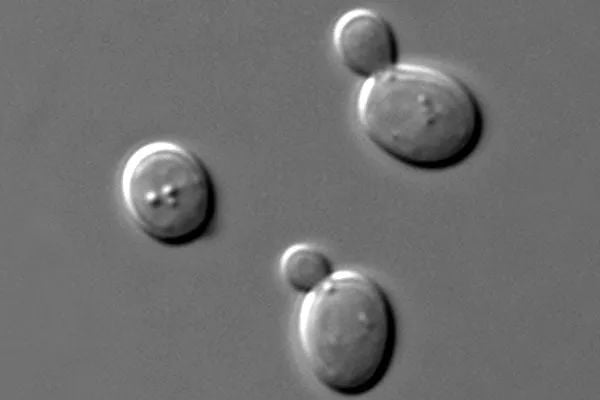

Yeasts have been used for thousands of years in the production of beer and wine and to add fluff and flavor to bread. They are nature's little factories that feed on sugars from fruits, grains and other nutrients, and from this menu produce alcohol for beverages and carbon dioxide to make bread swell. Not long ago, a U.S. university developed a bioengineered yeast that can turn waste products such as husks and stems from agricultural products into industrial fuels, pharmaceuticals and plastics.

A team of researchers at Tufts University's School of Engineering, an Ivy League school in the U.S., turned a new type of yeast into something useful by altering the protein sensors on the yeast to allow it to feed more extensively on "waste biomass". They wrote up the results in a paper that was published in July this year in the Journal of Metabolic Engineering on the ScienceDirect website, a scientific and medical bibliographic repository.

Why is it important to create yeast that can feed on these agricultural leftovers?

Crops such as cornstalks, husks and leaves, and wheat stems are often discarded because they are difficult to break down and digest, resulting in an estimated 1.3 billion tons of "waste biomass" each year, but these "waste biomasses" contain large quantities of sugars, such as xylose (pentose), arabinose (gum aldose), and cellobiose, which can provide an adequate source of sugar for industrial yeast.

Previously, scientists have modified yeast so that people can use it to produce drugs such as insulin, human growth hormone, antibodies, and even to design and produce vaccines, among other things. There are also bioengineered yeasts that can be used as feedstocks for bioplastics, including polylactic acid. This feedstock can be made into a variety of products, such as packaging materials and consumer goods, and does not require additional refining from petroleum.

Engineering yeast to grow on biomass sugar

The new yeast made by the Tufts team can feed on sugars such as xylose, arabinose, and cellobiose, which can be extracted from the indigestible woody parts of crops that are often discarded after harvesting, providing enough sugar to fuel a huge industry in yeast biosynthesis.

Nikhil Nair, associate professor of chemical and biological engineering at the Tufts School of Engineering, told the school's newsroom, "If we can get yeast to break down this 'waste biomass,' we can reduce the amount of carbon dioxide caused by combustion and make bio fuel to supply the instruments used to cultivate crops."

Nair and his team believe that the best opportunity to efficiently consume waste biomass sugars may be to modify the existing genetic "dashboard" that yeast uses to regulate the consumption of galactose, a sugar commonly found in dairy products. The dashboard, called regulators, includes genes for sensors that detect the presence of sugar and trigger enzymes that chemically break down sugar so that its carbon and oxygen components can be rebuilt into new ones. Most of the new components are small molecules and proteins that the yeast itself needs to survive, but they could also be new products that scientists might be able to modify in yeast.

In an earlier study, the researchers modified the galactose regulator so that the protein sensor detected the biomass sugar xylose and triggered the enzyme to process xylose instead of galactose. “Protein sensors" are proteins that select for certain specific or specified chemicals. For this purpose, they activated this protein sensor and converted it into a special protein sensor, Gal3pMC, which enables the yeast to break down xylose and arabinose.

The team also chose natural yeast to use a "protein sensor" (Gal3p) to break down galactose during its growth. The protein sensors for galactose, when activated, not only make the metabolic genes for galactose visible, but also remodel the overall metabolism to support efficient yeast growth.

Sullivan made only minimal changes to the regulators already designed for xylose by altering the sensor proteins to accept xylose, arabinose, and cellobiose more generally. With the exception of a few minor changes, the new regulator allows yeast organisms to grow on all three sugars at a rate comparable to yeast grown on the natural sugars glucose and galactose.

In addition, this experiment did not require expensive experimental procedures such as functional genomics and reverse genetics to remove some of the yeast's genes that are detrimental to the breakdown of xylose.

The results of this experiment show that they can use the yeast containing the Gal3pMC special protein sensor to engineer catabolism that interacts with natural metabolism to efficiently break down those "waste biomasses".

Sean Sullivan, a graduate student on the team, said, "Getting yeast to grow on xylose is an important advance, but redesigning different yeast organisms to grow on each biomass sugar is not the best approach. We want to design a single yeast organism that can feed on intact or nearly intact biomass sugars."

Another graduate student, Dr. Vikas Trivedi, said, "We modified yeast's digestion of sugars through a minimal engineering approach. Because yeast has mechanisms to grow on unnatural sugars, it only required us to adjust its protein sensors and mechanisms for recognizing sugars."

Improving the back-end of production

In fact, the reason yeast has been re-engineered many times to make compounds for drugs is because they are difficult to synthesize artificially and often need to be extracted from a number of rare plants. These include scopolamine, used to relieve motion sickness and post-operative nausea, atropine, used to treat Parkinson's disease, and artemisinin, used to treat malaria.

Ethanol produced by yeast is a widely known biofuel, but researchers have also modified the organism to allow yeast to produce other fuels such as isobutanol and isoamyl alcohol, which burn to produce more energy than ethanol.

Associate Professor Nair added, "The scientific community is constantly creating new yeasts that allow it to produce more new products. We're using new yeasts to allow them to break down these agricultural wastes so that things that were previously unavailable can be turned into fuels, medicines, plastics or other useful things."