On April 30, a new study was published in the British magazine Nature Communications. A bacterial spore is embedded in polyurethane (TPU) plastic. This plastic can degrade 90% within 5 months after contact with soil.

What's even more amazing is that these modified Bacillus subtilis spores can almost completely survive in the extremely high temperature environment of plastic processing (135°C), and can toughen plastics by 37% and increase tensile strength by 30%.

The technology, from a team at the University of California, San Diego's Jacobs School of Engineering and the Materials Research Science and Engineering Center (MRSEC), has the potential to help alleviate the problem of plastic pollution.

Thermoplastic polyurethane (TPU) is a tough plastic commonly used to make items such as shoes, sporting goods, phone cases and car parts, but it currently cannot be recycled and most ends up in landfill or in the natural environment.

The first problem to overcome is that the high temperatures used to produce the plastic kill most bacterial spores. In the new study, Bacillus subtilis spores were genetically engineered to withstand such high temperatures and found that 96% to 100% of the edited bacteria survived the plastic processing temperature of 135°C, compared with unedited bacteria only 20% survive.

Jon Pokorski, one of the study's senior authors, said they took a number of strains, evaluated their ability to utilize TPU as a sole carbon source, and then selected the strains that grew best.

The researchers fed bacterial spores and plastic pellets into a plastic extruder and mixed them at a temperature of 135°C. Then they made the plastic strips as usual. Bacterial spores lie dormant in plastic and can withstand harsh conditions because they have a protective shield.

Ideally, you can use plastic items normally without premature decomposition, and it's only when they are dumped in landfills or in the natural environment that they begin to biodegrade. The research team tested the biodegradability of these plastics. Even in a sterile compost environment, at 37°C and a humidity of 44% to 55%, the spores re-germinated in these plastic strips and they decomposed within 5 months. 90% plastic.

Next, the researchers plan to use this technology to expand the scope of biodegradable materials beyond just TPU.

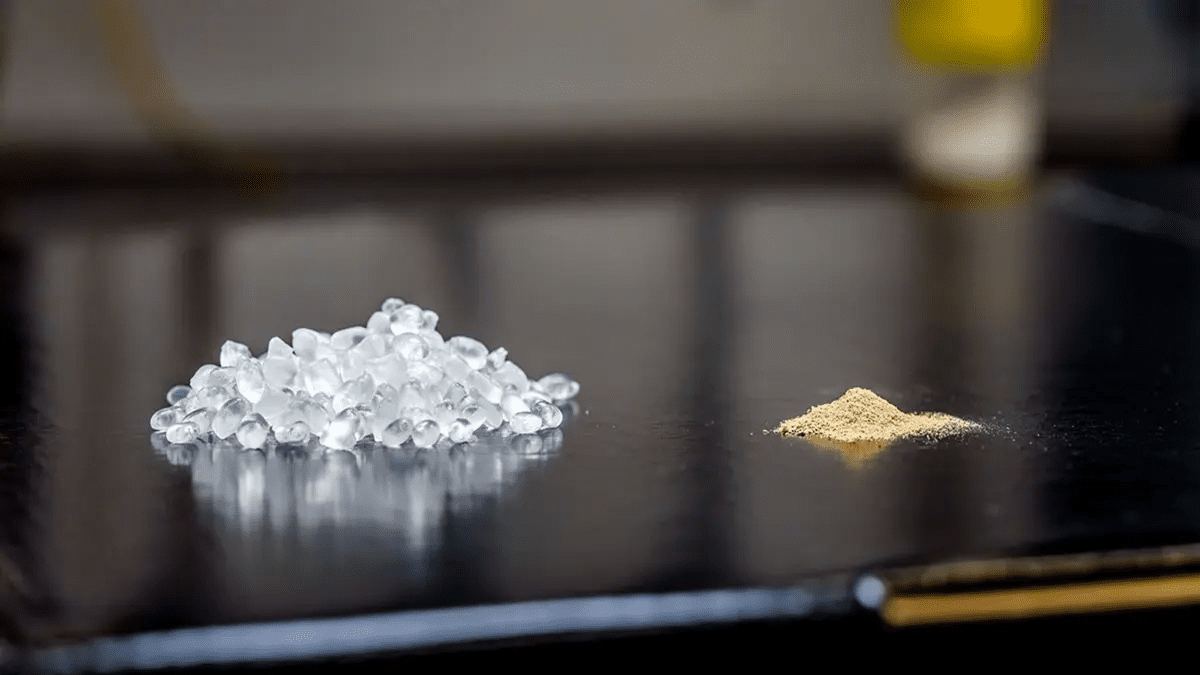

Biodegradable "living plastic" designed by combining thermoplastic polyurethane particles (left) and Bacillus subtilis spores (right).

Scientists have created a biodegradable plastic by embedding spores of plastic-eating microorganisms into the material.

Degradable biocomposite TPU. Schematic diagram of the fabrication of biocomposite TPU filled with bacterial spores capable of degrading TPUs (wild-type ATCC 6633, HST heat shock tolerant strain). Heat shock tolerance of spores is enhanced through adaptive laboratory evolution (ALE). Biocomposite TPU is prepared by hot-melt extrusion, in which dormant spores act as particulate fillers, enhancing the mechanical properties of the TPU matrix. During end-of-life testing, germinating bacterial cells promoted the breakdown of TPU.