Recently, researchers at three institutions - the U.S. Department of Energy's National Renewable Energy Laboratory (NREL), Massachusetts Institute of Technology (MIT) and Washington State University - reported success in using lignin, the rigid part that makes up the cell walls of plants, as a way to achieve 100 percent sustainable aviation fuel. Other parts of the plant are used to make biofuels, but lignin has been largely neglected because of its difficulty in chemically breaking down and converting it into useful products.

The newly published study demonstrates a process developed by researchers to remove oxygen from lignin so that the resulting hydrocarbons can be used as a feedstock for jet fuel blends. The study, entitled "Continuous hydrodeoxygenation of lignin to jet range aromatics," was published in the journal Joule.

Gregg Beckham and Earl Christensen are researchers from NREL.

The paper points to the need for sustainable sources of aviation fuel as the aviation industry has committed to significant reductions in carbon emissions.

In 2019, airlines consumed 106 billion gallons of jet fuel worldwide, and that number is expected to more than double by 2050.Achieving the industry's goal of achieving net carbon neutrality over the same period will require large-scale deployment of sustainable aviation fuels (SAF) with high blending limits with conventional fuels.

Jet fuel is a mixture of different hydrocarbon molecules, including aromatics and cycloalkanes. Current commercial technology cannot produce components that meet 100% SAF conditions. Instead, SAF blended feedstocks are used in combination with conventional hydrocarbon fuels. As nature's largest source of renewable aromatics, lignin can solve the problem of achieving a fully bio-based jet fuel. This newly published work illustrates the ability of the lignin pathway to complement existing pathways and other developmental pathways. Specifically, the lignin pathway described in this new work allows SAF to be fuel system compatible at higher mixing ratios.

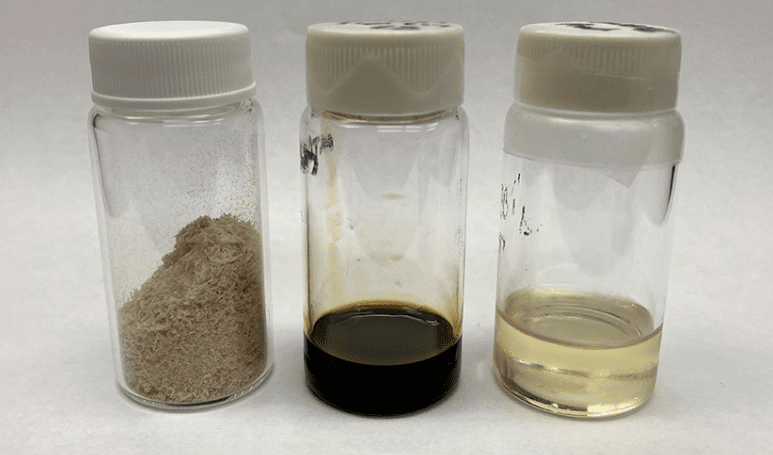

Because of its inertness, lignin is typically used for heating and power generation, or only for low-value applications. Previous studies have produced lignin oils with high oxygen content of 27% to 34%, but to be used as jet fuel, this amount must be reduced to less than 0.5%. Other methods have been tried to reduce the oxygen content, but the catalysts involved require expensive precious metals and have proven to be low yielding. Researchers at the three institutions demonstrated an effective method that uses earth-abundant molybdenum carbide as a catalyst to achieve an oxygen content of about 1 percent in a continuous process.

The U.S. Department of Energy's Office of Bioenergy Technologies and the Bioenergy Innovation Center funded the research.

NREL is the primary national laboratory for renewable energy and energy efficiency research and development for the U.S. Department of Energy. NREL is operated for DOE by the Sustainable Energy Alliance, LLC.