Traditional multi-layer material composite soft bags have good high barrier properties, but are not recyclable. Single material (PP/PET/PE) structure is a fully recyclable solution, but one of the biggest technical difficulties is heat resistance and barrier properties.

The industry is currently improving the performance of the raw material resin, processing technology improvements to solve the problem of heat resistance of a single material packaging bags.

As for the barrier problem of a single material soft bag, there have been many innovative solutions emerge.

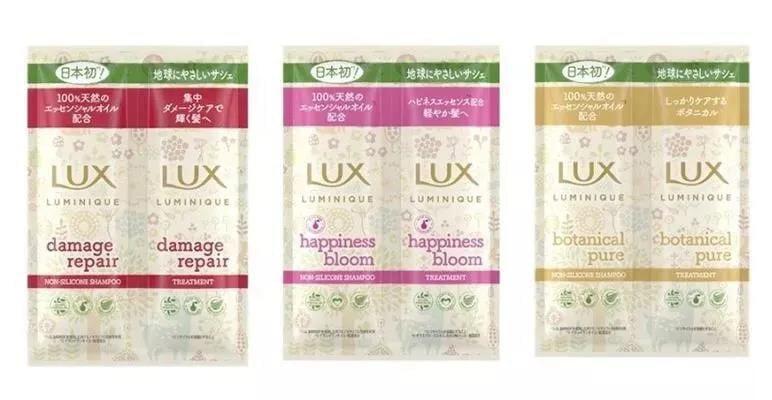

01 Unilever fragrance bag set Oxygen and water vapor barrier properties

Unilever Japan and Toppan (Toppan Printing Co., Ltd.) have jointly developed a Lux Luminique fragrance pouch set, a pouch-style packaging design using a single material, PET film, that is easier to recycle, which was launched in Japan in the first half of this year.

The material was selected by Unilever and Toppan (Toppan Printing Co., Ltd.) after continuous quality testing, and comes from Toppan Printing's GL Barrier series of films.

Traditional disposable plastic bag packaging combines a PET base material with materials such as aluminum and polyethylene. However, the most significant feature of this single-material PET flexible bag is the use of PET-grade GL film, a vapor-deposited clear barrier film from the GL barrier range, which can be combined with PET sealant.

The manufacturing method and materials ensure strong oxygen and water vapor barrier properties with low adsorption capacity, preventing loss of aroma and quality and increasing the shelf life of the product.

The Lux Luminique fragrance bag set's all-PET construction not only improves the recyclability of the soft bags, but the de-aluminumized film reduces CO2 emissions by approximately 25% during the packaging manufacturing process.

02 Mondi Replaces Aluminum Foil with Innovative High Barrier Film

Mondi, a global manufacturer of advanced packaging segments, introduces RetretTouch recyclable single-material steaming packaging for a range of food and wet pet food applications.

Typically, moist or semi-moist foods are heat-treated in steam or hot water distillation packaging containers to achieve sterilization, so these foods require steaming packaging.

These packages use more aluminum foil as a barrier layer and are difficult to recycle. mondi has developed an innovative high barrier film alternative to aluminum foil that maintains high temperatures during the distillation process and enables shorter processing times. The new single-material retort packaging is fully recyclable, providing exceptional shelf life for single-material packaging solutions and reducing potential food waste.

Mondi spent more than two years researching and testing the product to ensure it met important application requirements. As part of its commitment to sustainability, the launch of RetortTouch recyclable products is another step towards Mondi's goal.

03 Bost AlOx barrier and solvent-free adhesive solutions

Swiss packaging equipment and services provider BOBST launched its "Generation 2.0" high-barrier flexible packaging solution later this year, designed to replace multi-material packaging structures with a single material structure that meets the requirements of multiple applications in terms of processability, barrier and optical properties.

"Generation 2.0" includes new ultra-high and high-barrier all-polypropylene laminate bags, which are available with a clear AlOx (aluminum oxide) barrier and a solvent-free barrier adhesive/finisher. All-polypropylene laminate bags are also available with UV flexographic printing using digital inkjet printing.

In addition, "Generation 2.0" includes full low-density polyethylene laminate bags and MDO-PE laminate bags, which can use high-barrier solvent-free adhesives to achieve excellent barrier performance.

LDPE laminate bags are supplied by Dow with the raw material PE resin.

04 EMSUR full PE and PP construction to accommodate multiple product types

Flexible packaging group EMSUR introduces the EM Full RFlex range of packaging, based on a single material substrate of PE and PP, thus replacing the traditional multiple construction and providing excellent barrier and sealing properties to the packaging.