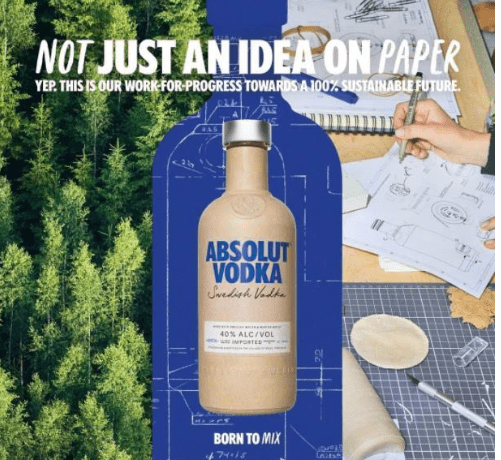

Recently, Absolut Vodka announced that it will be launching a single-mode paper bottle* in the UK, which is made of 57% paper with a thin layer of recyclable plastic attached to the outer layer that prevents liquid leakage, in addition to being eight times lighter overall than a standard glass bottle, making it easier to carry.

The product will be available in Tesco stores in the Manchester area this summer and will retail for £16.

Stéphanie Durroux, Absolut's Chairman and CEO, said, "This is an important milestone in Absolut Vodka's journey to become a carbon-neutral product by 2030. However, it is not perfect and we will continue to refine it until it becomes 100% bio-based and recyclable."

Back in 2019, Absolut Vodka was reported to have started a partnership about paper bottles with paper bottle company Paboco, a joint venture between renewable materials company BillerudKorsnäs and plastic bottle manufacturing specialist Alpla. Understand that Carlsberg launched the world's first prototype of a beer bottle made from recyclable and bio-based materials that year and wanted to commercialize a 100% bio-based bottle without polymers, and it was this move that led to the formation of the paper bottle company Paboco.

Paboco launched a paper bottle community the day it was founded. Absolut Vodka was one of the founding pioneers of this community, which has since been joined by companies such as Coca-Cola, L'Oréal and Carlsberg, in a bid to work together to drive the beverage and packaging industry towards sustainable packaging.

Then in 2020, Absolut Vodka is conducting trials of 2,000 paper bottle prototypes in Sweden and the UK to test the viability of paper packaging as an alternative to single-use plastics in beverage applications. Absolut Vodka says the paper bottle is the first physical product of their Future Packaging Program, which hopes to use sustainable materials to make bottles that have less of an impact on the environment. Its packaging development is guided by the three key principles of sustainability, consumer delight and sociability, and uses the TLO concept of 'Test, Learn and Optimize' in its actual development, through which the team receives regular feedback throughout the process to ensure that the packaging is fit for its intended purpose. The launch of this single-mode paper bottle marks the first time Absolut Vodka will be the first global spirits brand to commercially sell a single-mode paper bottle in the UK.

1 Exploring the commercialization of Absolut Vodka's single-mode paper bottles

There are several paper bottle forms on the market featuring two mechanically interlocking half shells designed to fit around the liner of a filled liquid product. Buen Vato Tequila, for example, uses the Frugal Bottle concept from Frugalpac in the UK. A few years ago, Seed Phytonutrients was one of the brands Ecologic Brands piloted in the U.S. in the form of shampoo and conditioner eco.bottle. Advantages of this design include the ability to save space during transportation and avoid "shipping air" until the two halves are joined during packaging.

But from the early iterations to the first commercial release, Pabaco and the Absolut Vodka program have always relied on a single-molded design, said Tim Silberman, Paboco's chief technology officer, "It's always been one-piece molded, and that's what makes our products so strong, durable and liquid-friendly."

"Using single-mode technology provides the best characteristics for our paper bottles. We need to protect the goods inside, and this can be achieved by manufacturing the bottle as a single item - no glues, no hinges, no flaps to hold multiple parts together," adds Eric Naff, Director of Packaging Development at Absolut Vodka. "In addition, the process is much more efficient that way. We don't need any additional steps to assemble the two shells, and by molding the bottles in one piece, we can improve energy and process efficiency."

The pulp used in these bottles is exclusively Forest Stewardship Council (FSC) certified material. No recycled materials are used in these bottles to avoid encountering food safety and material traceability issues. Silberman said, "Using fresh virgin fibers gives us the best performance in terms of important factors such as strength and is the benchmark for us to achieve our vision of a fully bio-based bottle. We can only develop a new generation of paper bottles and barrier materials if the paper itself has the necessary properties."

