Regarding the question of whether polylactic acid PLA can be degraded in seawater, different experts may come to different conclusions through experiments. Some expert studies have found that PLA can be completely degraded in a specific body of water. The specific water body referred to by the expert team is in a fish tank with the sea sand of Beidaihe, the sea mud of Ningbo, and the sea water of Beidaihe in China at room temperature. Experimental observations have found that the biaxially stretched PLA film can be completely degraded.

Some other experts found that PLA is basically non-degradable in seawater tests. On November 17, 2020, Ji Junhui, a researcher at the Institute of Physics and Chemistry of the Chinese Academy of Sciences, said at the China Biodegradable Resin Symposium held by the Shenzhen Polymer Association:"Unlike terrestrial soil, there are very few microorganisms in seawater, and the temperature of seawater is relatively low. Biodegradable plastics cannot be degraded in seawater as they are on land, or they cannot be degraded in seawater for a long time."

01 Multiple research conclusions: PLA basically does not degrade in seawater

In 2010, the Agricultural University of Athens, Greece used the actual Mediterranean soil to do the degradation test of PLA biodegradable plastics. The 11 months were only part of the physical body and part of the fragmentation.

In 2014, Central South University of Forestry and Technology simulated natural soil and buried a plastic bag made of PLA in the simulated natural soil. After 12 months, its mass lost only 0.23%, with almost no degradation.

The environment is an important factor affecting the degradation performance of biodegradable materials. The seawater environment is completely different from the soil or compost environment. Low temperature, strong fluidity, high salt and high pressure are the main characteristics of the marine environment. In the marine environment, most of the microbes are distributed in the near-coastal areas, and the microbial content in the far sea areas is low or even absent.

In 2017, the 400-day test conducted by the University of Myloit in Germany showed that various biodegradable plastics were degradable in industrial composting and placed in seawater and fresh water. In the end, the PLA had only about 0.5% mass loss.

In 2017, the Institute of Physics and Chemistry of the Chinese Academy of Sciences and the National Engineering Research Center for Engineering Plastics organized nearly 10 PhDs to study seawater biodegradable plastics.

The results of this research "Degradability of typical biodegradable polyester in seawater" were published in the "Journal of Functional Polymers" in October 2020. Dan, Zhang Wei, Ji Junhui, the article pointed out that PLA basically does not degrade in 6 different water bodies.

02 How to test the degradation performance of PLA in seawater

Ji Junhui et al. studied the impact of environmental factors on the degradation performance of the four widely used biodegradable polyesters in different water bodies. The specific test information is as follows.

