PLALEAVES - Premium Natural Fibres Wholesaler, Nature Materials Manufacturer, Sustainable Fabrics Suppliers, PLA Fabric Manufacturer in China

Polyester is currently used in clothing and related fiber applications, mainly poly (ethylene terephthalate) (PET), which accounts for more than 40% of the world's textiles consumption (second only to cotton), and its use continues to increase. But the production of this polyester textiles consumes fossil fuel resources and disposal polymers are added to the landfill because they are not sustainable textiles, not biodegradable and are not easy to recycle. In contrast, PLA fiber is bio based material, derived from annually renewable crops, it is 100% compostable, and its life cycle may reduce the earth's carbon dioxide levels. Recognized by the U.S. Federal Trade Commission and the European Commission believes that PLA(Polylactic Acid) fiber is a new synthetic general category, a bio based fabrics and new sustainable fabrics.

The PLA fiber further enhances the effectiveness of this new method of producing melt-spun fibers.

PLA is considered to be the most promising sustainable bio-fiber to replace the traditional polyethylene terephthalate (PET) polyester fiber in textile products.

The natural advantages of sustainable fabrics, PLA fabrics are obvious (PLA material properties):

1. Lactic acid, the raw material of Polylactic Acid fabric, is an endogenous substance in the human body. Polylactic Acid fabric can be decomposed into lactic acid in the human body for metabolic absorption, and has shown maturity and large-scale application in the field.

2. PLA is a melt-processable bio-based thermoplastic that can be melt-spun into Polylactic Acid filaments. In the case of avoiding (strong) alkaline conditions, it can be dyed with disperse dyes or direct dyes using traditional techniques.

3. PLA raw materials are completely derived from nature, are bio-based, renewable, biodegradable, and sustainable material.

4. PLA fabric is bio based polyester, has natural skin-friendly properties, natural skin feel and breathability.

5. PLA can be blended with other raw materials, such as PLA cotton blending, PLA Tencel blending, PLA modal blending, etc.6. PLA raw material has natural weak acidity, and its antibacterial rate against Myxococcus albicans, Escherichia coli, and Staphylococcus aureus is more than 95%. Its natural antibacterial properties are different from the antibacterial treatment of fabrics with chemical raw materials. What it can effectively achieve is the balance of various flora, which is beneficial to patients with skin diseases or skin allergies.

7. PLA fabric is a high UV resistant fabric and good flame retardant fabric.

8. PLA fabric has a good warmth retention effect.

9. PLA fabrics have dual-wetting properties (in the specific applications of medical fabrics below, we will have specific applications).

10. PLA fabric has a good effect of repelling mites, reaching the highest anti-mite level: AA.

In our actual production process, the defects of PLA raw materials in the application of fabrics have also been revealed, the most important of which are:

1. Although PLA raw material has good spinnability, it has low heat resistance, high rigidity, and high brittleness after long-term storage.

2. In the printing and dyeing process of PLA fabrics, due to the heat-resistant properties of PLA fabrics and natural weak acidity, the fabrics are difficult to color or have low color fastness during the printing and dyeing process.

3. The melting point of the yarns that are commercially available today is relatively low at 170 ℃. This does cause limitations in some of the downstream processing technologies, but the main concern is for the consumer after-care of garments. Garment pressing and ironing temperatures have to be lower than the popular fibers of cotton and PET, and despite the appropriate care labeling instructions being used, it is a fact that consumers often disregard these.

As a sustainable fabrics supplier, in many years of production practice, PLALEAVES has continuously overcome the defects of PLA raw material properties and the production difficulties of spinning, weaving, printing and dyeing, and finalizing. It has completed the crystal spinning of PLA fabrics, blended yarns with different materials, and spinning of PLA fabrics. The printing and dyeing of PLA fabrics, and the development of the entire industrial process for the final garment production of PLA fabrics. The PLA textiles products that have been formed are:

PLA Yarn

PLA Clothing Fabric

PLA Non woven Fabric

PLA Melt Blown Fabric

PLA Yarn

As one of the sustainable textiles companies, currently PLALEAVES realizes industrial mass production of yarns:

100% PLA:

21s,24s,32s,40s

100% Polylactic Acid filaments:

DTY 50D, 75D, 100D, 150D

FDY 50D, 75D, 100D, 150D PLA material sustainable fabric manufacturers

PLA blended yarn:

PLA/COTTON 75%/25%,70%/%30

PLA/Tencel 75%/25%, 70%/30%

PLA/Modal 75%/25%, 70%/30%

Due to the difficulty of processing PLA fabrics in the dyeing process, PLALEAVES has also developed pure PLA color yarns. Color masterbatch is added in the process of crystal spinning, which can be directly used for yarn-dyed fabrics to reduce the color fastness that may be produced by the dyeing process, to provide more choices for the development of sustainable fibres and textiles.

