Natural PHA materials can be used in traditional plastic applications such as thermoplastics, thermosets, elastomers, lubricants, gums and adhesives, as well as in some non-traditional polymer applications such as animal feed, cell regeneration for humans and animals, denitrification and cosmetics.

We believe that natural PHA materials demonstrate their tremendous versatility in application, outperforming any other available materials. The reason for this is that natural PHA materials exist in many parts of nature and have even been around for far longer than humans.

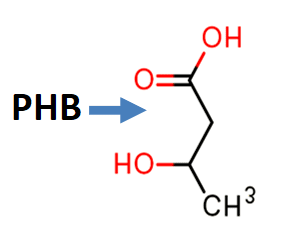

PHA stands for polyhydroxy fatty acid esters, which can have an infinite number of different moieties. Thus, it is meaningless for us to state the nature of PHA directly, because different molecules have different properties.

Eco-friendly straws

However, many PHA materials are naturally occurring, such as PHB and some of its copolymers, such as PHBV, PHBHHx, P3HB4HB, PHBO and PHBD. these materials are not synthetic plastics, but are natural materials found in nature, like cellulose or starch.

These natural macromolecules are not produced by chemical polymerization, but by the conversion of natural nutrients (sugars, vegetable oils, starch, etc.) through enzyme-controlled biochemical reactions.

PHB powder and granules

These natural PHAs are part of the metabolism of all living organisms (including plants, animals and humans) since the beginning of life on earth. They are nutrient and energy storage materials. Naturally we can think of them as biodegradable materials or as feed for living organisms in various environments. Moreover, unlike most other materials, they can be fully satisfied with various forms of end-processing.

Today, these biologically benign materials are produced even by industrial scale, though only to mimic natural synthetic pathways. There are many capacity expansions planned or underway, particularly in the Asia-Pacific region and North America. These materials can be used in thermoplastics, thermosets, elastomers, lubricants, gums, and adhesives, as well as in some non-traditional polymer applications such as animal feed, human and animal cell regeneration, denitrification, and cosmetics.

PHB monomer is 3-hydroxybutyric acid

Over the past decade, many companies have invested billions of dollars in the development and construction to utilize industrial mass production of natural PHA materials. At the same time, many applications have been developed, mainly focused on those focusing on biodegradability and high added value.

In fact, natural PHA substances are forage for organisms in various environments and therefore they are capable of biodegradation (i.e., conversion of carbon to carbon dioxide gas) in various environments, although the rate of biodegradation depends on geometry and external conditions such as temperature, humidity and others.

At the request of the German Federal Ministry of Food and Agriculture, the results of the BioSinn project describe a portfolio of 25 market products for which biodegradability is a viable treatment outcome. Biodegradability shows its advantages, for example, when it is difficult or even impossible to separate plastics from organic materials for home or industrial composting, when it is necessary to avoid plastic debris entering the open environment, or when their removal is difficult or costly.

Products currently on the market with natural PHA materials include coffee capsules, garbage bags, clips, nonwovens, food packaging films, microplastics in cosmetics, and coated paper in coffee cups. Among them, coated paper can also be recycled by the paper industry. In addition to this the BioSinn report also mentions many application possibilities. All in all the biggest challenge at the moment is the total global productivity of natural PHAs, and many new plants are being built.

Plastic pollution

Of course biodegradability is not the only unique selling point of PHA (USP), one consortium has made it clear that they have significantly upgraded their company's scientific research to develop natural PHA materials. They have developed new PHA compounds that are 100% bio-based, resistant to high temperatures, easy to process, and can be customized into a variety of durable products.

The compounding company has developed more than 500 different natural PHA-based formulations ranging from rigid to extremely flexible, resistant to high temperatures up to 130°C, weather and UV resistant, melt fast nucleation, and improved barrier properties, demonstrating that natural PHA materials can be converted into a range of new biopolymers that can be processed as fast or faster than all conversion technology polymers used in the industry today.

