Coffee is second only to oil as a highly traded beverage, and the resulting coffee grounds (SCG) are a solid waste. Six million tons of coffee grounds are produced worldwide every day, a very large amount. A large amount of SCG is incinerated or landfilled, which may release harmful substances such as polyphenols and tannins into the environment. There have been a lot of recycling of SCG, and recently, Tala Moussa et al. from the University of Reims, France, used SCG combined with starch to prepare 100% bio-based composite SSCC for upcycling SCG and using it as an insulation material in the construction industry.

The work was published in the journal Materials in a paper entitled "Spent Coffee Grounds as Building Material for Non-Load-Bearing Structures".

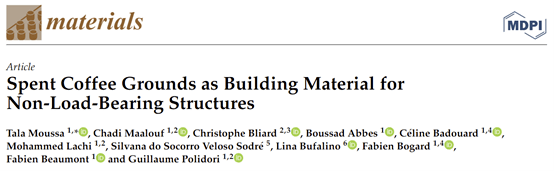

Particle size determination of coffee grounds SCG

Used coffee grounds (SCG) were collected from various restaurants in Reims (France) and immediately dried in an oven at 70°C for several days to remove excess moisture. The particle size of the dried SCG was determined through a series of 1 to 0.25 mm sieves (Figure 1).

Figure 1 Grading curve of SCG

As seen in Figure 1, the coffee grounds samples have D60 = 0.73 mm, D30 = 0.58 mm and D10 = 0.29 mm, uniformity coefficient Cu = 2.5 and curvature coefficient Cc = 1.6. It was shown that the SCG samples used in this study had a uniform and compact grain size, with the major grain sizes ranging between 0.3 and 0.8 mm. The rough surface of the coffee grounds grains provided good adhesion to the starch binder.

Preparation of coffee grounds composite SSCC

The starch used in this study was from potato. Several compositions were tested by varying the proportion of starch (the binder of the composite). The brittleness of SCG composites (SSCC) is too high at starch contents below 40%, which prevents them from being used as insulation materials in the construction field. Therefore, two extreme formulations were prepared to study the performance of the composites, namely a starch ratio of 0.4 (SSCC-40 brittleness limit) and 1 (SSCC-100 starch only).

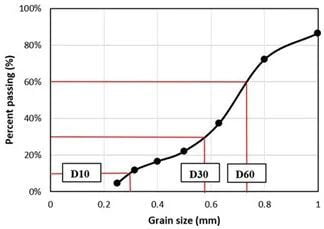

Mechanical properties of SSCC

Although the mechanical performance requirements are not as high for construction materials of non-load-bearing structures, it is still necessary to ensure that the material can support the weight of the elements above it without collapsing.

Figure 2 Compressive strain-stress curves of SSCC-100 and SSCC-40 samples

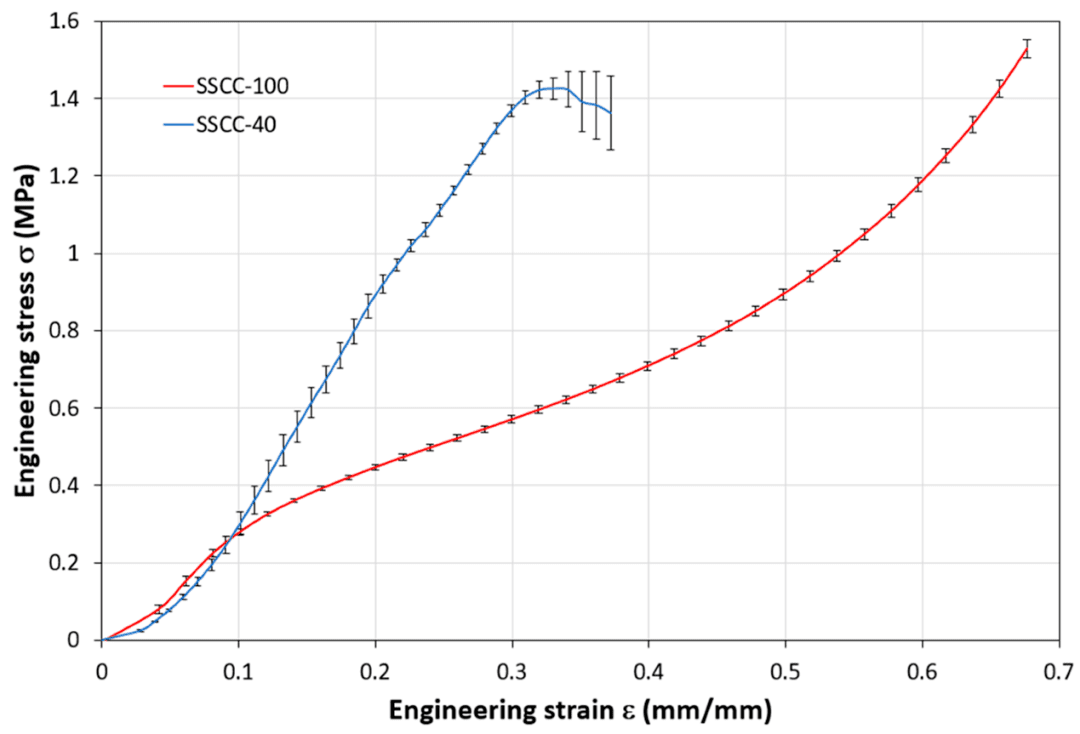

Figure 3 Cube shape before and after compression test SSCC-100 ( a ) and SSCC-40 ( b )

