On November 29, Professor Deng Hongbing's team from Wuhan University's School of Resource and Environmental Sciences and Professor Zhou Xue's team from Huazhong University of Science and Technology (HUST) joined hands to make an important breakthrough in scientific research, successfully developing a new type of all-biomass fiber sponge that is reusable and biodegradable. The relevant research results have been published in the international academic journal “Science Advances”.

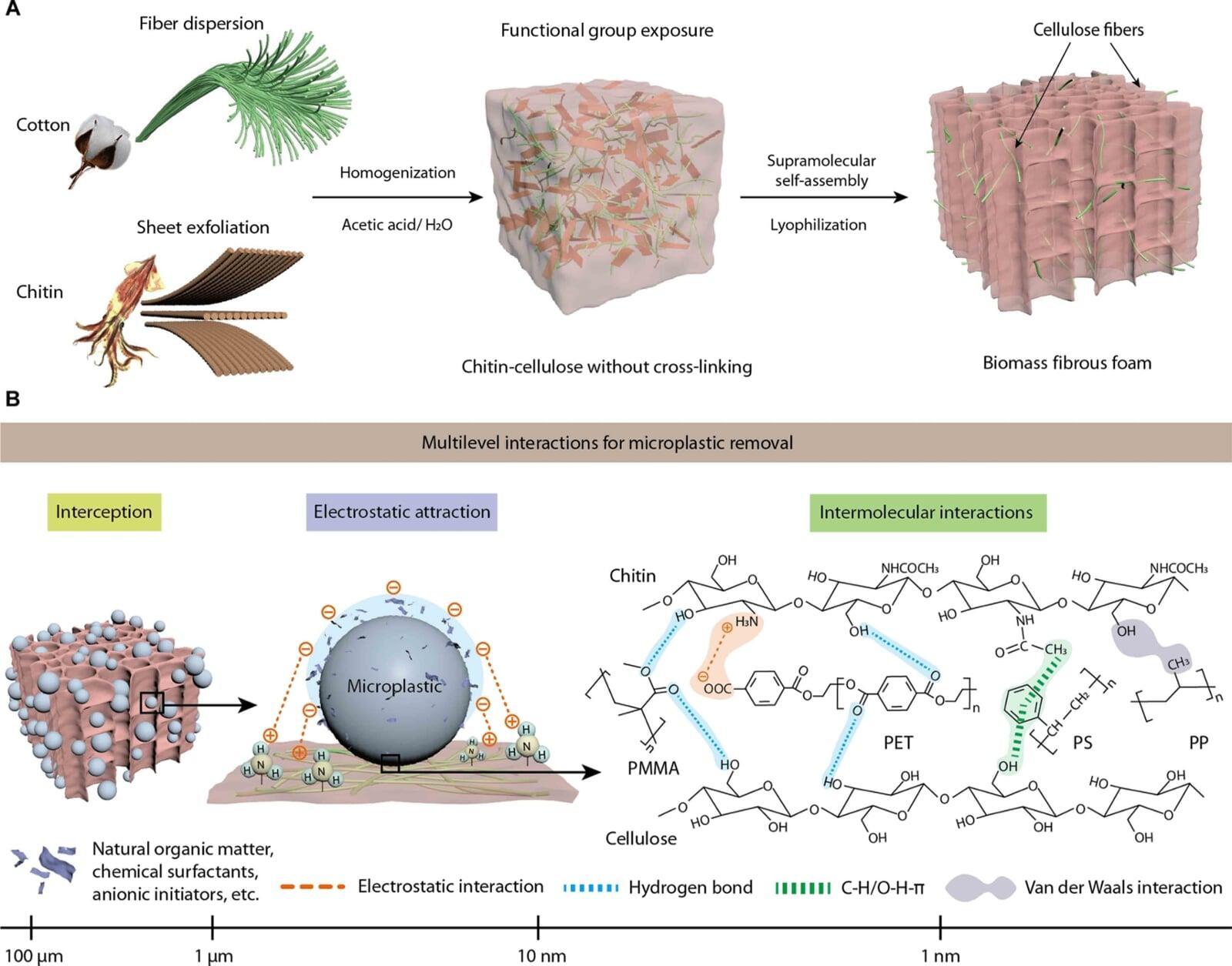

Figure 1, Sustainable self-assembled supramolecular biomass fiber foam for microplastic removal. (A) Pathway for the preparation of self-assembled supramolecular biomass foams without cross-linking of cellulose and β-chitin. (B) Due to the abundance of reactive functional groups, the biomass fiber foam removes microplastics through multilevel interactions (physical interception, electrostatic adsorption, and multiple intermolecular interactions).

Wuyang Wu, Postdoctoral Fellow, School of Resource and Environmental Sciences, Wuhan University: Our research found that the crystalline form of chitin from squid bone is different from that of lobster shell chitin, which has higher reactivity and is easier to be made into sponges that can adsorb more microplastics. China's huge squid catch, a large number of squid bone as waste can be used as raw material for chitin extraction, making more efficient all-biological microplastic adsorption sponge.

The sponge, made from chitin extracted from discarded squid bones and cotton, has a porous structure and rich surface functional groups that excel in treating microplastic contamination in water. The research team evaluated the material's performance using samples from four actual water sources: irrigation water, lake water, seawater, and pond water, and found that the material's adsorption capacity was largely unaffected by inorganic particles, heavy metals, organic pollutants, and microorganisms in the water, determining its stability in real-world waters. The study showed that this new all-biomass fiber sponge removed 99.8% of microplastics from water in the first adsorption cycle and maintained over 95% removal after five cycles, demonstrating its good reusability.

Microplastic pollution has become a global environmental challenge, posing a serious threat to aquatic ecosystems and human health. The emergence of this new all-biomass fiber sponge is undoubtedly a highlight in the field of environmentally friendly materials.

It is worth mentioning that the sponge not only has excellent adsorption performance, but also has the characteristics of reusable and biodegradable. After adsorption saturation, the sponge can be easily desorbed and regenerated through a specific treatment process, and can be recycled many times, greatly reducing treatment costs and resource consumption. When the sponge reaches the limit of its service life, it can be gradually biodegraded in the natural environment, not like the traditional adsorbent material that leaves secondary pollution hidden danger, truly realizing the environmental friendliness of the whole process from use to disposal.

Prof. Deng Hongbing said that biomass materials are an effective and economical solution to the complex problem of microplastic pollution in water, and that this all-biomass fiber sponge is simple to prepare, has the potential for large-scale production, and is expected to be applied to real-life large-scale water treatment or within household water purifiers in the near future. Prof. Zhou Xue also mentioned that inter-university teamwork played a key role in this research, as experts and researchers from different disciplinary backgrounds collaborated with each other and complemented each other's strengths to make this comprehensive and technically challenging research go forward smoothly.