Not only that, PHAs are already available as a main component in thin films or 3D printing, whereas a few years ago they were often used as additives together with PBAT or PLA. The tunability of high molecular weight non-crystalline or low crystallinity PHA grades (e.g. 50% 4HB for P3HB4HB or 30% Hx for PHBHHx) allows us to change the properties, the attributes of the polymer.

These examples are not just theoretical and have been used in products such as eyeglass cases (replacing ABS or PP talc), pens (replacing ABS), design chairs (replacing GFR-PP), lamps, and light switches (replacing PC/ABS).

PHA Products

In addition, a number of low E-modulus natural PHA materials have been developed for use in hot melt adhesives, pressure sensitive adhesives, laminating adhesives and sealants. So far, the use has been less widespread due to low production volumes, but it is only a matter of time. Several materials have been used as plasters in coatings to replace silica for better transparency and haptic properties (soft feel). These tactile properties are one of the unique selling points of these materials.

Finally, due to the large amount of plastic entering our oceans every year, many people are actively involved in the development of textile and nonwoven fibers made from PHA. Although the first applications have appeared in the market, they are still small and the development of applications is still in its early stages, especially for textile applications. The fibers currently available in this market for textile applications contain other polymers in addition to the natural PHA material.

PHA fiber spinning

Given the role of natural PHA materials in the natural environment and their appearance, a number of non-traditional plastic applications have also been developed and commercialized. These include applications in animal feed, healthcare (both human and animal), denitrification, artificial turf and cosmetics.

In specific environments (wastewater treatment, aquariums, shrimp, fish, turtle farms, etc.), denitrification is required when there is too much ammonia. Ammonia is turned into nitrate and nitrite by oxidation. In contrast, natural PHA is an excellent source of carbon for the reduction of nitrate and nitrite to nitrogen. This is because it provides carbon for the denitrification process through biodegradation. Today, materials for these applications are already on the market.