(1) Experimental conditions

1. Test materials: PLA, PBAT, PBS, PCL.

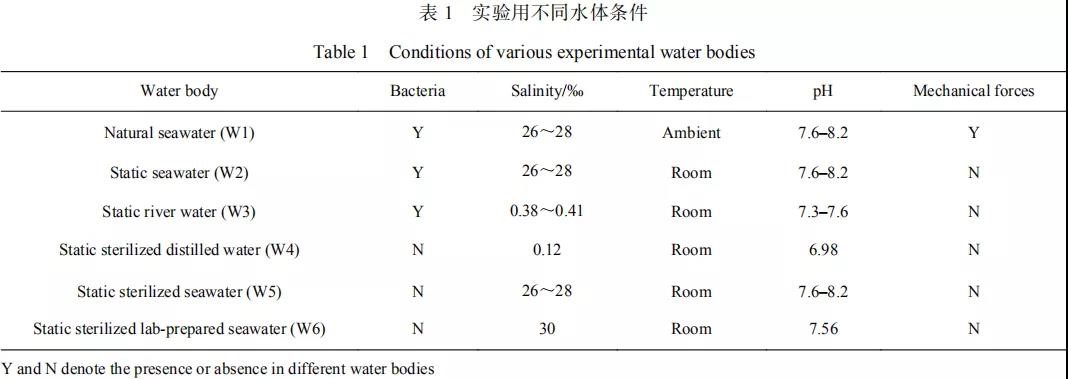

2. Experimental water bodies: natural sea water, static sea water, static river water, distilled water, sterilized sea water, homemade sea water. Natural seawater (W1) is the natural seawater on the coast of Bohai Bay in China; Static seawater (W2) is to transport the natural seawater from Bohai Bay in China to the laboratory; The static river water (W3) transports the water from the Qinghe River in Beijing to the laboratory; Sterilized distilled water (W4) is prepared by adding 5‰ Kazon antibacterial agent to distilled water; Sterilized seawater (W5) is the natural seawater that is transported to the laboratory, and then 5‰ of the Kason antibacterial agent is added to it; Homemade sea water (W6) is a laboratory-made sterile high-salinity water. The preparation method is: add 483.38gNaCl, 103.94gMgCl2, 22.76gCaCl2, 14.91gKCl, 81.04gNa2SO4, 4.19gNaHCO3, 1.67gNaBr in 20 L of distilled water, and then add casson antibacterial agent with a water mass of 5‰;

Salinity and pH are the actual test values of the water body, which fluctuate within a certain range according to the environment and seasonal changes of the water intake. The conditions of different water bodies are shown in the table below.

(2) Degradation

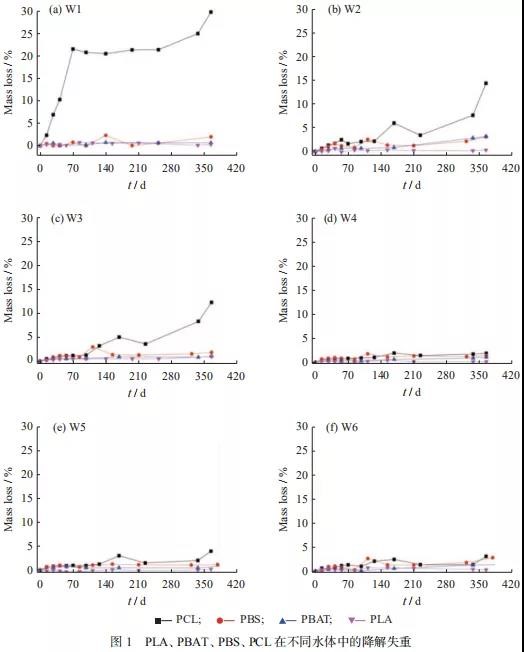

The degradation and weight loss rates of 4 kinds of polyester splines in different water bodies were studied.

The fast-degradable polyester in the compost has significantly reduced weight loss in different water bodies. Except for PCL, which has obvious weight loss in the bacteria-containing water body, the other polyesters have no obvious weight loss in the 6 experimental water bodies.

In the same degradation environment, PCL is more degraded than other polyesters, which largely depends on the widespread presence of microorganisms that can degrade PCL in natural water bodies, while there are relatively few microorganisms that can degrade PBAT, PLA, and PBS in water bodies.

Degradation and weight loss rate of 4 kinds of polyester splines in different water bodies

Degradation and weight loss of PLA PBAT PBS PCL in different water bodies

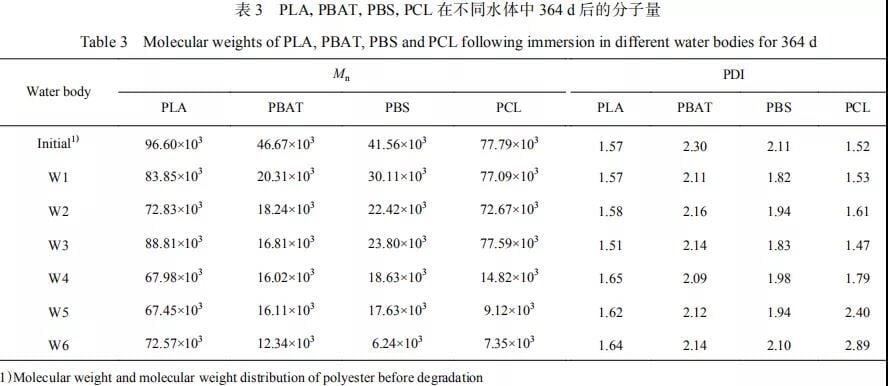

The number average molecular weight (Mn) and molecular weight distribution (PDI) of the four polyesters before and after degradation were studied.

The molecular weight of PLA before and after degradation in the 6 kinds of water bodies decreased only slightly. This result is consistent with the change in weight loss. The molecular weight reduction of PLA in the sterilized water body seems to be more obvious.

