In 2021, two hot words frequently appear in people's lives-"carbon neutrality" and "plastic ban". The interpretation of the concept of carbon neutrality has long been promoted by many media, and Tesla, who made his fortune through “carbon trading” some time ago, made a vivid commentary on the term “carbon neutrality”—not only environmental protection, but also make money.

At first glance at the hot words "plastic ban" and "carbon neutral", it is not difficult for people to link them together, and the causal relationship can even be clearly seen.

The so-called ban on plastics means the prohibition of the use of disposable plastic products (non-degradable). This action not only directly reduces "white pollution", but also indirectly reduces the mining of fossil raw materials, energy consumption, and the core concept of "carbon neutrality" ( Reduce carbon emissions) is an incomparable fit.

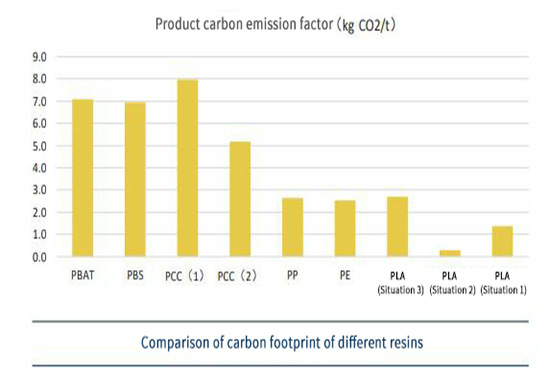

Under certain circumstances, the carbon emissions of bio-based plastics such as PLA are lower than that of traditional plastics, which is more conducive to "carbon neutrality."

1. Introduction to degradable plastic products

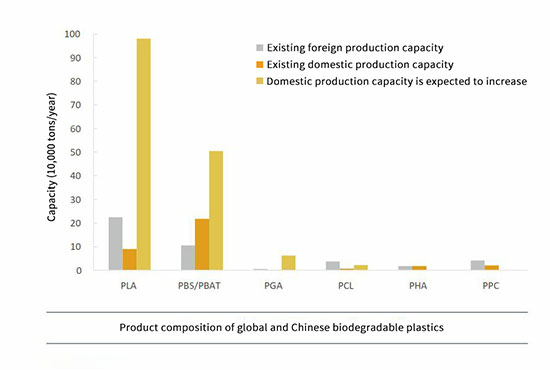

At present, the common degradable plastics on the market can be divided into bio-based degradable plastics and petroleum-based degradable plastics according to their raw material sources. The raw materials of bio-based plastics are derived from biomass. For example, polylactic acid PLA, which is a common degradable plastic straw material on the market, is obtained from the fermentation of corn. For petroleum-based degradable plastics, the raw materials are derived from petroleum extraction, which is the same as traditional plastics, such as PBAT, a common material used in film bag plastic products.

PLA is used for almost all kinds of plastic applications in injection molding, film, sheet, and fiber, and is considered to have the potential to gradually replace traditional plastics. The first generation PLA uses agricultural products such as grains and cassava as raw materials (there is a risk of land competition with grain), and the second generation PLA uses agricultural and agricultural product processing residues such as straw as raw materials.

PBS is formed by polycondensation of SA (succinic acid) and BDO (1,4-butanediol). It is currently recognized as the best comprehensively degradable plastic variety in the world, but it has two shortcomings: poor tear resistance and toughness is not high.

PBAT is a thermoplastic degradable plastic with good film-forming properties. It can overcome the shortcomings of poor tear resistance and low toughness of PBS. It is a degradable plastic category that replaces traditional plastics with the most technical and cost advantages.

PPC is an alternating copolymer of CO2 (carbon dioxide) and PO (propylene oxide), which is evaluated as "suppressing greenhouse gas emissions". PPC has high barrier properties (oxygen barrier properties) and biocompatibility, and is currently mainly used in agricultural film, food and pharmaceutical packaging, tableware and other fields.

2. Comparison of the carbon footprint of biodegradable plastics and traditional plastics

Carbon footprint refers to the collection of greenhouse gas emissions caused by corporate institutions, activities, products or individuals, and in most cases refers to carbon dioxide emissions.

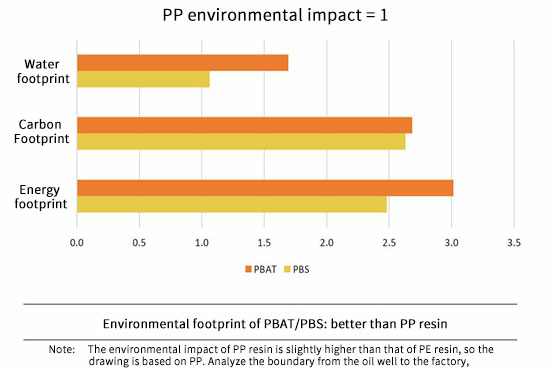

(1) PBAT and PBS

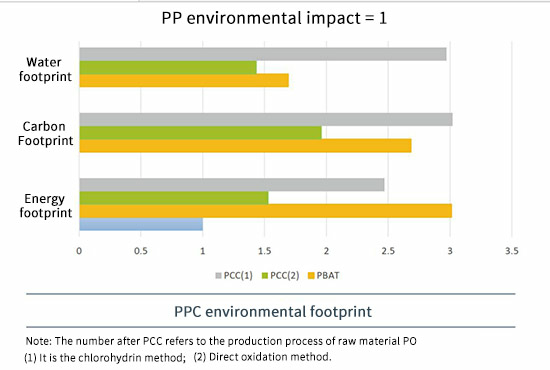

The carbon footprint of common petroleum-based biodegradable raw materials, PBAT and PBS, and the environmental impact of traditional PP resins. The raw materials of PBAT and PBS are petroleum extraction and do not have green attributes in terms of the source of raw materials.

