Researchers at the University of Victoria are making sustainable packaging from natural products, including celery and pea starch, to replace some plastics. When protein is extracted from plants such as peas to produce protein-rich edible foods, a large amount of waste is usually left behind in the process.

According to Professor Vincent Rouillard, a researcher at the Victoria University (VU) Institute for Sustainable Industries and Liveable Cities, up to 25% of the protein can usually be extracted from the product. But what happens to the remaining 75 percent?

"Getting rid of this organic waste is a major issue. If you just don't handle it carefully, it can cause more problems for the environment," Rouillard said. He has been working on packaging dynamics and packaging materials for over 30 years, along with VU researchers Dr. Matthew Lamb and Dr. Marlene Cran. The team worked together to design a sustainable solution.

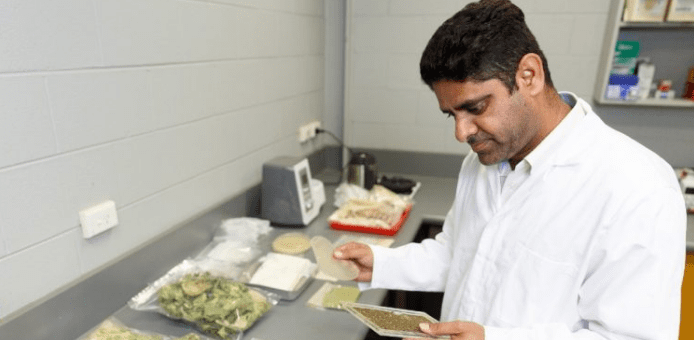

Researchers at the University of Victoria have studied the manufacture of circuit boards and flexible trays from agricultural waste and residues

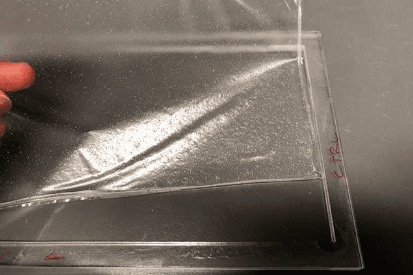

"A few years ago, we extracted the waste starch material left over from a production process that involved separating proteins from yellow peas. Through a treatment process involving heat treatment and the use of different types of additives, we managed to create clear films from them," says Rouillard.

Plastic film made from waste

VU's recent work in this area, funded by the Victorian Government, is an important step towards sustainability.

Moving to a circular economy must include the use of compostable and bio-based materials, and there will always be a place for traditional plastics, but in the case of single-use packaging, it makes more sense to use materials that come from nature," Cran said.

After extracting leftover celery, zucchini and lettuce from local Victorian farms, the researchers conducted extensive tests on each material to determine its suitability as an alternative packaging product.

The researchers conducted mechanical tests and impact tests in different environments. Often, application-sensitive tests are performed to look at solubility, as one wants to know if the material will dissolve in water and if it will swell if exposed to high humidity environments, and tests are performed to determine the material's end-of-life characteristics.

The ultimate goal is to create functional materials such as packaging, films, rigid sheet materials or cushioning materials, but finding materials that perform similar functions to traditional packaging plastics can present challenges.