Bio-based chemical fibers are fibers made from biomass as raw material or polymers containing monomers of biomass origin. The products have the properties of ecological and environmental protection, human body affinity, anti-bacterial comfort, and biodegradability of wastes, etc., and they have been widely used in close-fitting underwear, shirts, hosiery, and home textile products.

1. What are the characteristics of bio-based chemical fibers?

Bio-based chemical fibers have been regarded as "green fibers", "eco-fibers" and "environmentally friendly fibers". So what are the characteristics of bio-based chemical fibers?

Firstly, the raw materials are by-products of plants and animals, which are renewable and can realize sustainable development.

Secondly, bio-based chemical fibers have a low carbon footprint: all or part of the carbon atoms contained in bio-based chemical fibers originate from biomass. In the case of plant biomass, for example, plants absorb CO2 from the earth's atmosphere and use photosynthesis to synthesize new carbon-containing natural macromolecules. After disposal, whether through biodegradation in the environment or combustion to CO2, there is no additional carbon emission from the perspective of the whole life cycle. Therefore, bio-based chemical fibers have the characteristics of overall carbon emission reduction or no carbon emission increase.

Again, most bio-based chemical fibers can present excellent biodegradability and biocompatibility: depending on the specific chemical structure, some bio-based chemical fibers can undergo degradation in compost, natural environments and living organisms, as well as having good biocompatibility for applications such as biomedical applications.

2. What is the relationship between bio-based synthetic fibers and biodegradable fibers?

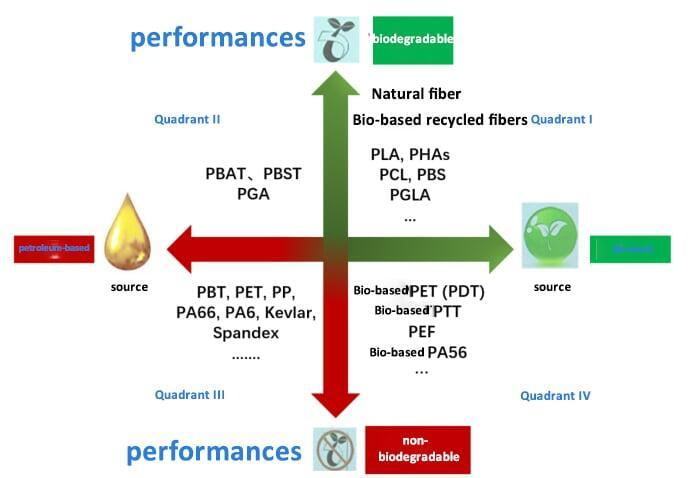

In recent years, the development of biodegradable plastic and fiber products has become particularly important with the global concern over the serious environmental pollution caused by the difficulty of degradation of traditional plastics in the natural environment, as well as the increasingly serious problem of microplastic pollution. In particular, with the gradual implementation of the "plastic ban" in various countries, some products with the potential to cause microplastic pollution will be banned. However, bio-based chemical fibers are mainly those whose raw materials contain renewable plant biomass or animal biomass components, while biodegradable fibers can be derived from both bio-based and petroleum-based sources, thus

Bio-based synthetic fiber ≠ biodegradable fiber

Which bio-based synthetic fibers are also biodegradable?

Which biodegradable fibers are not bio-based synthetic fibers?

Are all petroleum-based polymers or fibers not biodegradable?

In order to answer these questions, we can divide polymer materials or fibers into 4 quadrants according to the source of raw materials and whether they are biodegradable or not, and the main classifications are as follows:

Petroleum-based, non-biodegradable fibers (Quadrant III):

Traditional petroleum-based chemical fibers such as polyester, polyamide, polypropylene and spandex are in this quadrant. These fibers have a high melting point, high crystallinity, regular molecular structure, excellent mechanical properties, and good hydrolysis and chemical resistance, so they degrade very slowly in the natural environment. For example, polyolefins can undergo thermo-oxidative degradation in the natural environment when exposed to sunlight, but the degradation rate is extremely low. The percentage of low-density polyethylene (LDPE) that is converted to CO2 by degradation in 2.5 years is only 0.35%, so we usually consider this type of fiber material to be a non-biodegradable fiber.

