What are green composites?

Green composites in a narrow sense are composites in which at least one of the component materials is obtained from natural resources and is completely degradable. Also known as biocomposites or ecocomposites.

Green composites in a broad sense, from the requirements of green and sustainable development, should include composites with renewable biomass resources as raw materials and greened high-performance composites.

Why do we need to develop green composites?

The development of green composite materials is in line with the development goal of "carbon neutrality". With the continuous depletion of non-renewable resources, the development and utilization of renewable resources is particularly important for the sustainable development of the national economy and the sustainable development of the materials sector.

The research, development and application of green composite materials have gradually become a trend in the development of materials science and materials technology worldwide, and important progress has been made in material design, raw material extraction, manufacturing and processing, product use, recycling and industrialization, etc. The applications are rapidly expanding in automobiles, high-speed rail, construction, aviation and ships, etc. With the increasing shortage of petrochemical polymer materials and their composite resources, the status and role of green composite materials for sustainable development will be more prominent.

Green composite material application direction

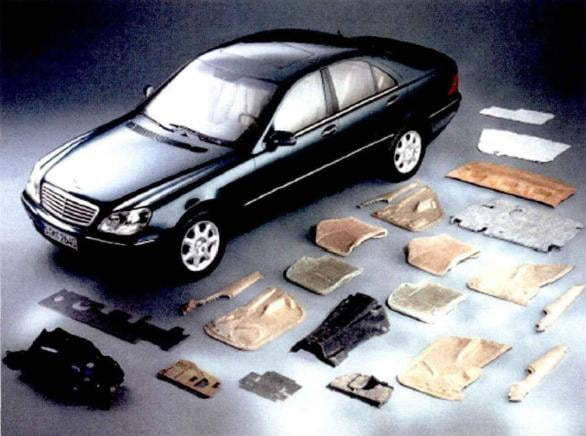

1. Automotive: Natural fibers are now used in large quantities in automotive components, they are a good substitute for glass fibers and a suitable reinforcement for synthetic polymers. They are used for trim parts, dashboard parts, doors, panels, parcel shelves, seat cushions, backrests and headrests, cabin linings, trunks, etc.

Continuous plant fiber non-woven composite automotive liner

Continuous plant fiber non-woven composite automotive interior panels

Natural fiber composite automotive parts in Mercedes-Benz vehicles

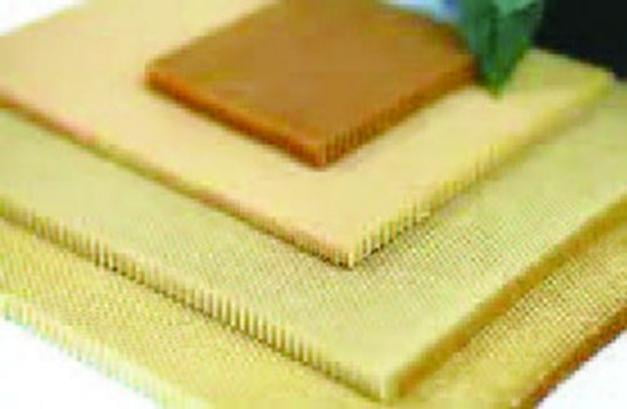

2. Aviation: In recent years, the international community is strongly concerned about the environment, resources, low-carbon and emission reduction issues, and one of the main ways to achieve these goals in the aviation transportation industry is to choose more lightweight and high-strength materials, especially composite materials, and partially replace existing materials with natural raw materials, such as partial replacement of glass fiber with plant fibers.

