Nov. 12, 2024 - A new cellulose diacetate is the fastest degrading bioplastic in seawater, researchers at the Woods Hole Oceanographic Institution (WHOI) have found.

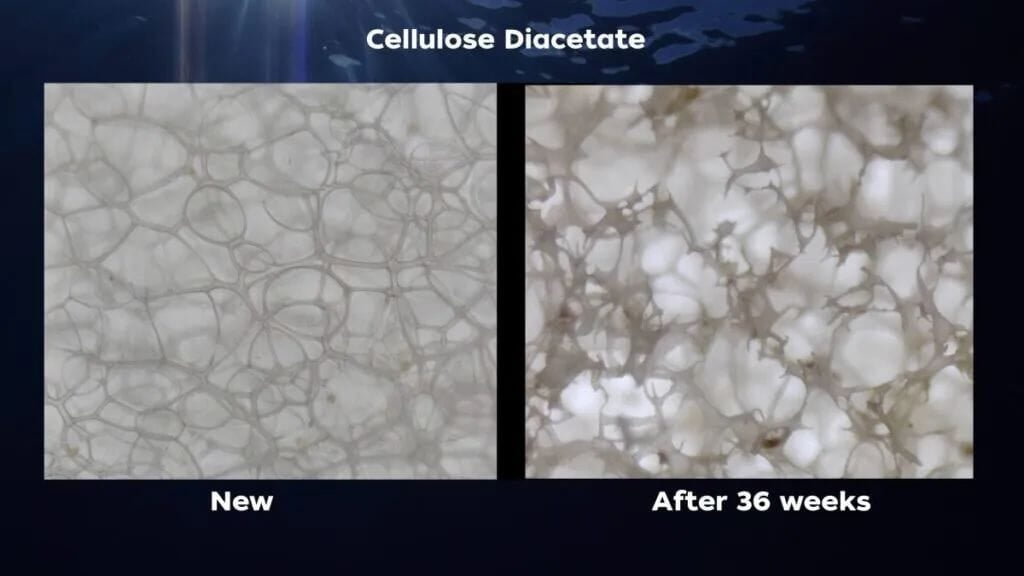

Side-by-side microscopic images of cellulose diacetate foam before and after 36 weeks of immersion in seawater. The team found that the cellulose diacetate foam lost 65-70% of its original mass.

Woods Hole Oceanographic Institution (WHOI), a comprehensive marine science research organization on the Atlantic coast of the United States, is the world's largest private, not-for-profit marine engineering education and research institution.

WHOI scientists have been working for years to study which plastics have the shortest and longest lifespan in the oceans, and which plastic products, such as straws and food wrappers, most often contribute to plastic pollution. As more biodegradable materials are developed, such as cellulose diacetate cellulose diacetate (CDA)-a plastic-like polymer derived from wood pulp-researchers are working to ensure that they can replace traditional plastics without harming the marine environment.

Now, after years of testing, the new version of CDA has been found to be the fastest degrading bioplastic material tested in seawater - and it is a promising alternative to other foam materials, such as polystyrene foam, which can stay in the environment for years. In a new paper published in 2007 ACS Sustainable Chemistry and Engineering, WHOI scientists Bryan James, Collin Ward, Chris Reddy, Yanchen Sun, and Kali Pate found that adding small holes to the CDA material - called foaming -- made it degrade 15 times faster than solid CDA and even faster than paper.

Ward, the study's senior author, said, “What excites me most about this study is its translational nature. This study is the culmination of years of research focused on understanding the fundamental controls on CDA biodegradation in the ocean.” He and the WHOI team collaborated with scientists from the bioplastics manufacturing company Eastman (Eastman), which funded the study, contributed as a co-author, and provided materials.

Ward added, “We translated the basics into the design of a new material that meets consumer needs while degrading in the ocean faster than any other plastic material we know of, even faster than paper. In a field that often focuses on the negative effects of plastic pollution rather than trying to solve the problem, this is a huge success story.”

The study consisted of monitoring cellulose diacetate foam and solid cellulose diacetate from a continuous flow seawater tank in Martha's Vineyard Island Sound in a specially designed laboratory at WHOI.After 36 weeks, the team found that the cellulose diacetate foam had lost 65-70% of its original mass.

The study was conducted in a specially designed laboratory at WHOI that monitors foam and solid CDA in tanks of continuously flowing seawater in Martha's Vineyard Sound.In this lab, researchers are able to control temperature, light, and other environmental variables to mimic the natural marine environment.

“The use of continuously flowing seawater tanks allows us to bring the dynamics of a microbially active ocean into the lab. The ocean is constantly changing and it is important that we replicate this environment by replenishing it with microbes and nutrients for more environmentally friendly experiments,” explains lead author James.

After 36 weeks, the team found that the CDA foam had lost 65-70% of its original mass.

In a previous study using dynamic seawater tanks, researchers tested straws made from standard plastic, paper, solid CDA, and foam CDA, and found that the solid CDA showed the fastest mass reduction versus the paper straws. The scientists then compared two types of straws made of CDA, one made of solid CDA and the other made of foam CDA. They found that the foam straws degraded 190% faster than the solid straws, resulting in a shorter projected environmental lifetime than the paper straws.

James says: “As a materials scientist and engineer, it's exciting that foams can be materially efficient, meaning they can be functional using as little material as possible, reducing costs and minimizing many environmental impacts. In addition, when they are made from biodegradable plastics, they can be one of the least durable materials.”

According to the study authors, replacing polystyrene foam and single-use plastics, such as takeout containers that often leak into the ocean and are not biodegradable, is one of the most pressing uses for the material. Foamed CDA products are already on the market, with Eastman introducing a compostable, lightweight tray made from foamed CDA designed to replace existing plastic trays used in industrial food packaging. Jeff Carbeck, vice president of innovation at Eastman, said, “Partnerships between industry and academia are critical to accelerating solutions to the most pressing global challenges, where academia can provide unique insights that can be utilized by industrial partners to develop solutions at scale. That's how we've partnered with WHOI; they've significantly broadened our understanding of how materials degrade in commerce and development.”

Carbeck emphasized that the study demonstrates the potential of CDA foam to help solve the challenges of single-use plastic packaging.

He said, “The properties of foams make them ideal for many packaging and insulation applications, and this study shows that foams made from biodegradable materials degrade rapidly in the marine environment if they accidentally end up there. The use of biodegradable materials in consumer products is a critical step in protecting our environment, reducing plastic pollution and fostering sustainability for future generations.”

One of the advantages of working with an industry partner is that we can ensure the scalability of the new technology,” explains Ward. One of the criteria for designing a new material is that it must be a single-use, turnkey replacement for polystyrene foam products, which means that companies converting virgin CDA to biodegradable foam don't have to invest in new equipment. The push for new plastics that are not made from fossil fuels, are compostable, and do not persist in the environment due to pollution is a win for consumers and the environment.”