Yeast is one of the most familiar microorganisms in our lives; bread yeast is used to steam buns and bake bread, and brewer's yeast is used to brew beer. In addition, there are many other weird and wonderful yeasts, such as the one that "eats" methanol for high protein production (e.g., Pasteur's Picot yeast) and the one that "eats" xylose for crazy growth (e.g., Hansenula polymorpha).

Will new yeasts be created in the future with even more functionality? The scientists' answer is: of course!

1. Yeast is a cell factory.

Before we look at how scientists can "create" more new yeast, let's take a look at how yeast "works".

Although both baker's yeast and brewer's yeast belong to the brewer's yeast, the specialty of baker's yeast is to "eat sugar and produce gas", and the carbon dioxide produced will make the buns or breads porous and fluffy; while the specialty of brewer's yeast is to "eat sugar and produce alcohol", and, of course, it will also produce a small amount of other aroma components, which will give the wine a variety of flavors.

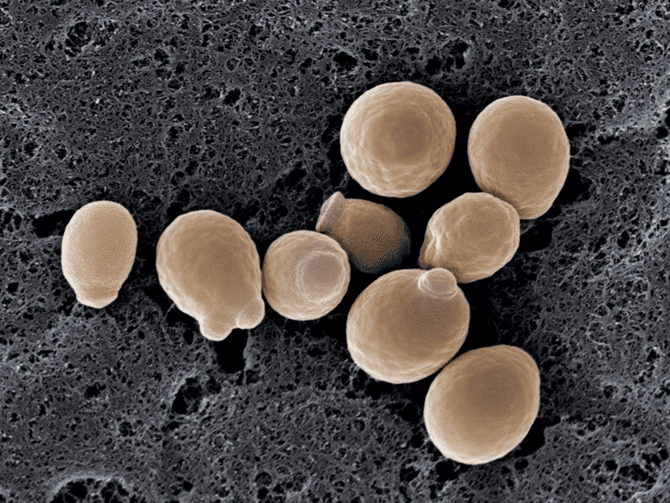

dry yeast

Let's take the example of brewer's yeast "eating glucose to produce ethanol", and think of yeast as a factory, where glucose is the raw material, and the raw material is transported to the factory (i.e., inside the yeast cells), and then processed in different "workshops", and then transformed step by step into the products - ethanol and carbon dioxide.

yeast cell

The yeast we currently have is diverse, but we also want to have yeast that is versatile and has high performance.

In order to have a wider variety of yeast, the focus is on modifying the "factory". Researchers have come up with the idea of gene editing. Altering the design drawings of the yeast factory (the genetic sequence of the yeast cells) to modify the layout of the factory, and then adjusting the number and function of the "workshops" according to the new drawings. Gene editing is equivalent to using a pair of scissors with self-navigating function, which can precisely cut a notch in the corresponding position of the yeast chromosome according to the human setting, and then repair the notch through the target DNA sequence.

Genetic engineers artificially modify genes

Many scientists do research on yeast, such as the team of Professor Jay Keasling, a member of the United States Academy of Sciences, synthesized artemisinic acid, a precursor of the anti-malaria drug artemisinin, through the modification of brewer's yeast, which has made an important contribution to the treatment of malaria on a global scale, and has also proved that yeast is "very useful".

2. Yeast: go fix some glucose and eat it!

The yeasts we mentioned in the example above only start to function after "eating" glucose, which is the favorite "food" of the yeasts.

However, glucose comes mainly from grain, and giving glucose to the yeast means that the yeast will be competing with humans for grain. What can be done to "feed" the yeast without reducing the amount of food?

That's what scientists are considering.

In recent years, countries have encouraged the vigorous development of non-food biomass resources, which include lignocellulose.

Although the term "lignocellulose" may sound unfamiliar, it is a very common and readily available substance that is a major structural component of wood and crop residues. It is a complex and multifaceted "family" consisting of three key elements.

Cellulose is a "large" polysaccharide composed of glucose, the main component of plant cell walls, is the most widely distributed in nature, one of the richest polysaccharides; Hemicellulose is a "polymer" of many different types of monosaccharides, which form a strong fibrous network between cells, achieving a tight connection between cells; Lignin is one of the components of the plant cell wall, which acts as a "scaffold" for the fibers and strengthens the entire lignocellulosic structure.