PLA Fabrics

The test reports of PLA fabrics of PLALEAVES in various dimensions:

Test item 1: Physical performance

No.

Name of the test item

Unit

Technical requirements

Test results

Evaluation

1

Fiber content

%

/

PLA 100%

/

2

Formaldehyde content

mg/kg

≤75

Not detected(<20)

Pass

3

PH value

/

4.0-8.5

6.4

Pass

4

Peculiar smell

/

None

No peculiar smell

Pass

5

Decomposable carcinogenic aromatic amine dyes

mg/kg

Disable(≤20)

Not detected(<5)

Pass

6

Air permeability

mm/s

/

1484

/

7

Moisture permeability

g/(m2*24h)

/

7.54*1000

/

8

Breaking strength

N

Vertical

67

/

9

Elongation at break

%

Vertical

8.0

/

No. | Name of the test item | Unit | Technical requirements | Test results | Evaluation |

1 | Fiber content | % | / | PLA 100% | / |

2 | Formaldehyde content | mg/kg | ≤75 | Not detected(<20) | Pass |

3 | PH value | / | 4.0-8.5 | 6.4 | Pass |

4 | Peculiar smell | / | None | No peculiar smell | Pass |

5 | Decomposable carcinogenic aromatic amine dyes | mg/kg | Disable(≤20) | Not detected(<5) | Pass |

6 | Air permeability | mm/s | / | 1484 | / |

7 | Moisture permeability | g/(m2*24h) | / | 7.54*1000 | / |

8 | Breaking strength | N | Vertical | 67 | / |

9 | Elongation at break | % | Vertical | 8.0 | / |

Test item 2: Banned azo dyes

No. | Aromatic amine name | Test results |

1 | 4-aminobiphenyl | Not detected |

2 | Benzidine | Not detected |

3 | 4-chloro-o-toluidine | Not detected |

4 | 2-naphthylamine | Not detected |

5 | O-aminoazotoluene | Not detected |

6 | 5-nitro-o-toluidine/2-amino-4 nitrotoluene | Not detected |

7 | P-Chloroaniline | Not detected |

8 | 2,4-Diaminoanisole | Not detected |

9 | 4,4’-Diaminodiphenylmethane | Not detected |

10 | 3,3’-Dichlorobenzidine | Not detected |

11 | 3,3’-Dimethoxybenzidine | Not detected |

12 | 3,3’-Dimethylbenzidine | Not detected |

13 | 3,3’-Dimethyl-4,4’-Diaminodiphenylmethane | Not detected |

14 | 2-Methoxy-5-methylaniline (3-amino-p-toluene) | Not detected |

15 | 4,4'-methylene-bis-(2-chloroaniline)/4,4'-methine-bis-(2-chloroaniline) | Not detected |

16 | 4,4’-Diaminodiphenyl ether | Not detected |

17 | 4,4’-Diaminodiphenyl sulfide | Not detected |

18 | O-toluidine | Not detected |

19 | 2,4-Diaminotoluene | Not detected |

20 | 2,4,5-Trimethylaniline | Not detected |

21 | Anthranilide (o-aniline) | Not detected |

22 | 4-aminoazobenzene | Not detected |

23 | 2,4-Dimethylaniline | Not detected |

24 | 2,6-Dimethylaniline | Not detected |

Test item 3: Antibacterial performance

No.