The modulus of compression can be used as a measure of the stiffness of a material or the ability of a material to withstand changes in length when subjected to a compressive load. The higher the modulus of compression, the stiffer the material. The results show that Young's modulus increases with decreasing starch content. For the starch samples, this value was about 3.38 MPa, while SSCC-40 increased to 6.09 MPa. given the rigidity and mechanical properties of this composite, it is possible to create self-supporting walls. Construction of SSCC-40 brick walls to fill the space inside the timber frame, for example, each brick can support the load of the above brick wall. In the case of hollow bricks, the Young's modulus is improved while the weight is reduced.

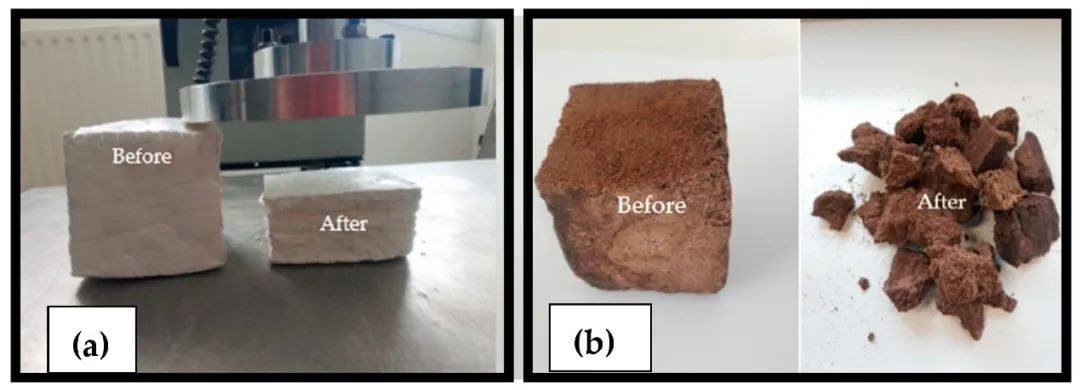

Figure 4 Example of a fully hollow SSCC-40 brick (220 × 100 × 60 mm3)

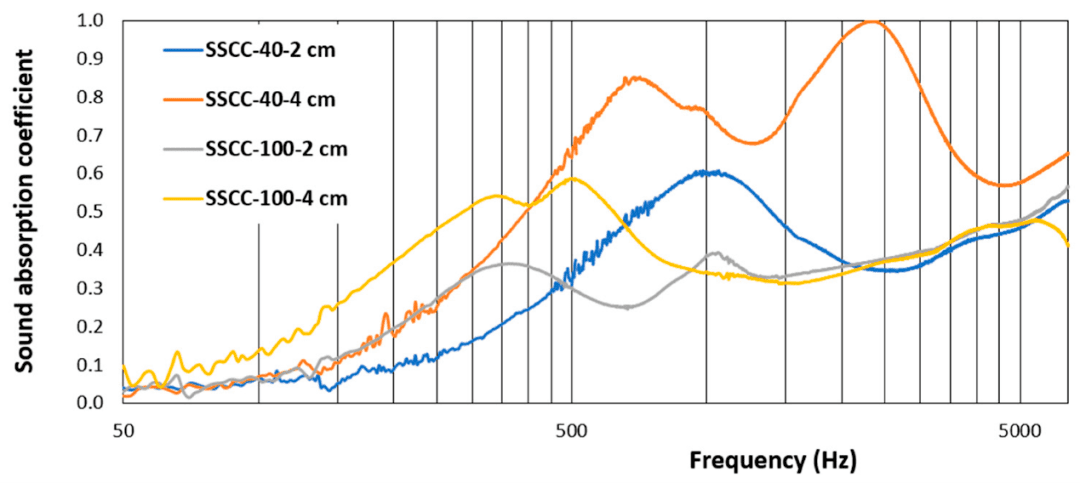

The absorption coefficient is used to evaluate the sound absorption efficiency of a material. It is the ratio of absorbed energy to incident energy and is expressed as α. If the sound energy can be completely absorbed, then α = 1. The absorption coefficients of the SSCC-100 and SSCC-40 samples are shown in Figure 5, as α also depends on the type of adhesive, the porosity structure, and the distribution of pores in the sample.

Figure 5 Sound absorption coefficients of starch and SSCC-40 for 2cm and 4cm thicknesses

Summary

In this study, the authors explore a practical method for upcycling waste coffee grounds SCG for reuse as insulation in the construction industry. This new biocomposite material is associated with a plant-based binder derived from potato starch and is intended as a sustainable alternative to mineral or petroleum-based compounds for construction materials.