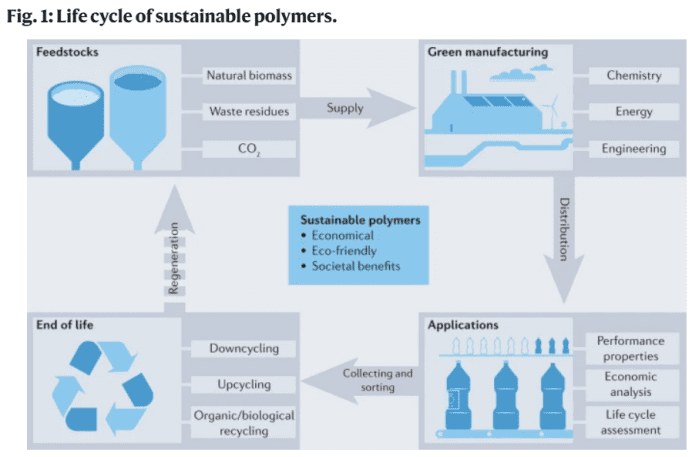

Green sustainable polymers are materials derived from renewable, recyclable or other low-carbon raw materials that are managed in an environmentally responsible manner through recycling and biodegradation at the end of life (EoL).

These include natural, modified and synthetic polymers that are sustainable throughout their cradle-to-cradle life cycle, in line with the circular economy model (Figure 1). Despite the long history of human use of green sustainable polymers, the serious environmental problems caused by the persistence and accumulation of plastic pollution on land and in the ocean have triggered new research hotspots on sustainable polymers in recent years.

Based on this, Professor Amar K. Mohanty of the University of Guelph, Canada, and others have published an article in Nat Rev Methods Primers to further elaborate the concept of green sustainable polymers from a fresh perspective. This review paper covers the entire life cycle from a wide range of available feedstocks to EoL, including principles of experimentation, characterization, application and sustainable assessment.

The authors' goal is to provide a comprehensive view for all involved in the field. Monomers and polymers made from natural products and biomass such as lignocellulose, lipids and amino acids through green chemistry are a promising field. In addition, the authors discuss data deposition and entry requirements for sustainable polymers, which are neglected in most papers, to guide the rational design of future sustainable polymers.

Synthesis of green and sustainable polymer materials

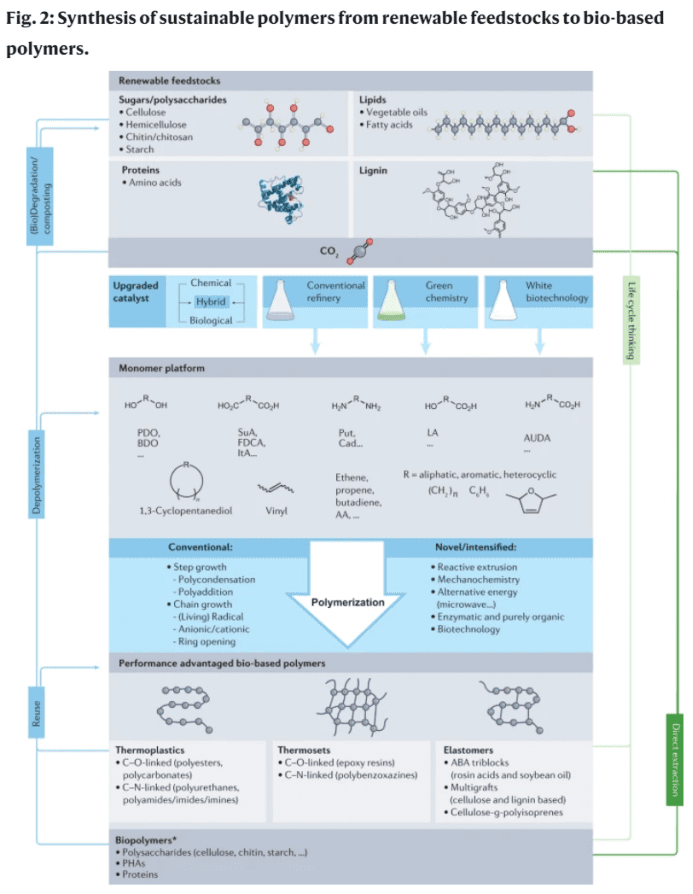

The development of most sustainable polymers begins with the extraction of compounds of interest from biomass feedstocks, which are ultimately processed into products of interest (Figure 2). Typical steps include biorefining (production of chemicals from biomass), polymerization, processing (e.g., post-polymerization modification, injection/blow molding/compression molding, 3D printing, self-assembly), and post-treatment (reuse, recycling, or biodegradation).

