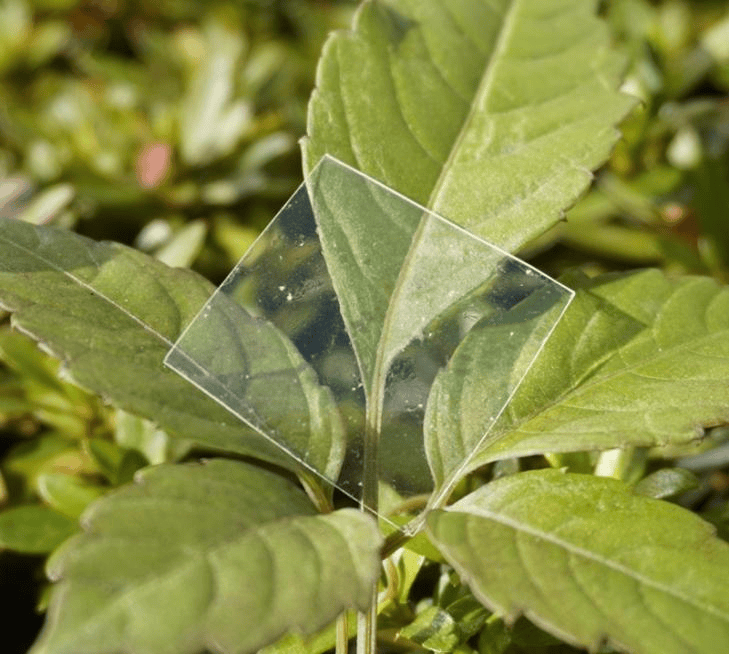

Researchers led by Professor Takuzo Aida of the Center for Advanced Materials Science (CEMS) at the RIKEN Research Institute in Saitama, Japan, have developed a durable plastic that does not contribute to microplastic pollution in the ocean.

The new material is as strong and biodegradable as traditional plastics, but what makes it special is that it breaks down in seawater. As a result, the new plastic is expected to help reduce harmful microplastic pollution that accumulates in the oceans and soil and eventually enters the food chain. The results of the experiment were published Nov. 22 in the journal Science.

Scientists have been working to develop safe and sustainable materials to replace traditional plastics, which are unsustainable and harmful to the environment. While some recyclable and biodegradable plastics already exist, a major problem remains.

Currently biodegradable plastics like polylactic acid (PLA) often find their way into the oceans, where they cannot degrade because they are insoluble in water. As a result, microplastics (pieces of plastic smaller than 5 millimeters) are harming aquatic life and entering the food chain, including our bodies.

In their new study, Aida and her team addressed this problem using supramolecular plastics, which are polymers that link structures together through reversible interactions. The new plastic is made by combining two ionic monomers that form cross-linked salt bridges, which give the material its strength and flexibility. In preliminary tests, one of the monomers was sodium hexametaphosphate, a common food additive, and the other was a monomer of several guanidinium salt cations. Both monomers are metabolized by bacteria, ensuring that the plastic is biodegradable when broken down into its constituent parts.

Key Breakthrough: Salt Bridge Structures and Controlled Degradation

Aida said, “It has long been assumed that the reversibility of chemical bonds in supramolecular plastics would make them fragile and unstable, but the new material we have developed is just the opposite.” In this new material, the salt-bridge structure is irreversible unless exposed to an electrolyte environment like that contained in seawater. The key discovery lies in how to make these selectively irreversible cross-linked structures.

As with oil and water, the researchers mixed the two monomers in water and observed the appearance of two separate liquids. One liquid was thick and viscous and contained cross-linked salt bridges that form important structures, while the other was watery and contained salt ions. For example, when sodium hexametaphosphate and alkyl diguanide sulfates are used, the sodium sulfate salt is drained into the aqueous layer. The final plastic, alkyl SP, is made by drying the remaining material from the thick viscous liquid layer.

The “desalination” step proved to be critical; without it, the final dried material would be a fragile crystal that could not be used. By re-salting the plastic in brine, the cross-linked structure is rapidly deconstructed and completely disintegrated within a few hours. Thus, having created a plastic that is strong and durable and still dissolves under certain conditions, the researchers next tested the qualities of the plastic.

Key discovery: reshaping supramolecular polymers

The new plastic is non-toxic and non-flammable - meaning no carbon dioxide emissions - and can be reshaped at temperatures above 120°C like other thermoplastics. By testing different types of guanidinium sulfate, the team was able to create plastics with varying hardness and tensile strength, properties that are comparable to or even better than traditional plastics. This means that this new type of plastic can be customized on demand; hard, abrasion-resistant plastics, rubbery silicone-like plastics, plastics with high load-bearing capacity, or low-tensile flexible plastics are all possible. The researchers have also created ocean-degradable plastics using polysaccharides that can form cross-linked salt bridges with guanidine monomers. Such plastics could be used for 3D printing as well as medical or health-related applications.

A new family of plastics: recycling and the environment at the same time

Finally, the researchers investigated the recyclability and biodegradability of the new plastic. After initially dissolving the new plastic in salt water, they were able to recover 91% of the sodium hexametaphosphate and 82% of the guanidine in powder form, suggesting that the recycling process is easy and efficient. In soil, the new plastic flakes degraded completely in 10 days, acting as a fertilizer to provide phosphorus and nitrogen to the soil.

Says Aida, “With this new material, we have created a new family of plastics that are strong, stable, recyclable, multifunctional and, importantly, do not produce microplastics.”