On December 16-17, 2021, the European Commission held a seminar on the revision of the FCM regulation on recycled plastics with the Joint Researchcenter (JRC) and other institutions. As an invited representative, Guangzhou Customs Technology Center (IQTC) participated in the whole seminar and technical exchange.

On 12-23, 2021, Dr. Bastitaan of European Commission was invited to share the topic of revised regulations on recycled plastics for food contact at the 2021 International Food Contact Material Safety Forum (2021 FCS symposium) as well.

01. Current EU regulations related to recycled FCM plastics

The current EU regulations related to recycled FCM plastics are mainly as follows.

1 / (EU) No 1935/2004 EU Food Contact Materials and Articles Regulation

The regulation is the framework regulation of the EU on food contact materials and articles, which provides the basis for ensuring people's health and consumers' interests, as well as ensuring the effective operation of the EU internal market.

The regulation applies to all food contact materials and products that come into contact or are expected to come into contact with food and provides general rules and procedures for FCM, including requirements for safety, definitions, labeling, traceability, inspection and control.

2 / (EU) No 10/2011 Regulation on plastic food contact materials and articles

The regulation specifies the requirements for the use and sale of plastic materials for food contact and their products on the EU market, including the list of authorized substances, exemptions for substances outside the list, total migration limits, specific migration amounts, and declaration of conformity.

Therefore, if FCM products prepared from recycled plastics need to meet the requirements of the regulation.

3 / EC No. 2023/2006 EU GMP regulation for the production of food contact materials

The regulation specifies the requirements for the production of plastic materials for food contact and their products, including quality assurance systems, quality control systems, documentation and record-keeping requirements, and gives detailed rules for good manufacturing practices.

Therefore, the use of recycled plastics for the production of FCM also requires ensuring that the entire process meets the requirements of GMP regulations.

4 / (EU) No 282/2008 EU Regulation on food contact recycled plastics

The regulation is a specific EU regulation on recycled plastics for food contact. The regulation puts forward the main requirements for recycled plastics and products for food contact, including the setting of the scope of recycled plastic materials and products for food contact, the authorization conditions for the regeneration process, the authorization procedures for the regeneration process, the supervision and inspection requirements, and the requirements for the declaration of conformity.

According to (EU) No 282/2008, recycled plastics should be manufactured by an authorized process. However, provided that the relevant requirements of (EU) 10/2011 are met, the following materials may be exempted from the regulation.

Recycled plastics made from chemical degradation resulting in monomers or starting materials.

Recycled plastics produced from trimmings and scraps recovered in the production area.

Recycled plastics that are used after the functional barrier layer.

02. Problems with the current FCM regulations on recycled plastics in the EU

The assessment report completed by the European Commission points out that the EU FCM recycled plastics regulation (EU) No 282/2008 has been introduced for more than 10 years, from the implementation of the situation, there are many problems, mainly including.

1 / Regulatory applicability issues

(EC) No 282/2008 establishes specific requirements for the recycling process to ensure that recycled plastic materials and articles intended for food contact meet the requirements of Article 3 of Regulation (EC) No 1935/2004, but it does not apply to all recycling technologies.

Because only a few recycling technologies exist when regulations are developed, these technologies are not necessarily applicable to all recycling scenarios, such as those that have been authorized, HDPE recycling technologies are not fully applicable to rPET; and some new recycling technologies, such as closed-loop recycling, are applicable but have not been authorized.

(EC) No 282/2008 provides rules for the use of certain technologies for the production of recycled plastics, and the use of recycled materials is also subject to the requirements of (EU) No 10/2011. (EU) No 10/2011 does not have specific regulations for partial decomposition products or oligomers, but does specify that functional barrier layers are not allowed to contain contaminants that are "mutagenic", "carcinogenic" or "toxic to reproduction", and requires the identification of impurities and risk assessment in all cases, which poses a significant compliance challenge for the recycled plastics industry.

2 / Problems encountered with licensing

The current licensing system in the EU has created many unanticipated problems in the implementation process, such as more applicants, the initial assessment takes up a lot of time, the authorization process is not standardized leading to illegal authorization process, as well as other administrative, procedural and enforcement issues.

3 / Licensing and production issues

According to the current 282 regulations, recycled plastics can only be produced after the assessment of the permit. In practice, however, some recycled plastics are already on the market in accordance with the domestic regulations of each member state before the EU permits them.

For these reasons, the EU is preparing to draft a new FCM regulation for recycled plastics to replace (EU) No 282/2008.(EU) No 282/2008 will no longer be the basis for licensing.

03. The main amendments to the new regulations

1 / Features of the new regulation

1.1 Respond to the requirements of the European plastics circular economy strategy

The regulation is based on the European Circular Economy Plastics Strategy, which sets out key commitments for action at the Union level to curb the adverse effects of plastic pollution.

1.2 Focus on the decontamination process

The regulation states that all plastics recycling processes should include a decontamination process. The process consists of three stages: pretreatment, decontamination and post-treatment procedures. Among them, the assessment and implementation focus on the decontamination process, in order to effectively decontaminate, first from the raw material input control, the proportion of non-food grade materials can not exceed 5%, and need to be crushed and cleaned. Second, recycled plastics must be used under specified conditions. The regulation is more concerned with the technical details of the decontamination process and the quality of the input and output products than with the technical details of the pre-treatment and post-treatment.