Plant fiber blended paper honeycomb core

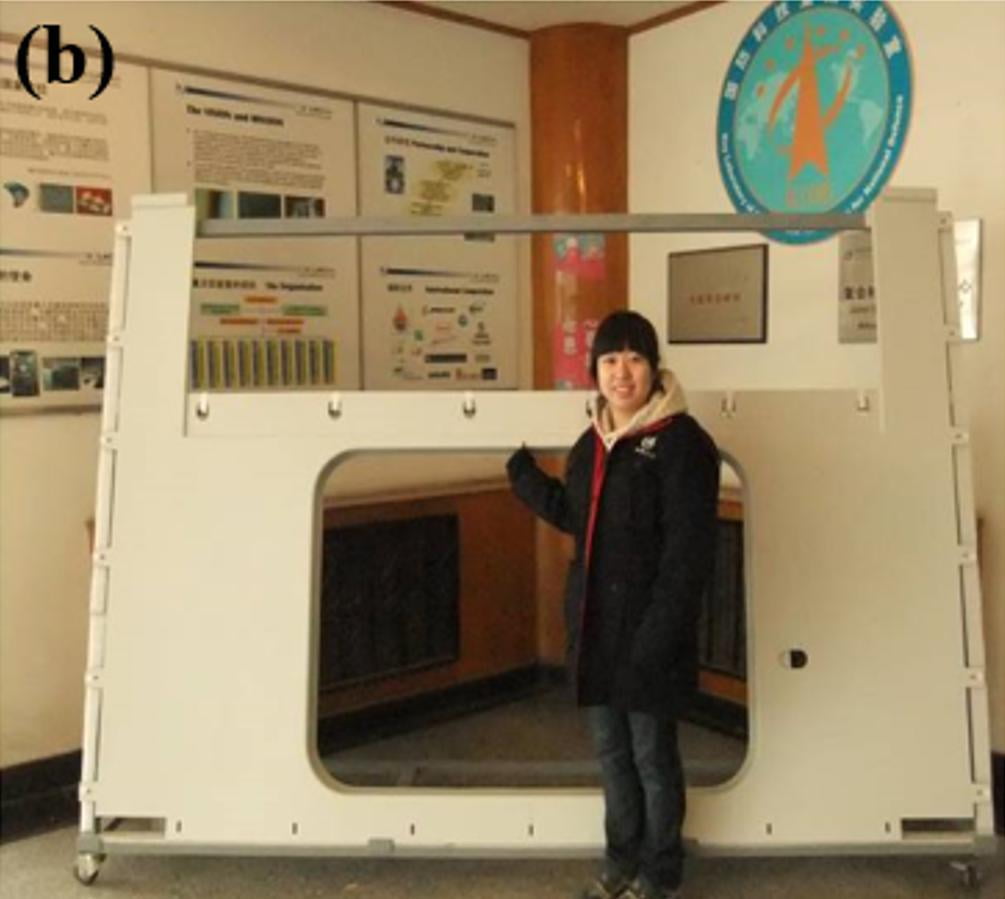

Yi Xiaosu with the director of the German Aerospace Academy and the EU ECO-CAMPASS project, and the green composite aeronautical parts in the hands of everyone

3. Rail transportation: rail transportation equipment manufacturing industry is one of the high-end equipment manufacturing industries with the highest degree of independent innovation, the strongest international innovation competitiveness and the most obvious industry-driven effect in China. In the new development period, the concepts of green, environmental protection, intelligence and sustainability make the public expectation of rail transportation safety, comfort, environmental protection and reliability increasing, in this aspect, green composite materials will have great potential.

Green Composites for Rail Transit

4. Construction: In the context of the country's strong advocacy of building an environmentally friendly society and achieving sustainable development, the development of plant fiber-reinforced resin matrix composites to help the development of green building industry has become a common concern in the field of advanced materials and technologies at home and abroad.

Green composite materials development direction

1. Expand the supply chain of raw materials. The development of new bio-resin matrix and fiber reinforcement, one is to continue to improve the performance of raw materials based on existing research, and gradually to the direction of high-end applications of composite materials; the second is to make full use of resources, the use of renewable plant resources that do not compete with food crops and cash crops, or urban, industrial waste, paper and textile by-products such as the development of bio-resin matrix materials and recycled cellulose fiber reinforced materials.

2. Develop new high-efficiency and low-cost composite processes and molding manufacturing technologies. On the basis of the existing extrusion, molding and other processes, expand to some highly digital and automated molding and manufacturing processes of high-performance composite materials, such as resin transfer molding, automatic wire laying/automatic tape laying, non-hot press tank molding of large parts, double vacuum bag molding, etc., to improve work efficiency, reduce costs and realize the molding of large-sized parts of green composite materials.

3. Expand the scope of applications. Improve the performance and quality of green composite materials, reduce costs, realize the multi-specification and multi-functionalization of products, and promote the development of green composite materials to high-end applications such as aerospace.