Silberman says, "We use a thin bottle blank that is blown into the bottle to create a barrier layer, which also results in a controlled bottle neck effect." To complete the paper bottle, a plastic barrier layer is blown inside the paper shell and separated from the molded material. It's worth noting that the barrier liner is stiffer than the flexible material-it's especially stiff in the neck area, which is needed to close and seal the bottle properly, and the finish, including the threads, is part of the internal barrier layer of the first-generation bottles.

Despite its rigidity, the liner is thin and provides no structural support. Instead, all structural support comes from paper. Paper is the foundation and will continue to be as we work toward our vision of a fully bio-based bottle," Silberman says. But by applying a plastic barrier layer to the bottle in the second step, we can separate the strength properties of the paper bottle from the barrier properties of the liner. Since we used only mechanical interlocks in the first generation of barrier applications, the materials can be easily separated."

The first generation of bottles used a polyethylene naphthalene dicarboxylate (PEN) barrier, a single material with strong barrier properties that can be recycled in small proportions with the closely related polyethylene terephthalate (PET). The PEN material was chosen for its properties and tolerance/compatibility with Absolut Vodka. Post-consumer recovery (PCR) materials can be selected for general applications, but not for high alcohol content (ABV), not just low ABV ready-to-drink (RTD) options.

"This version of the paper bottle was improved for 40% ABV Absolut Vodka and the challenge of maintaining a higher alcohol content than 5% Mixt," says Naff, "40% ABV is challenging for many materials and therefore requires thorough testing. The barrier layer in the first generation of paper bottles applies to Absolut Original Vodka. the next generation of bottles will go through the same testing and approval process before release, and the next version of the paper bottles will not be able to hold the carbonated product, making Absolut Original Vodka the logical choice for this test."

Decorating requires applying digitally printed labels to filled, capped bottles. Consumers do not need to remove the labels before recycling because they are also printed on recyclable materials. "The technology does not yet support scalable printing on paper bottles. But label application is not an issue at all because it is done on filled bottles," says Naff.

Additionally, previous generations of Absolut Vodka paper bottles have experimented with paper caps from Blue Ocean Closures (BOC), but since the Blue Ocean Fiber Cap is still under development and not yet a commercial option, the first generation of paper bottles used standard Absolut Vodka caps made of lined plastic with an aluminum shell.

While the standard glass bottles are also recyclable, the paper bottles are eight times lighter and, allegedly, easier to carry. Nonetheless, their ultimate goal is to complement Absolut Vodka's iconic glass bottle, not replace it. Absolut Vodka believes consumers will use the paper bottles in outdoor settings such as festivals, parks or beaches.

The trial is specifically designed to gain insights from consumers, retailers and supply chain partners to inform the next steps in Absolute Vodka's innovation journey towards a commercially viable, fully bio-based bottle. Absolut Vodka will test how the paper bottle is transported and how it is perceived by consumers.

It also said that this represents an important milestone in Absolut Vodka's journey to become a carbon neutral product by 2030, and that a prerequisite for being able to achieve this is to reduce the carbon footprint of its packaging. According to a Beverage Industry Environmental Roundtable (BIER) benchmarking study based on 2020 data, Absolut Vodka says it expects to be carbon neutral by 2030, with its distilleries emitting 98% less than the average distillery. Last November, it announced the initiative with the Ade Glass Packaging Group to begin large-scale bottle production using partially hydrogen-fired glass furnaces.

2 Paper bottles are currently realized by three technical means

1、 two pieces of pulp molding bottle embryo with an ultra-thin biodegradable plastic liner, this technology is now more mature, there are more cases on the market.

2、 Re-sharing a one-piece molded paper bottle packaging of Carlsberg beer with a biodegradable plastic barrier liner

Teknos has worked with major international brands such as Coca-Cola, Carlsberg, L'Oréal and others, and with materials, design and technology experts to develop landmark paper bottles that do not require the use of a plastic layer as a barrier, but instead use a water-based dispersant that prevents water or grease from seeping into the paper. This technology makes it easier to achieve full degradation. In fact Carlsberg launched two identical paper bottles in October 2019, one with a biodegradable plastic liner and the other with a TEKNOS coated liner solution. Teknos is committed to contributing to shaping a sustainable future. Recently, Teknos has introduced newly developed and completely bio-based coatings that contribute to the recyclability of bottles and cans. Teknos has played a key role in working with major international brands such as Coca-Cola, Carlsberg, L'Oréal and in developing landmark paper bottles with materials, design and technology experts.