This can be highly dependent on the particular raw material and application. In this section, the authors discuss in detail the methods used in each step of the development of sustainable polymers.

Characterization and testing of green and sustainable polymer materials

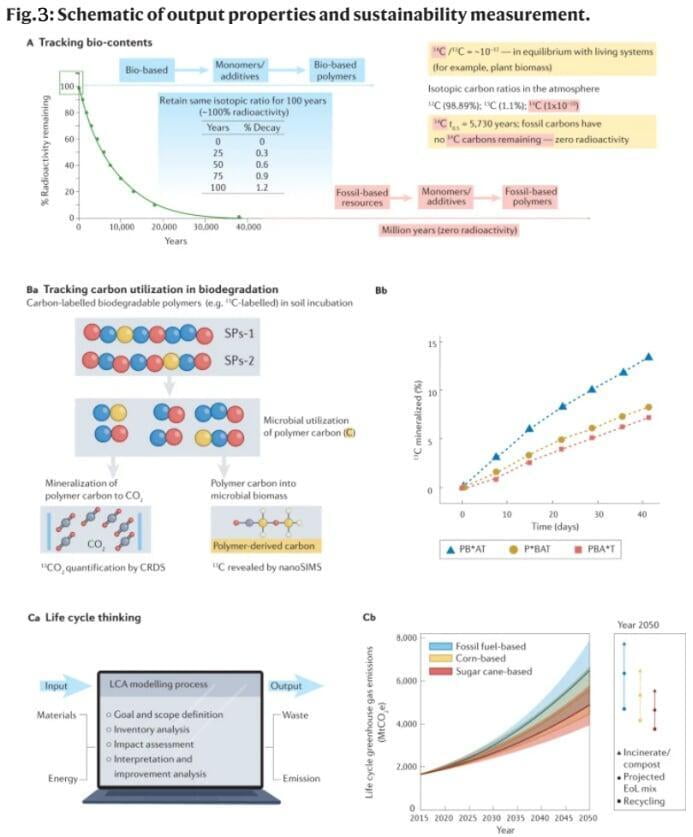

Proper characterization to ensure reproducible processing and performance is essential to bridge the gap between experimental development and practical applications of sustainable polymers. This section describes typical characterization methods and outputs for sustainable polymers from raw materials to EoL. These technologies inform users of sustainable polymer design options by providing information such as monomer yield and selectivity, as well as an assessment of sustainability through LCA (Figure 3).