PCL has significant weight loss in bacteria-containing water, but its molecular weight does not change significantly before and after degradation. The degradation of PCL in bacteria-containing water is a typical surface corrosion mechanism. As the degradation progresses, the degradation products peel off layer by layer, and the size of the material decreases, but the number average molecular weight of the remaining material is always maintained above 70×103, which is basically unchanged compared with the initial value.

In sterile water, the molecular weight of PCL is significantly reduced, especially in high-salinity homemade seawater, the number average molecular weight is reduced from 77.79×103 to 7.35×103, and the molecular weight distribution becomes wider. This shows that the degradation is the main degradation mechanism at this time. As the salinity increases, the PCL molecular weight changes more obviously, which corresponds to the weight loss result, which further shows that the inorganic salt has a certain promotion effect on the degradation.

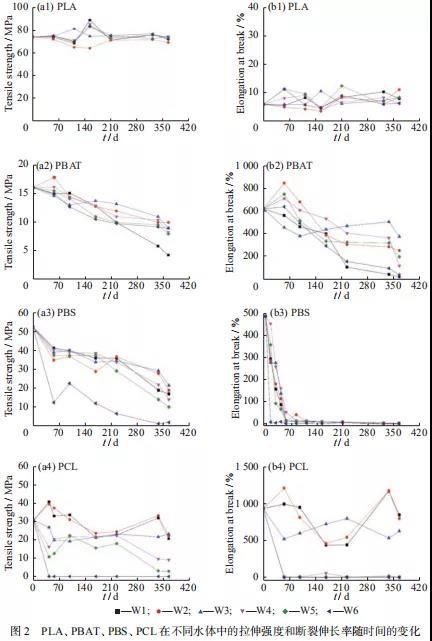

The tensile strength and elongation at break during the degradation process of 4 kinds of polyester splines were studied.

The tensile strength and elongation at break of PLA did not change significantly during the degradation process. Combined with the weight loss rate and molecular weight test results, it shows that the weak molecular weight change of the sample does not change the mechanical properties of the material.

The change of the mechanical properties of PCL presents two trends. In the water containing bacteria, due to the degradation mechanism of surface corrosion, the material degrades from the surface without significant internal changes, so the mechanical properties of the test specimen remain unchanged.

In the initial stage of degradation, there is a certain plasticization phenomenon due to the entry of water molecules; in sterile water, the internal molecular weight of PCL is significantly reduced due to the degradation of the body, and the mechanical properties change significantly with the extension of the degradation time; the mechanical properties are completely lost in the homemade seawater for about 56 days.

Tensile strength and elongation at break during the degradation of 4 kinds of polyester splines

Changes of tensile strength and elongation at break of PLA PBAT PBS PCL in different water bodies with time

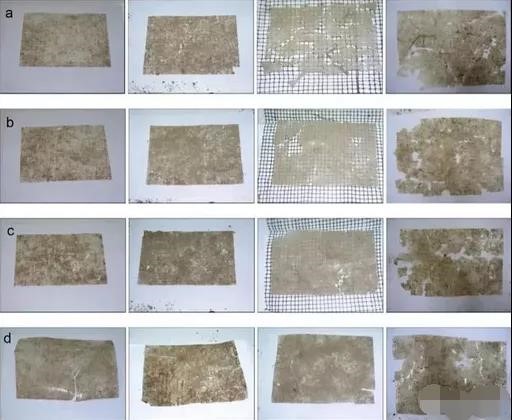

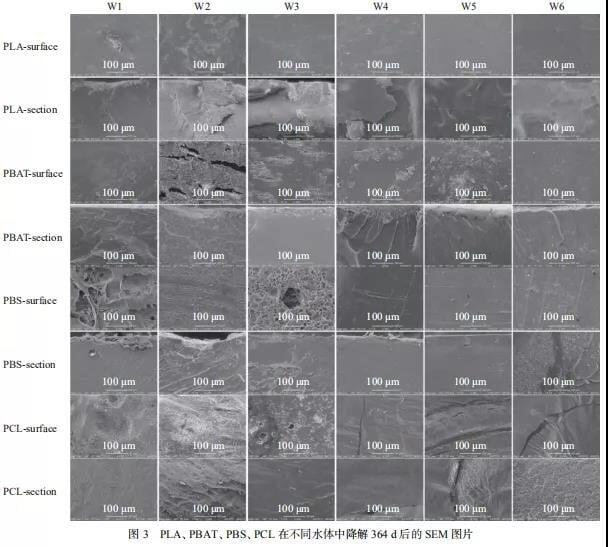

After the 4 kinds of polyester splines were degraded for 364 days in 6 different water bodies, their surface and cross-section were tested by SEM, as shown in the figure below.