Lignocellulose is a highly valuable natural renewable resource with a wide range of potential applications as a raw material for biofermentation and biochemicals.

Yes, it can be a source of nutrients for yeast.

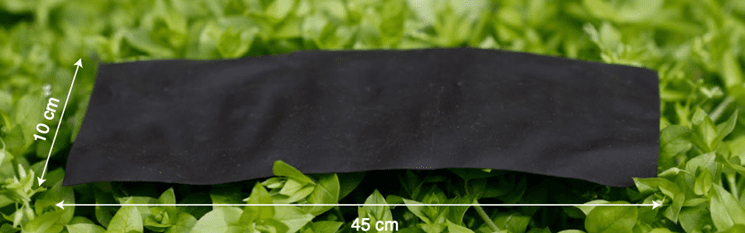

A robust, biodegradable and recyclable lignocellulosic bioplastic

However, due to their very stable structure, they are difficult to be utilized directly. Therefore, specific treatments, such as the use of strong acids or bases, are needed to break down cellulose and hemicellulose into their base monosaccharide components (e.g., glucose and xylose), and these base monosaccharides can then be utilized directly by some yeasts.

However, this does not mean that now the culture of yeast can completely abandon the grain and the use of lignocellulose, the reason mainly lies in the lignocellulose needs to be hydrolyzed into monosaccharides in order to be used by the yeast, and the preparation of hydrolysis is still relatively high cost, and hydrolysis of the liquid in addition to the main components of glucose and xylose, there are some inhibitors of the components (eg, furfural, furan, etc.), the growth of the yeast has a certain inhibitory effect.

Therefore, microbial fermentation using lignocellulosic hydrolysate is not widely used at present.

3. "Three birds with one stone" to feed the yeast

Yeast loves to "eat" glucose, when glucose and xylose are present at the same time, yeast will eat glucose first and xylose only when glucose is finished, which makes yeast use lignocellulosic hydrolysate at a slower rate.

How can yeast use lignocellulosic hydrolysate efficiently?

Recently, a team of researchers from the Chinese Academy of Sciences, Zhou Yongjin, modified the polymorphic Hansenula polymorphicus yeast through genetic engineering, which enhanced the yeast's uptake and digestion rate of xylose without affecting the digestion rate of glucose, thus realizing the simultaneous utilization of glucose and xylose, and improving the efficiency of polymorphic Hansenula polymorphicus yeast's utilization of lignocellulosic hydrolysis solution, as well as synthesized fatty acids and 3-hydroxypropanoic acid through the modification of polymorphic Hansenula polymorphicus yeast.

The term 3-hydroxypropionic acid is relatively new to us compared to fatty acids that can form fats and oils.

In fact, 3-hydroxypropionic acid can be used as a raw material for many chemicals, for example, 3-hydroxypropionic acid can be polymerized into poly-3-hydroxypropionic acid, which is used as a biodegradable plastic, and if used in large quantities, it can alleviate the "white pollution"; 3-hydroxypropionic acid can be dehydrated to form acrylic acid, which can be further prepared into acrylic resin, which is the main ingredient of the decorative paints and varnishes, and all of them are closely related to our lives.

Chinese scientists through the lignocellulosic biorefinery production of fatty acids and 3-hydroxypropionic acid, lignocellulosic as a non-food biomass, compared with the traditional glucose biorefinery, to avoid the "competition with people for food", but also to reduce the straw, waste wood directly burned caused by atmospheric pollution, so that can be said to be "one shot, three birds with one stone".

4. Conclusion

Yeast cell factories have shown great application value in scientific research, with scientists transforming yeast through precise gene editing techniques to synthesize a range of high value-added products such as biofuels, fine chemicals, spices and food additives. However, traditional glucose-based biorefineries may have the dilemma of competing with man for food, and in response to this dilemma, the modified yeast is able to efficiently utilize glucose and xylose from lignocellulosic hydrolysate, as well as responding to the call for the development of non-food biomass.

Experimental studies have demonstrated the feasibility of synthesizing fatty acids and 3-hydroxypropionic acid from glucose and xylose by modifying Hansenula polymorphicus yeast, proving the great potential of lignocellulosic biorefinery. With the unremitting efforts of the scientific and industrial communities, lignocellulose will be widely used in the production process of more products in the future, providing strong support for the sustainable development of China's biochemical industry.