January 1, 2022 France banned the sale of fruits and vegetables in plastic packaging weighing less than 1.5 kg, involving 30 types of fruits and vegetables, including bananas, pears, lemons, bell peppers, cucumbers and carrots. In 2026, the ban will be extended to all fruits and vegetables.

It is estimated that about 37 percent of fruits and vegetables are packaged in France, and the new law encourages the use of reusable bags, which could prevent the use of at least one billion plastic packages each year.

After plastic packaging was banned (including bioplastics), only packaging materials such as paper bags were left to be used. However, compared to plastic packaging, paper packaging is poor in barrier and water resistance, and the performance needs to continue to improve. The EU does not allow the use of biodegradable plastics, so what do they use?

Recently, the Swiss Federal Laboratories for Materials Science and Technology (EMPA) and Lidl Switzerland developed an ecological nanofiber film coating for bananas that avoids plastic packaging and effectively extends the shelf life of the fruit by simply coating the bananas with a cellulose film to keep them fresh.

After a year of research and development, EMPA researchers created a protective fruit and vegetable coating using completely renewable raw materials.

1. Extended shelf life

EMPA's cellulose coating ensures the freshness of fruits and vegetables, keeping them fresh for "significantly longer" than uncoated products. "

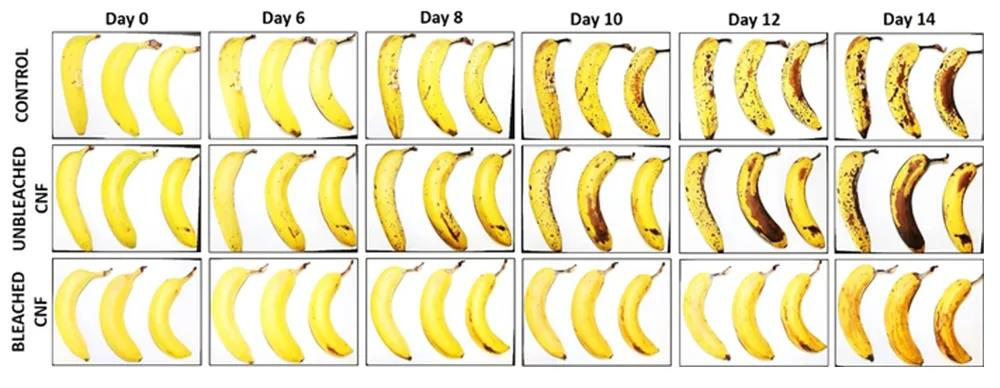

In the tests, the shelf life of bananas, for example, was extended by more than a week. This significantly reduces food waste," says Gustav Nyström, head of Empa Labs.

Bananas with and without EMPA coating in shelf-life tests

According to the survey, 60 percent of global consumers are willing to sacrifice shelf life to reduce plastic packaging, and 56 percent are willing to sacrifice product protection to reduce the amount of plastic used in packaging. However, market researchers also say that more than half (64%) of global consumers believe that it is good for products to be more environmentally sustainable, but that packaging performance should not be compromised.

Nyström says, "Our main goal is that this bio-coating will be able to replace a lot of petroleum-based packaging in the future."

2. Production process

The production of the coating consists of processing the "pomace" into raw fibrillated cellulose. "Fruit pomace is the solid residue left after extracting the juice from a fruit, vegetable or plant," Nyström explains.

Traditionally, he says, this plant "residue" is disposed of in biogas plants or directly in the field, but in the future it will be used to make protective coatings for fruits and vegetables. The protective nanofiber film is sprayed on the product and, because it is harmless to consumers, the solution can be washed off before consumption.

This new technology will be used in all Lidl Switzerland stores. In the meantime, Nyström says the potential of the cellulose coating has not yet been fully realized. "There is the possibility of adding additives such as vitamins or antioxidants," he added.

3. Switzerland

An initial product study starting in 2019 has now been "successfully" completed, and EMPA's cellulose layer will be tested and improved over the next two years. The study involves a collaboration with Lidl Switzerland and is supported by Innosuisse (Swiss Innovation Agency).

Nyström confirms, "Our goal is to use the new technology in all 150 Lidl stores in Switzerland after a successful main trial." On a related note, Sufresca, based in Israel, has developed edible coatings for fruits and vegetables that eliminate plastic packaging from fresh produce and reduce food loss and waste. Black technology! Israeli startup: Apply this coating and the fruit stays fresh and ready to eat!

Meanwhile, Morrisons will be the first UK supermarket to remove plastic banana bags from its shelves as part of a 50% reduction in own-brand primary plastic packaging by 2025.