SEM pictures of PLA PBAT PBS PCL degraded in different water bodies after 365 days

After the degradation of PLA, the surface and cross-section did not change significantly, which was consistent with the analysis results of weight loss and molecular weight change, indicating that PLA in the six water bodies was basically not degraded.

After PCL is degraded in bacteria-containing water, the surface also shows obvious degradation holes, but the internal section of the sample is flat, which is the result of a typical surface corrosion degradation mechanism; In the sterile water body, the surface and section of PCL showed obvious hydrolysis cracks, indicating that the PCL had an obvious non-enzymatic hydrolysis process at this time.

(3) Test conclusion

Studies have shown that the degradation performance of biodegradable polyester in natural seawater is significantly lower than that in composting. In 6 different water bodies, PLA basically does not degrade; PLA hardly degrades in natural seawater within 364 days, and there is no obvious change in molecular weight, weight loss, mechanical properties, etc. The weight loss of PBAT and PBS within 364 days is not more than 3%, and the degradation rate is slow. Although the molecular weight and mechanical properties have been significantly reduced, there is no significant weight loss. PCL degrades the fastest and exhibits a surface corrosion mechanism in seawater. After 364 days, the weight loss rate is 32%. As the degradation progresses, the size of the material gradually decreases but the molecular weight and mechanical properties remain unchanged.

Microorganisms are a key factor affecting the rate of biodegradation, and high concentrations of inorganic salts can promote the process of non-enzymatic hydrolysis to a certain extent.

Ji Junhui delivered a speech at the China Biodegradable Resin Symposium

03 Future development direction

Can the biodegradable plastic (PLA) be degraded in the absence of any treatment of seawater (in the natural environment)?

The answer is no.

Because biodegradable plastics are mostly polymer materials containing ester bonds, their molecular chains are relatively fragile and can be decomposed and digested by many microorganisms in nature, and eventually form carbon dioxide and water.

"Unlike terrestrial soil, there are very few microorganisms in seawater, and the temperature of seawater is relatively low. Biodegradable plastics cannot be degraded in seawater as they are on land, or they cannot be degraded in seawater for a long time." Ji Junhui Expressed in Haikou on November 17, 2020.

Then, the degradable materials used in the seawater environment are more inclined to the degradable materials with better hydrolysis performance. Under the circumstance that the degradation environment does not change, it is particularly important to research and develop water-degradable materials with excellent water-degradability in order to solve the problem of marine pollution more efficiently.

At present, there are relatively few studies on the degradation of degradable materials in seawater environment. The author believes that if the material is to be water-degradable, it is a better way to modify the material itself.

In the research and preparation of water-degradable materials, adjustments and modifications can be made according to the mechanism of biodegradation. The essence of biodegradation is to hydrolyze or enzymatically hydrolyze the bonds of the internal structure of the material. Based on the degradation mechanism of polymer materials in water environment, future research can start from the following aspects.

1. Select synthetic polymer degradable materials with more hydrolysis bonds such as amide bonds, ester groups, enamine, amino groups, and amide groups as the basic materials, and at the same time there are more hydrolysis bonds inside the materials. In addition, there are more straight molecular chains, fewer molecular side chains, lower molecular cross-linking, fewer internal hydrogen bonds, better molecular flexibility, and lower molecular crystallinity.

2. Adding more water-soluble groups and acidic or basic groups to the material molecules through polymerization reaction, the acidic and basic environment can make it more prone to hydrolysis.

3. Blending and compounding with other degradable materials to develop degradable polyester/urethane, fatty ester/amide ester, fatty ester/aromatic ester polymers, which can be hydrolyzed or decomposed by microorganisms and enzymes.

4. Using natural polymer materials with excellent biocompatibility and degradability as raw materials, first induce free radicals on natural polymer materials, and use its activity to compound with polymer monomers with hydrolysis properties to improve molecular solubility. Improve the mechanical strength of molecular materials and improve their practicability through modification and other means.