Recently, researchers Akram Zamani and others from the University of Borås, Sweden, presented their findings at the spring meeting of the American Chemical Society (ACS). ACS Spring 2022 is a hybrid conference that takes place virtually and face-to-face from March 20-24.

Researchers demonstrated an artificial leather that uses organisms to transform food waste into sustainable artificial leather, as well as paper products and cotton alternatives, with properties comparable to traditional materials. They explain that this fungal leather takes less time to produce than the alternatives available on the market and, unlike some leathers, it is 100% bio-based.

Cotton is in short supply and, like petroleum-based textiles and leather, its production is linked to environmental concerns. At the same time, large amounts of food are being wasted. Dr. Akram Zamani set out to solve these seemingly unrelated problems with new bio-based sustainable materials derived from fungi. "We hope they can replace cotton or synthetic fibers and animal leathers, which can have negative environmental and ethical impacts," said Zamani, lead researcher on the project. "During the development process, we were always careful not to use toxic chemicals or anything that could harm the environment."

Just like humans, fungi need to eat. To feed these organisms, the team collected unsold bread from supermarkets, dried it and ground it into crumbs. The researchers mixed breadcrumbs with water in a pilot-scale reactor and added Rhizopus delemar spores, which can usually be found in decaying food.

When this fungus feeds on bread, it produces tiny natural fibers made of chitin and chitosan, which accumulate in its cell walls. Two days later, the scientists collected the cells and removed lipids, proteins and other byproducts that could be used for food or feed. The remaining jelly-like residue, consisting of fiber cell walls, was then spun into yarn that could be used for sutures or wound-healing textiles, and possibly for clothing.

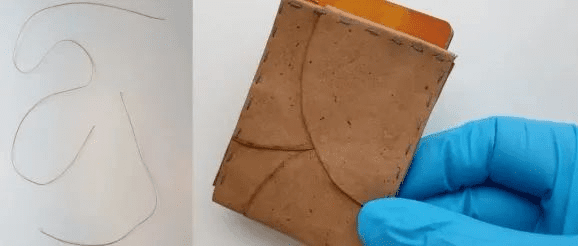

Alternatively, the suspension of fungal cells is spread flat and dried to make a paper or leather-like material. The first prototypes of fungal leather produced by the team were thin and not pliable enough, says Zamani of Brose University in Sweden. Now the team is working on thicker versions made up of multiple layers to more closely mimic real animal leather. These composites include layers treated with tree-derived tannins - which give the structure flexibility - and alkali-treated layers that give it strength. Treatments with glycerin and bio-based binders also improved flexibility, strength and gloss.

"Our recent tests have shown that the mechanical properties of fungal leather are comparable to those of genuine leather," Zamani says. while some other fungal leathers have entered the market, little information is available about their production and their properties do not match those of genuine leather, Zamani says. As far as she knows, these commercial products are made from harvested mushrooms or a thin layer of fungi that grows on food waste or sawdust through solid state fermentation. She notes that this method takes days or weeks to produce enough fungal material, while her fungi are submerged in water and take only a few days to produce the same amount of material. Some other researchers are also experimenting with underwater cultivation, but on a much smaller scale than her team.

In addition, some fungal leathers on the market contain environmentally harmful coatings or reinforcements made from synthetic polymers derived from petroleum (e.g. polyester). Zamani expects this to be in stark contrast to the Brose University team's product, which consists of only natural materials and is therefore biodegradable.

Her team is working to further refine their fungal products. They have also recently begun testing other types of food waste, including fruits and vegetables. One example is the substance left after the juice is squeezed from fruit. "It can be used to grow fungi instead of being thrown away," says Zamani. "So we won't limit the ingredients to bread because hopefully one day there won't be any bread to waste."