1. How are bio-based chemical fibers processed?

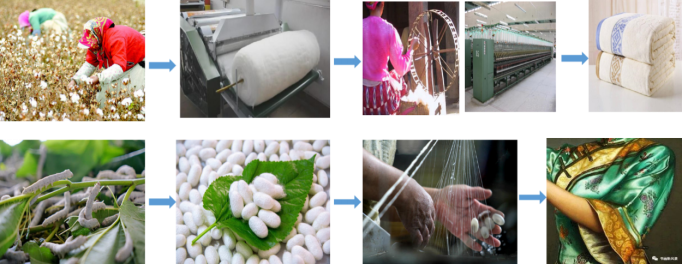

Traditional bio-based primary fibers, or natural fibers, are represented by cotton fiber and mulberry silk. China has been producing cotton fiber and mulberry silk textiles for thousands of years. The term "damask and silk" is used to describe the exquisite and high-grade quality of silk fiber textiles, and in ancient times it was a symbol of power and wealth. Cotton fiber and mulberry silk production is mainly based on cotton and silk as raw materials, mainly through a variety of physical means of preparation and become!

So how are today's bio-based chemical fibers processed and prepared from biomass?

1.1 Processing of bio-based regenerated fibers

Regenerative cellulose fiber, for example, its processing can be roughly divided into cellulose raw material pretreatment processing and fiber molding process two processes:

Cellulose raw material pretreatment processing: cellulose from the raw material can not be used directly, it needs to be purified before the preparation of fiber, purification treatment is the purpose of the raw material in the lignin, hemicellulose and other substances to remove, and then made into pulp (pulping process). Commonly used treatment methods are chemical treatment, mostly using acid and alkali hydrolysis for treatment, but this treatment is more harmful to the environment, has gradually developed a variety of new treatment methods, such as biological treatment (the use of fungi and bacteria to remove lignin, keratin, and other substances), enzyme treatment, physical treatment (the use of mechanical force, high-energy radiation, microwave treatment), steam blasting and so on.

In the beginning, the cellulose needed for fiber production mainly came from cotton and wood, but due to the limitation of arable land and forestry resources, the source of raw materials began to shift to other renewable resources, such as bamboo, hemp, bananas, sugarcane, etc., especially some agricultural by-products, such as sugarcane bagasse, crop residues, coconut shells, etc.... Using these agricultural by-products as raw materials for fibers can turn waste into treasure, reduce product costs, and offer vast possibilities for expanding production.

Fiber Forming Processing: After the pretreatment of fiber raw materials, the next step is fiber forming processing, the spinning technology that has been industrialized is solution spinning, of which the most typical is the viscose method and direct solvent method.

Viscose method is the most widely used cellulose fiber production method, first cellulose with strong alkali treatment to generate alkali cellulose, and then react with carbon disulfide to get sodium cellulose sulfonate, and then the derivative dissolved in strong alkali made of viscose (spinning solution), spinning solution from the nozzle of the fine holes pressed into the sulfuric acid, sodium sulfate, and a small amount of zinc sulfate is made up of the coagulation bath coagulation, regeneration, and then get the man-made fibers after stretching and other processing. The production process contains complex chemical reactions, long process flow, low production efficiency, and the production of CS2, H2S and other exhaust gases, wastewater containing acid, alkali, Zn2+, sludge containing CaO, Al2O3, MgO, Fe2O3, etc., which consumes a large amount of energy, such as water, electricity and coal.

The direct solvent method is represented by the development of new solvent systems represented by N-methylmorpholine-N-oxide (NMMO). NMMO method production process is a kind of cellulose fiber production process without chemical reaction, first of all, the pulp with crystalline water containing NMMO fully mixed, swelling, and then decompression to remove most of the crystalline water, dissolution, the formation of a stable, transparent, viscous spinning stock solution, after filtration, defoaming and spinning. With the advantages of short process, low pollution, good dissolution performance, etc. The regenerated cellulose fiber produced by NMMO method is called "Lyocell fiber" (Lyocell), which is known as the green fiber of the 21st century.

As can be seen from the above, the solvent method can omit a series of chemical treatment processes, shorten the production process and reduce pollution. Researchers in various countries are currently working on the development of other solvent systems.

Other solvents include ionic liquids and low-temperature alkali/urea systems, among which the low-temperature alkali/urea system is a cellulose dissolution system developed independently by China.

Research on cleaner processing of cellulose fibers also includes melt spinning of cellulose esters, i.e., preparation of fiber raw materials by derivatization of biomass raw materials, followed by melt spinning. However, due to the complex chemical structure of natural biomass raw materials, which contain multiple hydroxyl functional groups and are prone to high-temperature degradation, the process has been reported but not yet commercialized.

1.2 Processing of bio-based synthetic fibers

Bio-based synthetic fiber processing and traditional polyester, nylon and other fibers are more similar to the preparation process, are mainly through the melt polymerization to prepare slices, after the melt spinning process to prepare fibers. With the further development of the process, can also develop the melt spinning process.

Taking PLA as an example, the monomer of PLA is lactic acid, or propylene glycol ester prepared by dimer cyclization of lactic acid, which can be obtained by biofermentation from crops such as corn, potato and sugar beet. These crops are produced in large quantities in China, so PLA fibers have great potential for development in China. The production of polylactic acid slices mostly adopts a two-step method, the first lactic acid polycondensation made of oligomers, and then in the role of catalysts made of propylene glycol ester, and then in a vacuum distillation and purification of catalytic ring-opening polycondensation to produce polylactic acid. By further utilizing the chips and through the melt spinning process, a variety of PLA fibers can be produced in various sizes for downstream market applications. Bio-based synthetic fiber processing and traditional polyester, nylon and other fibers are more similar to the preparation process, are prepared through the polymerization of slices, and then melt spinning process to prepare fibers. With the further development of the process, can also develop the melt spinning process.