And in terms of carbon footprint, to start from the well to the analysis of the polymerization plant footprint boundary PBAT PBS and similar, is more than 2.5 times for PP.

In other words, PBAT and PBS have more carbon emissions than traditional plastics and are not conducive to the realization of carbon neutrality. There is no equal sign between "degradable" and "carbon neutral".

(2) Biodegradable plastic PLA

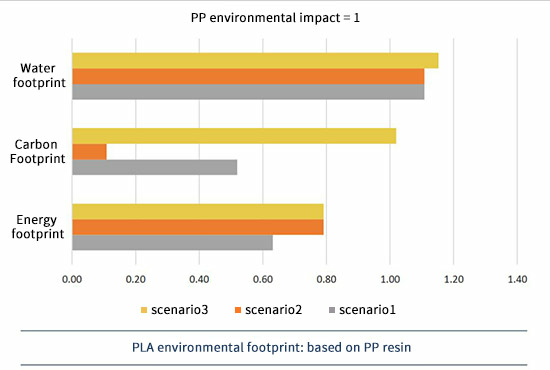

The biodegradable plastic PLA is mostly derived from corn fermentation. The report sets up three scenarios to compare the carbon footprint of PLA degradable plastic and ordinary petroleum-based plastic PP.

Scenario 1 Consider not only the carbon storage function of corn, but also the energy utilization of straw in the industrial chain. Assuming that 50% of the straw is collected for energy production, the energy conversion efficiency is 45%.

Scenario 2 Only considering the carbon storage function of corn is the actual situation of PLA production in China.

Scenario 3 Neither the carbon storage function of corn nor the utilization of straw are considered. It describes the situation where PLA plastic is discarded in nature and cannot be degraded in the natural environment.(PLA plastic needs to be degraded under composting conditions)

In the scenario 2 that simulates the actual production of PLA in China, the carbon footprint of PLA per ton is less than 10% of PP. This is due to the transfer of crop carbon pool functions from grains to PLA products along the product chain. However, the carbon emissions of grain production residues, that is, straws, etc., occur outside the analysis boundary and become the invisible "solid waste baggage" of PLA raw materials.

When PLA is abandoned after use (Scenario 3), the carbon fate of PLA products is not essentially different from that of traditional plastics. In other words, in the case of scenario 2, PLA plastics have lower carbon emissions, which is more conducive to the realization of carbon neutrality.

(3) PPC capable of absorbing carbon dioxide

PPC (polypropylene carbonate) is an alternating copolymer of CO2 and propylene oxide (PO), which is evaluated as "suppressing greenhouse gas emissions."The product has high barrier properties (oxygen barrier properties) and biocompatibility, and is currently mainly used in agricultural film, food and pharmaceutical packaging, tableware and other fields.The consumption ratio of carbon dioxide and PO (propylene oxide) for the production of pure PPC is about 40%: 60%. There are three processes for PO synthesis: chlorohydrin method, indirect oxidation method, and direct oxidation method.

When PO comes from the chlorohydrin process, the energy consumption to produce 1 ton of pure PPC is 2.5 times that of PP, and the resulting carbon footprint is 3 times that of PP. When PO comes from the direct oxidation process, the unit PPC carbon footprint is only about 60% of the chlorohydrin process.

The process has a high degree of environmental friendliness, but it is technically difficult. Compared with traditional PP plastics, the carbon emissions per unit mass of PPC are greatly affected by the process. Among them, the direct oxidation method is more environmentally friendly, but the carbon emissions are much higher than that of PP plastics.

3. Conclusion: Degradable is not necessarily low carbon

At the end, the carbon footprint of different resins is summarized and compared. It can be seen that, based on unit mass, degradable plastics are not necessarily low-carbon.

The use of plastic is determined by function. In the case of the same functional units, the material demand of new-generation plastic products is generally higher than that of traditional plastic products. For example, 1.5~2 kg of PBS plastic pallets are functionally equivalent to 1 kg of PP plastic pallets. In functional units, the environmental impact of PBAT plastic and PBS plastic is usually greater.

In the current situation where a large amount of degradable plastics are sent to incineration, “plastic ban” cannot be equated with “carbon neutrality”.

At the same time, we can also see that in order to achieve carbon neutrality, raw material innovation is an inevitable measure. The carbon emissions of plastic production mainly come from two aspects, raw material mining and energy consumption.

Bio-based plastics such as PLA, whose raw materials come directly from plants, and the carbon in plants come from the atmosphere, indirectly form a closed-loop structure, which is more conducive to the realization of carbon neutrality.

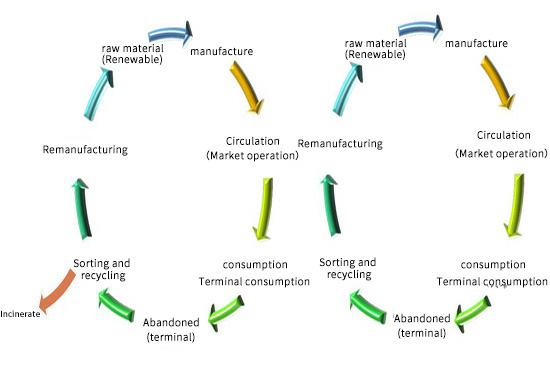

In addition, the report also pointed out that it is particularly important to promote the plastic economy from an open-loop linear model to a closed-loop circular model. Only when all links are used effectively can the environmental impact be minimized, which is more helpful to the realization of carbon neutrality.