Plastic waste is a growing problem. The United Nations Environment Programme estimates that 400 million tons of plastic waste are produced globally each year, a figure that is expected to rise to more than 1 billion tons by 2050. Most plastics cannot be recycled and can only be thrown into landfills or incinerated: of the 7 billion tons of plastic waste that has been generated, only about 10 per cent has been recycled.

Many plastics are made from finite, highly polluting petrochemicals. Recently, the U.S. Department of Energy's Lawrence Berkeley Laboratory announced the latest results of its bio-based renewable plastics research - successfully engineered by microorganisms to make poly (diketone ketamine) (PDK), a new type of plastic that can be efficiently and repeatedly recycled, with the resulting paper published in the journal Nature Sustainability, showing that Renewable, recyclable plastics are not only possible, but superior to those made from petrochemicals.

Unlike conventional plastics, PDK can be repeatedly restored to its original, pristine structure and then made into new products without loss of quality.PDKs are initially made with materials derived from petrochemicals, but these components can be re-engineered and produced with microorganisms.

The research team is said to have modified E. coli bacteria so that it can convert sugar from plants into the molecule triacetinolide (TAL) and combine the molecule with other chemicals to produce the new plastic polydiketone enamine (PDK). This new type of plastic contains about 80% biological components, the internal molecular structure is more easily destroyed, and can be 100% recycled and converted. In addition, their flexibility, toughness and even viscosity can be adjusted to meet specific application requirements for the production of adhesives, computer cables, construction materials, etc.

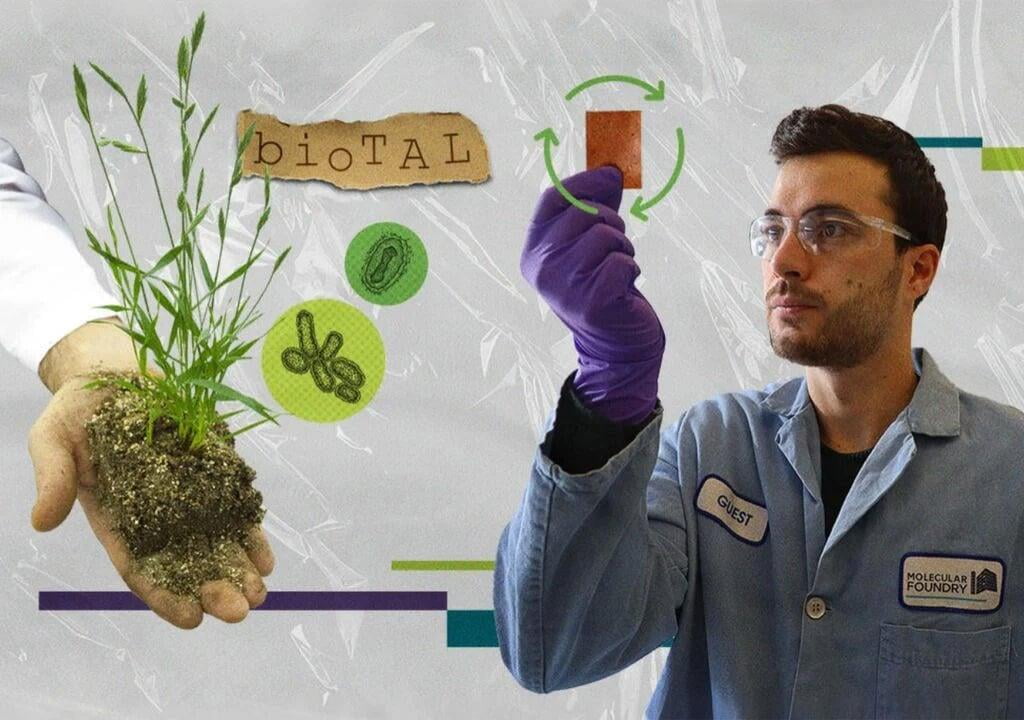

Berkeley Lab researchers use bacteria to bring bio-renewability to recyclable plastics

The researchers describe the bio-based PDK plastic as having an expanded operating temperature range of 60°C compared to the fossil-fuel-based PDK plastic that the lab is launching in 2019, a property that opens up a wider range of potential applications (e.g., sports equipment and automotive parts such as bumpers or instrument panels). He believes that as research continues to make breakthroughs, the biological component will reach 100% of the PDK composition in the future.

The original bio-TAL (left) can be combined with other chemicals and processed into biorenewable, recyclable PDK plastic (right).

"We have found that with modest modifications to existing processes (modifications that may include speeding up the rate at which microbes convert sugar to bioTAL, using bacteria that can convert a wider variety of plant-sourced sugars and other compounds, and powering the facility with renewable energy sources), it will be possible to produce bio-based plastics that are less costly and cleaner than fossil fuel-based PDK plastics, which will become a reality in the near future." Corinne Scown, a researcher on the team, said, "PDK plastics are more commercially competitive than conventional plastics in the context of large-scale production."