1.3 Use of appropriate production technology

The new regulations encourage the use of appropriate technologies for the production of recycled plastics. At the time the new regulations were made mandatory, the main technologies applicable were the physical method of recycling PET and closed-loop recycling. Of these, the physical method requires a license for the recycling process, while the closed-loop method requires only a set of recycling options to be submitted, but no authorization for the process is required.

1.4 Requirement to establish a regeneration program

In order to ensure low pollution levels and achieve easy decontamination, the regulations require a legal entity to be the administrator of the reclamation program and to be responsible for the overall operation of the reclamation program, including the preparation and submission of documents for the hearing of the registration of the program, providing the necessary explanatory documents for all enterprises and institutions involved in the program, and ensuring the accuracy and timeliness of all the above documents.

1.5 Requirement to provide clear and traceable label information

Throughout the turnaround process, the recyclate must have clear and moldable label information. It needs to cover the registration number of the recycling unit, the lot number of the recycled material, the content ratio of the recycled material source, the highest mass percentage of that recycled material in use, and a brief paragraph describing the other documents provided.

1.6 Templates and examples are provided for the documentation required for each segment

The compliance process for recycled material production requires a great deal of documentation, and the text of the new regulation's guidance notes lists the information necessary to present each step of the process and shows the appropriate format and examples. The text covers recycling devices, recycler identification, EFSA documentation, recycling program flow charts, process SOP summary lists and quality assessment documents, providing clear guidance for applicants.

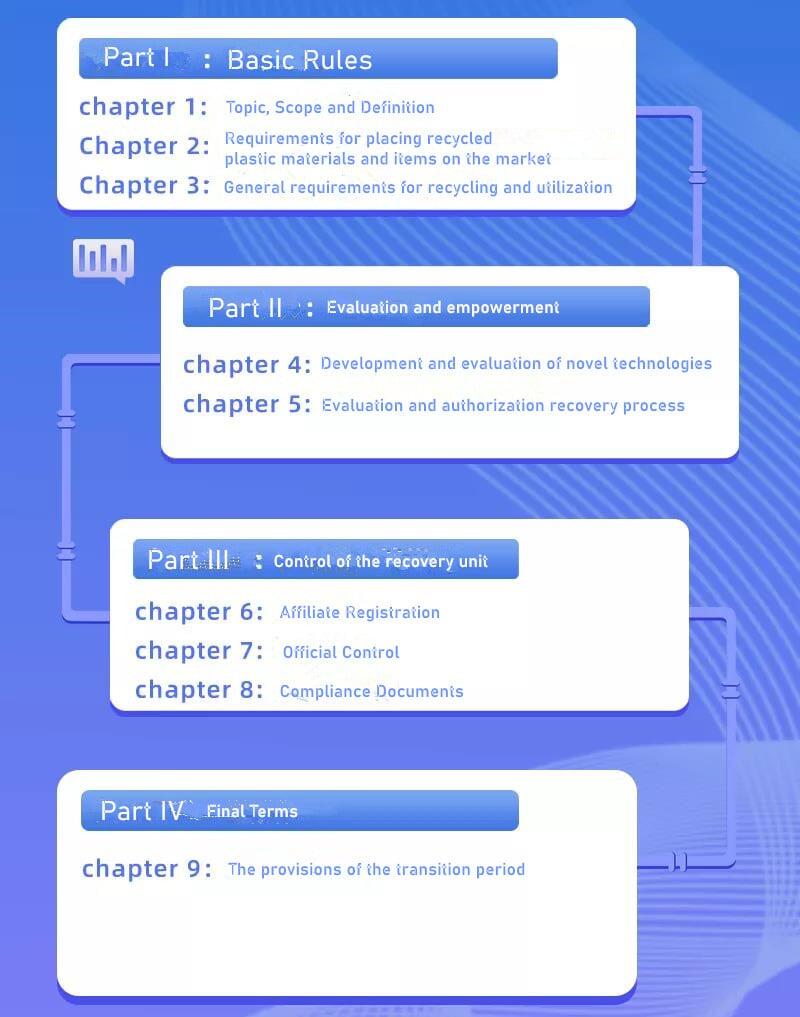

2 / Structure of the new legislation

The new regulations are divided into 9 chapters and 32 articles, with the following general structure.

04. New regulations introduced timeline

December 16-17, 2021: Draft Regulations Workshop

January 10, 2022: Comments due

January-February 2022: Revision based on the collected comments

Earliest 2022-02: Scientific Committee (SC) vote conducted

3 months to conduct an internal EU assessment

1 month time: European Commission (EC) consideration and adoption

July 2022 at the earliest: Effective

05. The impact of new regulations

Based on the assessment of existing EU disclosures, IQTC believes that the implementation of the new regulations will have the following impacts.

The original 230+ applications based on (EC) No 282/2008 will be voided!

Only applications for physically recycled PET will be authorized for a period of time after the implementation of the regulation!

Closed-loop recycling: no authorization is required, but a recycling program needs to be established

HDPE regeneration technology: so far there is not enough data to prove its applicability and further evaluation is needed.

Chemical depolymerization: only those fully depolymerized into monomers are exempted

Barrier layers: manufacturers need to prove their effectiveness

As the revised regulation is still in the consultation stage, there is a possibility of major changes in the final version, therefore, the possible subsequent impact of the regulation needs further evaluation, and it is suggested that the industry needs to pay close attention to the latest progress of the new regulation.