Name of the test item

Unit

Technical requirements

Test results

Evaluation

1

Bacteriostatic rate of Escherichia coli

%

≥70

95

Pass

2

Bacteriostatic rate of Staphylococcus aureus

%

≥70

91

Pass

3

Bacteriostatic rate of Candida albicans

%

≥60

96

Pass

No. | Name of the test item | Unit | Technical requirements | Test results | Evaluation |

1 | Bacteriostatic rate of Escherichia coli | % | ≥70 | 95 | Pass |

2 | Bacteriostatic rate of Staphylococcus aureus | % | ≥70 | 91 | Pass |

3 | Bacteriostatic rate of Candida albicans | % | ≥60 | 96 | Pass |

Test item 4: Color fastness

The PLA filament properties for Black fabric, laundry detergent wet abrasion color fastness level 4

The PLA filament properties for Black fabric, laundry detergent wet abrasion color fastness level 4

Choose PLALEAVES to be your #1 Bio Fabrics PLA sustainable fabrics suppliers

PLA Clothing Fabric

Because PLA fabric is 100% biodegradable fabric; good antibacterial function, friendly to the skin; close to the skin, keeping the skin dry; good air permeability, soft and comfortable when used on the skin; good mechanical properties, good anti-ultraviolet and anti-UV Static electricity, flame retardant function; anti-tear, anti-shrinkage (in the process of printing and dyeing, there are about 20% shrinkage in the warp and weft directions), non-toxic, easy to clean, not only a functional fabric, but also a renewable fabrics with fashionable alternative Taste. It is widely used in sportswear, underwear, home textiles, infant clothing, socks, shoe linings and disposable products such as diapers and wet wipes. It’s sustainable fashion and textiles.

The main current applications-Bio Fabric Clothes:

Thermal underwear:

PLA thermal underwear mainly utilizes the soft warm fabric properties of PLA fabrics. For thermal underwear of the same thickness, PLA fabrics will bring better thermal insulation effects than other natural fabrics. At the same time, the antibacterial and anti-mite effect of PLA fabric can effectively achieve the balance of various flora on the skin surface, which is beneficial to skin patients or skin allergies. During the actual wearing process in winter, we kept wearing for 30 days without odor (due to individual differences, PLALEAVES only did a 30-day wearing test). PLA thermal fabric for clothing can best fabric for cold weather.

Underwear:

PLA underwear is produced using polylactic acid fiber, which is natural clothing material, can effectively inhibit bacteria and prevent bacterial infection in private parts. Polylactic acid fiber makes the fabric feel good, has good drape, has natural antibacterial, anti-mite, anti-ultraviolet and other effects, has low flammability and excellent processing performance, and is environmentally friendly for the production of green and healthy underwear and other personal clothing products biomaterials.

PLALEAVE uses PLA as raw material (ie, polylactic acid fiber) to produce polylactic acid underwear, which is naturally green, environmentally friendly, antibacterial, anti-mite, and anti-ultraviolet, best breathable

fabric for underwear. Wearing polylactic acid underwear for a long time will significantly reduce gynecological diseases and male diseases. Polylactic acid underwear and other products can effectively inhibit the bacteria in the private parts, reduce the adhesion of bacteria in the underwear, reduce the chance of inflammation and infection, and protect the health of our private parts.

Baby clothes:

PLA fiber fabrics are ‘mutated’ from plants such as corn and cassava, are sustainable materials textiles. The plants extract starch through multiple processes, which are fermented into lactic acid by microorganisms, and then polymerized into polylactic acid. The monomers of traditional plastics are either toxic substances or carcinogens, while the monomeric lactic acid of PLA is a widely used food additive, which finally turns into glucose after glycolysis in the body. PLALEAVES fabrics will not add or produce any toxic and hazardous substances during the production and use process, and are unanimously recognized by the industry as the most promising new "ecological fabrics" in the new century, and have passed the relevant project tests of infant clothing fabrics.

Sportswear:

PLA sports wears are natural fabric clothes, the moisture management properties of good wicking, faster moisture spreading and drying mean that garments are comfortable. This is an important consideration for next-to-skin garments and particularly in the bio based textiles sportswear market.