Bio-based, biodegradable fibers (Quadrant I):

All bio-based virgin fibers (natural fibers) as well as bio-based regenerated chemical fibers have fully biodegradable fiber products that are more similar to natural biomass because they retain the polysaccharide or protein structure of natural biomass. Bio-based synthetic fibers such as polylactic acid (PLA) and polycaprolactone (PCL), on the other hand, can be composted, as well as neutral enzyme degradation solutions, undergo mass loss, mechanical property degradation and mineralization to small molecules such as carbon dioxide and water, and therefore have better biodegradable properties. Such fibers are eco-friendly fiber materials in terms of full life cycle analysis.

Biobased but hardly biodegradable fibers (Quadrant IV):

The biodegradability of polymer materials is a more complex process, which is closely related to the chemical structure and properties of the materials themselves. Some chemical fiber materials, despite their bio-based properties, are difficult to degrade due to their inherent high crystallinity and excellent thermal properties, which constrain their biodegradation properties, for example:

(1) Bio-based PTT (polypropylene terephthalate) fiber:

The diol monomer used in bioPTT polyesters is biobased 1,3-propanediol (PDO).PDO can be produced biologically from cereals. It is further produced by direct esterification (direct reaction with terephthalic acid and PDO) or transesterification (transesterification of dimethyl terephthalate with PDO). PTT fiber has better resilience performance than other polyester fibers, lower tensile modulus, higher elongation at break; has better dyeing performance; carry crease and soft hand feel. It is a new bio-based fiber variety with international leading position in recent years in China. However, bio-based PTT polyester fiber is closer to polyester and does not have biodegradable properties. Its ecological advantage is that it can effectively reduce the carbon footprint of the product, but it is difficult to be degraded through the natural environment after the product is discarded.

(2) PEF (polyethylene glycol furandicarboxylate) fiber

More similar to bio-based PTT polyester fibers, PEF polyester fibers are prepared using a bio-based dibasic carboxylated monomer, i.e., bio-based furan-2,5-dicarboxylic acid, with ethylene glycol. Furan dicarboxylic acid can be prepared from natural biomass, such as starch or cellulose, by biofermentation or chemical methods.PEF fibers are similar to polyester PET fibers, with relatively close melting points and glass transition temperatures, and although there are reports of some biodegradation of PEF, however, the rate of biodegradation is slow, and is not a biodegradable fiber according to the current biodegradable composting standards.

Other bio-based fiber materials such as nylon 56 and bio-based PDT fibers also fall into this category.

Petroleum-based Biodegradable Polymers and Fibers (Quadrant II):

As mentioned earlier, the biodegradation performance of polymer materials is a more complex process, which is closely related to the chemical structure and properties of the materials themselves. Some chemical fiber materials, although mainly derived from petroleum-based sources, exhibit better biodegradability due to their more flexible molecular chain structure, easy hydrolysis of ester bonds, and microbial or biological enzyme degradation, for example:

Dimethyl oxalate (DMO), an important compound in the preparation of PGA (polyglycol), which is produced from coal as a raw material by hydrogenation, hydrolysis and polymerization. Although PGA is made from coal, its biodegradability is very good, it can be completely degraded within 1-3 months, the degradation products are water and carbon dioxide, completely non-toxic and harmless, and it is often used for absorbable surgical sutures, which have both high biodegradability and biocompatibility. PGLA (polyglycolide), on the other hand, is made by copolymerizing 9 parts of PGA (polyglycolide) and 1 part of PLA (propylene glycolide) in a certain ratio. If propylene glycol ester is prepared biologically, PGLA can be called a bio-based and biodegradable fiber.PGLA has high tensile strength, good biocompatibility and biodegradability, and is also commonly used in absorbable surgical sutures.

Others, such as PBAT and PBST, are also mainly derived from petroleum base.PBAT and PBST are prepared by copolymerization of butylene glycol adipate (PBA), butylene glycol butyrate (PBA) and butylene glycol terephthalate (PBT), respectively, and their material properties are both PBA and PBT, with good elongation at break, ductility, heat resistance and impact properties, and at the same time, have excellent biodegradable properties. Biodegradable properties. To be applied to agricultural land film and other film materials, fiber applications are still in the development stage.