Professor Yan-Yun Zhao is currently leading her research group to make key progress in the research and process of producing a new environmentally friendly packaging material using apple pomace as the main raw material, which is expected to replace the currently widely used plastic packaging material.

"Currently, apple pomace is usually just composted or used as animal feed," said the study, which aims to reduce food loss and waste throughout the food supply chain. "We thought why not turn it into an environmentally friendly product that meets the needs of the industry."

Use apple pomace as a key component in pulp molded packaging products such as take-out containers, flower pots, beverage cartons, bottles and flip-top packaging for fruits and vegetables. Apple pomace is used, in part because it is readily available in the Pacific Northwest. When apples are processed into juice, about 70-75% of the apples go into the juice, leaving 25-30% as pomace.

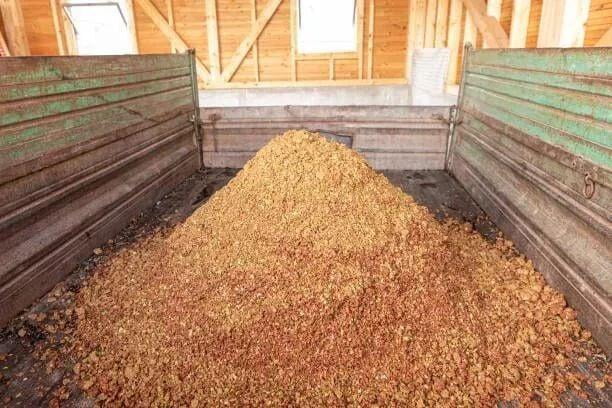

Apple pomace is often composted or used as animal feed

The raw materials used in the new packaging material are not limited to apple pomace, but also include residues from other fruit and vegetable juicing and waste grape pomace from wine production. The main raw material for the production of molded pulp products such as food overwrap and food trays as well as beverage containers has always been recycled waste newspaper, and the biggest advantage of this molded packaging material is that it is naturally degradable. However, as the amount of recycled newspaper decreases year by year, scientists are actively looking for alternative production materials, and new uses for apple pomace have emerged. Currently, Yan-Yun Zhao's team has obtained a patent for the production process of apple pomace packaging material.