Previously, researchers at the University of Cambridge in the UK found a way to create sustainable, non-toxic, and biodegradable glitter from cellulose, a major component of the cell walls of plants, fruits and vegetables.

The glitter, made of cellulose nanocrystals, is made by altering the light through structural color to bring out vibrant colors. In nature, the glitter of butterfly wings and peacock feathers, for example, are masterpieces of structural color that will not fade over a century.

Bio-based materials, as new materials of natural and renewable origin, not only have the advantages of being carbon neutral and sustainable, but are also safer for humans. Bio-based plasticizers, edible films, polylactic acid for food contact, medical applications, PHA and other bio-based materials are becoming more environmentally friendly and safe options for various industries.

In the mask sector, the demand for beauty and anti-aging products for physiological phenomena such as wrinkles, age spots, dry skin and uneven skin tone has increased significantly in the cosmetics market, and the cosmetics industry continues to grow at a long-term CAGR of 5% to 7%, unaffected by the ups and downs of the global economy. New demographic trends, technology and consumer habits are subtly influencing the development trends of the cosmetics industry. As a result, natural and green cosmetics have become the new directional mark of the industry, and the development of new beauty masks is also a research hotspot for relevant researchers.

Researchers from foreign universities have prepared PHA/starch/PBAT blend films using extrusion method, which have good skin adhesion and compatibility, as well as good kinetic properties for fast and efficient release of surface active ingredients, demonstrating great potential as a raw material for beauty masks.

1. The potential of bioplastics in the beauty mask industry

Polyhydroxy fatty acid esters (PHAs) are bacterially derived biopolymers with very high biocompatibility and low greenhouse gas emission properties that offer excellent potential for environmental and bioengineering applications. Starch is the main carbohydrate reserve in higher plants and is a very abundant biopolymer that is widely used in non-food applications (e.g. glues, thickeners, skin soothing agents, etc.). Polybutylene glycol acid (PBSA) and polyethylene terephthalate (PBAT) are two biopolyester esters with many applications, which are completely renewable and biodegradable in a short time and suitable for the preparation of bioplastic films, combining starch with other products to demonstrate excellent mechanical properties. This study discusses the potential of blends of PHA, plasticized starch and biopolyesters (PBSA and PBAT) as raw materials for the preparation of beauty masks.

2. The new mask production process has a broad development prospect

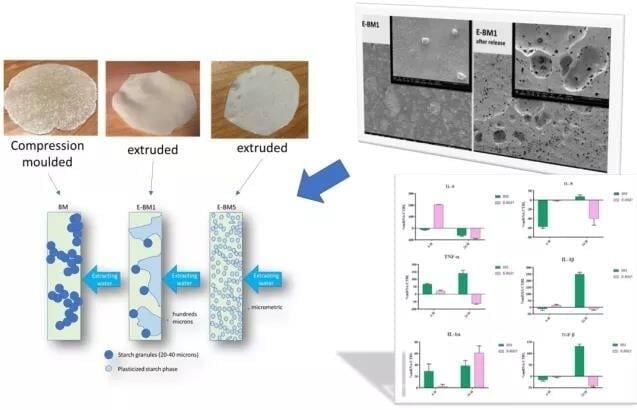

Biopolyester has limited stability at the high temperatures required for the melting process, which is one of the difficulties for industrial applications. In general, the temperature must be controlled to be slightly above the melting point during processing to avoid polymer degradation. In this study, the experimental exploration of different raw material combinations, processing methods and external temperatures revealed that extrusion of polyhydroxy fatty acid ester/starch/biopolyester blend films at 140 °C further improved the properties of the film blends.

For the compression molding production process, the time required to produce the masks is mainly for cutting and packaging, not for film production. Masks produced by automated flat die extrusion plants can be produced in excess of 600,000 units/year, which is more competitive compared to traditional nonwoven industry methods. By examining mesenchymal stromal cells and keratinocytes, the compression molding version of the mixture with a more heterogeneous surface morphology maintains high metabolic activity of keratinocytes, while showing stronger immunomodulatory activity that can effectively aid wound healing and alleviate skin damage and inflammatory states.

In addition, the addition of PBSA and PBAT is also a good strategy. After extrusion processing at 140 °C, the blend films showed good adhesion to the skin after wetting, while these films could release more than 80% of the surface composition within 30 min, which showed fast kinetic properties.

The polyhydroxy fatty acid ester/starch/biopolyester blend film prepared by extrusion in this study represents a promising alternative, demonstrating its great advantages and potential as a raw material for beauty masks. The exploration in terms of selection of ingredients and material processing also indicates the possibility of producing beauty masks with customized properties and processability. In addition, the researchers plan to follow up on the aspect of adding functional additives to the surface of the mask for release into the skin.