Application of green and sustainable polymer materials

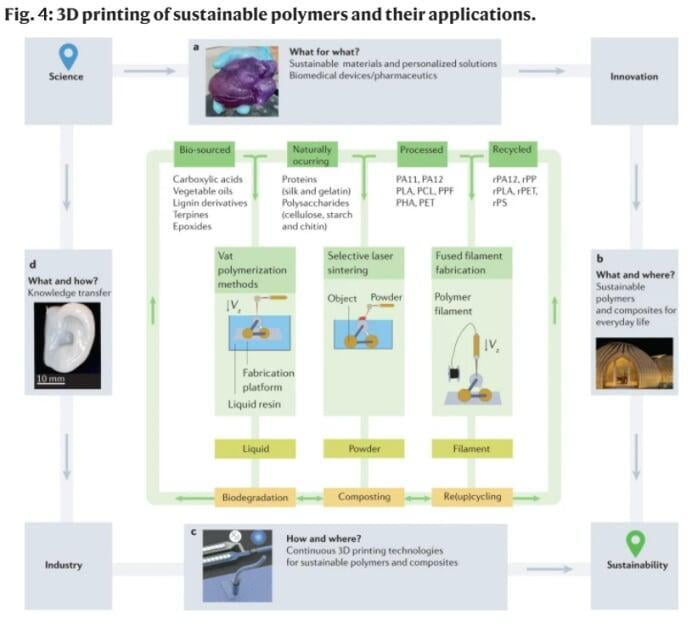

In this section, the authors present several major challenges facing the field, mainly the commercial prospects of sustainable polymers as commodities in the high-end sector. Commercial applications of sustainable polymers, highly heat-resistant sustainable polymers, sustainable polymers for 3D printing (Figure 4), and market developments for sustainable polymers are also reviewed.

Reproducibility and data deposition for the preparation of green and sustainable polymers

In the development of sustainable polymers, reproducibility begins at the beginning of the material life cycle and is accompanied by the reproducibility of raw materials. During transportation and sorting, the composition ratio of the raw material is influenced by the growing season, the collection method/location and the storage method; all of these factors affect the sugar content of the material, among others. It is important to consider this reproducibility to ensure consistent yields and selectivity of monomers extracted from biomass for large-scale production of polymers. Other reproducibility issues arise from energy efficiency and recyclability, mass/thermal/quantum conversion in the polymerization process and EoL processing conditions.

Data deposition and sharing in the field of sustainable polymers is crucial, especially for biodegradation or composting. Due to uncertain data consistency and unreported failed tests, many research projects incorrectly conclude that some certified biodegradable plastics are non-biodegradable or non-compostable in their experimental results, or that some suspect plastics are biodegradable through mass loss or virtual observation. Researchers should provide data deposition and visual display of data (e.g., time dependence of CO2 release) related to characterization conditions (e.g., compost composition, pH, temperature, and moisture) to make experimental data comparable. In addition, the creation of relevant databases has contributed to better access to big data for collective research on sustainable polymer synthesis and processing.

Challenges and Opportunities

Sustainable polymers still face the challenge of mass production and widespread commercialization. These challenges stem from two main missing factors - the lack of efficiency and a unified approach to conversion, and the lack of a clear understanding of the target product. Due to these missing components, there are not enough synthetic routes and properties needed to produce commercial petrochemical polymers for alternative products. These two issues were recognized at the beginning of sustainable polymer substitution research, but have not been effectively addressed even with the overinvestment in research. The products synthesized with one technology may be diverse, leading to different monomer and polymer structures, each requiring information on atomic economy and conversion prospects. This discrepancy creates research uncertainty, including issues related to product performance and synthetic pathways. Sustainable polymers face two major barriers to commercialization - limitations to effective reprocessing (recycling, reuse, biodegradability and compostability) at the time of product EoL, and limitations to scaling up production processes and costs.

Outlook

Over the past two to three decades, researchers have worked on the research and development of sustainable polymers by integrating renewable monomers into well-defined high-performance polymers and designing innovative solutions for their biodegradation and recycling. The rapid development of polymers cannot be achieved without an increasing understanding and tuning of polymer structure and properties, as well as wise catalyst selection and preferred EoL choices. New science developed in the rapidly growing line of generic polymer synthesis, structures of polymers, triggered depolymerization methods, computer science, biotechnology, and LCAs have together contributed to the development of the field. The complete replacement of traditional petroleum-based polymers and composites with sustainable polymers and composites remains a distant future in all applications. Some future research areas will include the development of low-cost and multifunctional polymers that are recyclable or compostable, high-performance polymers, fibers and composites for high-temperature applications, the use of primarily agricultural and food processing wastes and non-edible raw materials, and convenient green, waste-free and low-energy processes. Close cooperation between research scientists from different fields, industrial partners, policy makers and social organizations needs to be established, as well as raising public awareness of the SDGs.

In addition to renewable feedstocks such as sugars, lipids and proteins (amino acids), lignin-based aromatics and CO2-based sources are of interest to researchers, as the former can expand the use of sustainable polymers in high-temperature applications, while the latter is directly related to reducing the carbon footprint.