The packaging and food service industries are undergoing profound changes. Consumers and the packaging industry have been looking for more sustainable, recyclable solutions and alternatives to replace or minimize traditional plastic packaging.Teknos is addressing this need by developing coatings for the food packaging industry.

"Teknos has a long history of developing functional coatings for a variety of surfaces and materials. It was natural to wonder if this technology could be applied beyond traditional coating uses. Tuomas Aspiala, Commercial Manager at Technos Group, says: "Traditionally, paper and cardboard used in food packaging are covered by a layer of plastic film, but there is an alternative: aqueous dispersants prevent water or grease from penetrating into the paper and are ideal for food packaging."

Innovation is at the heart of the company's development. "Teknos is always looking for innovative solutions for its customers, partners and changing needs. Collaboration with business partners is vital for innovative ideas. That's why Teknos has been able to come up with something truly unique and meaningful to make life on Earth last longer." Aspiala added.

On October 11, 2019, at the C40 Global Mayors Summit in Copenhagen, Carlsberg, the world's fourth largest brewing group, presented 2 prototypes of green fiber bottles carrying beer, for the first time to the world. It's the two ways mentioned above.

3 From concept to reality, paper can also be environmentally friendly

For the development of paper bottles, production of technology, raw materials and "paper bottle community" project to facilitate and promote the issue, we interviewed the Swedish paper materials company BillerudKorsnäs China cardboard business development director, the current president of the Packaging House, Mr. Zheng Jian, around the environmental protection, combined with the reality of the Nordic paper industry, to get further answers.

1、Tripartite experts unite for environmental protection and jointly promote sustainable packaging

In 2015, Carlsberg, in conjunction with innovative packaging company EcoXpac, paper packaging material company BillerudKorsnäs and post-doctoral researchers at the Technical University of Denmark, began material testing and bottle design for wood fiber paper bottles using a new production process and strength.

Considering the feasibility and on-the-ground product application, it is necessary to test through more representative brand parties in the industry. At the same time, through the brand side, to get closer to the market and effective suggestions.

In March 2019, paper-based materials company BillerudKorsnäs entered into a strategic partnership with packaging bottle manufacturer ALPLA, focusing on solving compartmentalization issues such as water and oxygen barrier in bottles, accelerating the project's progress.

On September 25, 2019, BillerudKorsnäs and ALPLA formed a joint venture, Paboco® (Paper Bottle Company), with a straightforward naming that expresses the dedication and commitment to the development of paper bottles. In October, Paboco® set up a "Paper Bottle Community" with Carlsberg, Coca-Cola, Absolut Vodka and L'Oréal to promote the development and market introduction of sustainable packaging.

So far, gathering paper experts, packaging bottle manufacturing experts, and industry product experts who fit together on the SDGs, 4 brand groups covering the beverage, beer, spirits, and cosmetic sectors have provided first-hand information on the R&D and testing of paper bottles from the 2 suppliers in terms of bottle usage, packaging needs, and cost ranges.

2、From sustainable forests to non-polluting production, papermaking can also be environmentally friendly

Plastic bottles, aluminum cans, glass bottles and other packaging on the market cannot be naturally degraded and need to consume more carbon footprints to be recycled, and if the recycling is unfavorable, it will become a hidden danger that damages the ecological environment. The goal of the "Paper Bottle Community" is to achieve 100% environmental protection by allowing consumers to naturally degrade paper bottles after use, even if they are thrown into the sea or the natural environment, and to be naturally absorbed after decomposition. Of the 2 newly released wood fiber beer bottle compartments, one utilizes recycled PET polymer film rather than virgin PET, again for sustainability reasons and to ensure a more environmentally friendly material in every part. The other has a 100% bio-based PEF polymer compartment that is 100% biodegradable.

While wood is continuously exported through human management, forests of increasing size will absorb more carbon dioxide and emit more oxygen, realizing a virtuous cycle.