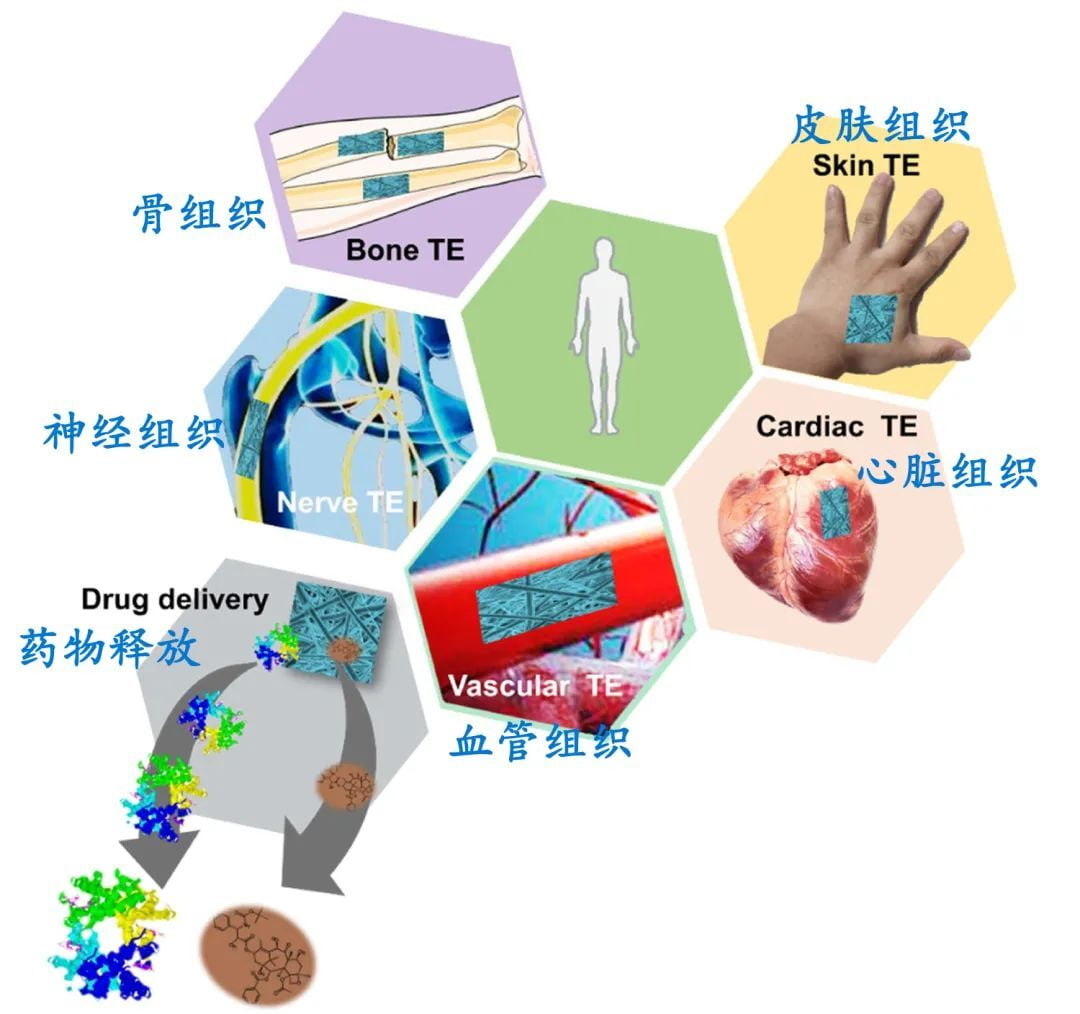

Another completely different application is the use of natural PHA for medical purposes. In the human body, one can use microspheres composed of PHA to contain and culture stem cells. The degradation time of microspheres is about one year and the degradation products are used by cells and help the growth of cells. In addition to this PHA can be used for bone regeneration, skin damage repair (wound closure), nerve guidance catheters, etc. Tepha (USA) has been producing several of these products for about 10 years, and Madefa (China) has also made achievements in this area, one of which is the use of PHA as a carrier to control drug transport delivery.

PHA Medical Applications

Artificial sports fields like soccer fields always need infill. While old car tires would have been used as infill in the past, today it has been eliminated due to health and environmental safety concerns. Today, natural PHA materials are allowed to be used in artificial turf infill (FIFA approved).

In addition to these, PHB and other natural PHA materials can also be used as feed or feed additives for animals.

Studies on feeding PHB to aquatic organisms have confirmed that PHB has excellent effects on animal growth, gut microbial community structure, and disease resistance, while PHB can be used as an energy source for juvenile European sea bass and helps to increase the lipid content of the whole body.

PHB has also been used as an alternative to antibiotics for protecting shrimp from the pathogenic Vibrio campbellii, and was observed to induce the expression of heat shock protein (Hsp) and to contribute to some extent to the protection of shrimp from Vibrio campbellii, improve growth performance and digestive enzyme activity in shrimp, as well as immune system function in rainbow trout, and improve body weight of Chinese mitten crab larvae.

PHB also improved the survival of roe marsh shrimp larvae, blue mussel larvae, and Nile tilapia larvae.

PHB can affect not only marine organisms, but also large livestock. Feed composition affects the intestinal bacterial community of large livestock and affects their health.

In summary, PHB has no adverse effects on the growth of marine animals such as rhubarb fish and common land animals such as weaned young pigs that are sensitive to food. In the future, plastics made of PHB, possibly including its copolymers PHBV and P3HB4HB, could be used again as feed additives for animals. Better yet, plastics made from natural PHA materials could replace petrochemical plastics to prevent marine or terrestrial animals from accidentally eating plastic packaging waste and dying.

Based on the synthesis and application examples of natural PHA material platform, we believe that this new material platform is like a sleeping giant and has a good prospect.