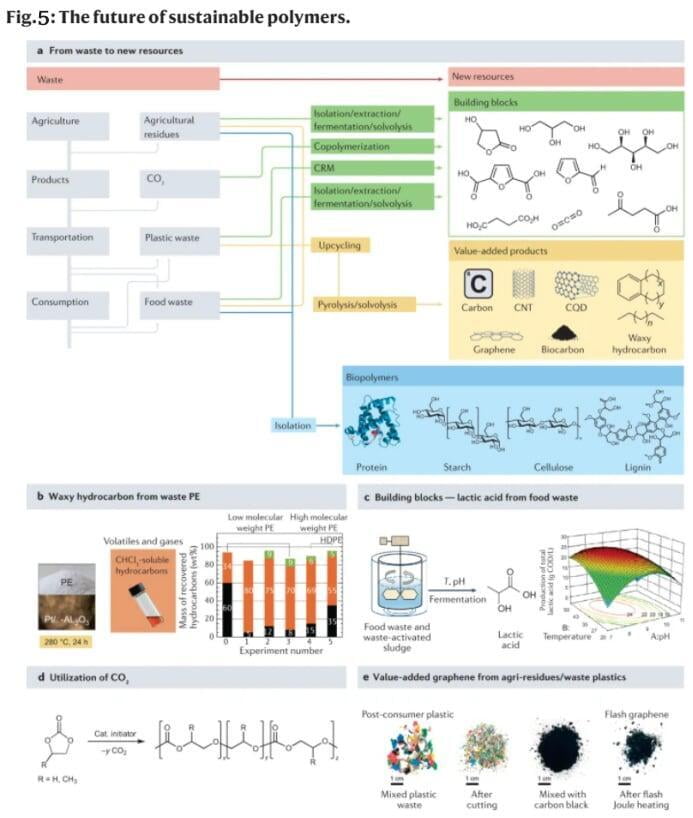

Regarding emerging commercial bio-based sustainable products, a recent European study screened the most important product value chains currently under development. This includes large-volume biomass, small-volume high-value biomass, and municipal biowaste products. The use of municipal waste as a raw material for monomers or blocks, value-added chemicals and bio-based polymers will be one of the future focuses of sustainable polymer development (Figure 5). The products identified include biocomposites, bioresin prepregs, carbon fibers and biopolymers derived from municipal waste. However, when evaluating a feedstock, it is the environmental and human impact of the feedstock that is important, not just its generation-based classification. The focus should be on the availability of resource-efficient technologies that can convert feedstocks into bioplastics, chemicals, or other materials with minimal energy, water, and other inputs, while providing the same performance as fossil fuels. These technologies must also reach commercial scale.

Summary and Outlook

Ironically, the plastic era of the 1950s (The Age of Plastics) began as an effort to conserve natural resources, but brought undeniable benefits to the world in terms of safety, energy efficiency and conservation. However, the planet is now facing massive plastic pollution, fueling concerns about climate change. We urgently need a second plastic era that leaves a smaller footprint on our planet - rightly referred to as the era of sustainable polymers. The research, development, scaling and implementation of more sustainable polymers is still in its infancy. The relative maturity of the petrochemical industry, with all of its high-volume refinery products already in use, makes it difficult for newer, more environmentally friendly materials to compete.

The problem has the potential to be addressed through legislation, including a ban and tax on single-use plastic waste, to address the proliferation of plastic waste, especially in emerging economies such as Asia and Africa. Academic and industry partners willing to pay more for sustainability are experimenting with the market's response to plastics to reduce environmental impact, and consumer preferences will play a role in adoption. Emerging sustainable materials may also have unexpected advantages over fossil plastics, such as improved energy or noise absorption, so researchers must remain vigilant in looking for these enhanced properties, as they will be preferred over fossil plastics.

There is room for improvement in all aspects of sustainable polymer development, including the use of waste feedstocks such as lignin, carbon dioxide and inedible biomass, energy/water efficient manufacturing guided by green chemistry principles, design of environmentally responsible EoL materials, and improved separation, reuse and recycling technologies for conventional plastics.