By adding a naturally occurring polymer that makes the wood more porous, the scientists designed the trees to be easier to disassemble into simpler building blocks.

Fossil fuels are a major source of energy, chemicals and many materials, but are also responsible for a significant portion of greenhouse gas emissions. In order to become carbon neutral, most of the products made from fossil fuels today will have to be made from biomass tomorrow. Plant feedstocks have been investigated as the demand for sustainable materials and renewable energy continues to grow, but converting woody plant biomass into fuels and other useful products is chemically and energetically demanding.

Until today, research to understand how woody biomass can be altered to increase the efficiency of its conversion to simpler components has focused on the complex polymers already present in wood.

Dr. Bourdon, a former researcher at the Sainsbury Laboratory at the University of Cambridge (SLCU) and now at the Friedrich Mitscher Institute for Biomedical Research, and colleagues took a different route.

They took callus, a polymer that occurs naturally in the cell walls of some plants, and successfully transformed it into wood, a secondary cell wall unique to plants. The study, published in the journal Nature Plants, involved an international collaboration across multiple institutions and showed that callus-rich wood is more easily converted to simple sugars and bioethanol than non-engineered wood.

The team first turned the small model plant Arabidopsis ( Arabidopsis thaliana ) to biosynthesize callose in its secondary walls. He showed that plants can accommodate new polymers in their secondary cell walls without any negative impact on growth."

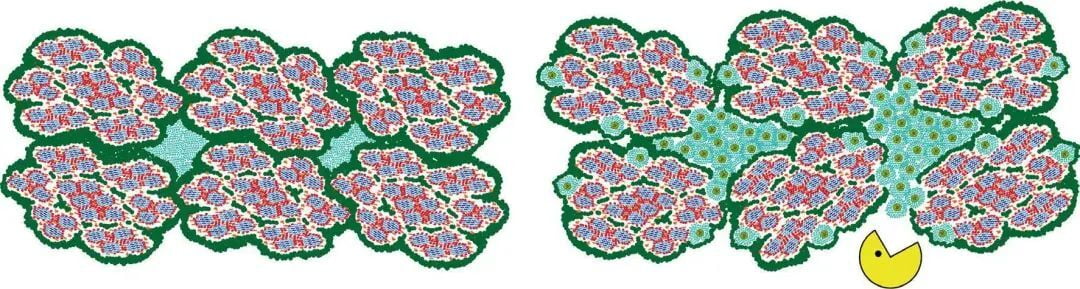

Models of poplar macrophyte fiber assembly without callus deposition (left) and with callus deposition (right). Callose self-aggregates between large protofibers, which explains the observed increase in secondary cell wall porosity. The affected pore sizes ranged from 4-30 nm, which is within the pore size range of the hydrolases. Thus, callus is thought to act as a hydrophilic spacer for secondary cell wall polymers, further facilitating the entry of hydrolases for subsequent saccharification. (Figure originally published in Bourdon et al, 2023 Nature Plants.

Transforming tree engineering into a more efficient and sustainable feedstock for biomass conversion

Switching to a fast-growing tree, the deciduous hybrid aspen (Populus tremula x tremuloides), the team found that the callus-rich wood exhibited interesting new properties, such as increased hygroscopicity and porosity, which made the polymers easier to extract and convert into simpler building blocks, such as sugar or bioethanol.

Understanding the effect of added callus on the ultrastructure of engineered wood is very challenging, and the cutting-edge experiments carried out by Paul and Ray Dupree's team at the Universities of Cambridge and Warwick are the cornerstone of this research," said Dr. Bourdon.

In fact, they surprisingly found that callose does not interact with other polymers, but showed that callose can act as a cell wall spacer that attracts water. This approach has inspired us to look for answers beyond our own expertise and to establish further collaborations to carry out this multidisciplinary research, ranging from genetic engineering, biochemistry, structural biology to materials science."

"We anticipate that our engineered wood will benefit the production of biomaterials and biofuels dependent on biomass deconstruction and polymer accessibility, such as packaging materials, and even advanced biomaterials such as cellulose nanofibers and delignified wood. The next step is to conduct field trials to confirm our findings and evaluate the performance of callose-rich trees under real forestry conditions. We also hope that the discovery of introducing a new polymer into wood will inspire other researchers to introduce other types of polymers for customized applications."