PLALEAVES PLA fabric production MOQ:

The minimum order quantity of PLALEAVES knitted fabric:

Knitted cloth 500-600kg

Dyeing single color quantity 300kg

Woven fabric 7000 meters

Dyeing single color quantity 1000m

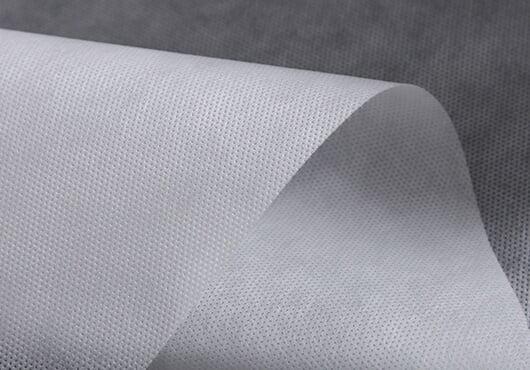

PLA Non Woven Fabric

Conventional non-woven fabrics use spun bond process or needle punching process, these two processes can only make non-woven fabrics with relatively high gram weight, while PLALEAVES 100% PLA non-woven fabrics use hot rolling (short fiber cross Laying) technology can ensure that PLA non-woven fabrics with low weight (such as 30gsm non-woven fabrics) are light and have uniform surface weight, soft and breathable, non-toxic and non-irritating, nature fabric, widely used in medical and sanitary fields: such as surgical gowns, protective clothing, disinfection wraps, masks, diapers, civilian wipes, wipes, wet face towels, magic towels, soft towel rolls, beauty products, sanitary napkins, sanitary pads, And disposable sanitary cloth, etc.

PLA is fully biodegradable and biocompatible, which makes this fiber attractive for medical applications such as wound dressings.

The unique properties of PLA raw materials can amplify the application effects of PLA non-woven fabrics in individual fields, such as surgical blankets, surgical pads, or mats for medical transfer vehicles. PLA non-woven fabrics have antibacterial, moisture-transmitting and biodegradable properties. Sex can effectively reduce the risk of re-infection in patients and effectively prevent the spread of bacteria.

At the same time, PLALEAVES also has higher weight non-woven fabrics of 30gsm, 40gsm, 50gsm, 60gsm, 70gsm, 80gsm, 90gsm, 100gsm, 110gsm, 120gsm, etc. They are effectively used in:

PLA non-woven fabrics for home decoration: wall coverings, tablecloths, bed sheets, bedspreads, etc.

PLA non-woven fabrics for clothing: lining, fusible interlining, wadding, shaped cotton, various synthetic leather base fabrics, etc.

PLA non-woven fabrics for industrial use: base materials, reinforcement materials, polishing materials, Polylactic Acid filter, insulating materials, cement packaging bags, geotextiles, and covering fabrics for roofing waterproof membranes and asphalt shingles.

Agricultural PLA non-woven fabrics: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.

Medical non woven fabric: nurse fabric, non woven medical fabric, medical use breathable fabric.

Other PLA non-woven fabrics: space cotton, thermal insulation materials, linoleum, cigarette filters, tea bags, shoe materials, etc.

PLA Melt Blown Fabric

At present, the main raw material of meltblown cloth is polypropylene (PP for short). The fiber diameter can reach 1-5 um. It is a polymer produced by the addition polymerization of propylene. It is a translucent waxy solid. The main material of mask is the raw material of melt blown cloth. At present, polypropylene meltblown non-woven fabrics are mainly made of petroleum-based and are not biodegradable. What makes everyone more worried is that under the influence of the new coronavirus epidemic, epidemic prevention materials have become necessities of people’s lives, especially disposable masks and gloves.

As the waste plastic industry is an important source of environmental pollution, it is imperative to upgrade and transform the waste plastic industry as another major source of plastic pollution.

PLA meltblown (Polylactic acid meltblown) is taken from nature, used in life, and returned to nature. It uses corn and other starch-containing biomass or straw cellulose as raw materials to ferment to produce high-gloss pure lactic acid, and prepare lactic acid into cyclic dimer lactide. , Then the ring-opening polymerization of lactide is used to produce polylactic acid. Instead of using petroleum as a raw material, as long as the plant's photosynthesis is used to form a biomass renewable resource, it is inexhaustible and inexhaustible. The waste of polylactic acid products can be decomposed into carbon dioxide and water through commercial composting or microbial degradation. The carbon dioxide and water are photosynthesized by plants to form biomass and continue to become raw materials for polylactic acid fermentation. It is a world-recognized environmentally friendly material. Polylactic acid can be used to produce meltblown non-woven fabric, which has the unique advantages of natural environmental protection, degradability, non-toxicity, anti-mite, antibacterial, breathable fabric and so on.

The advent of the new coronavirus epidemic has made masks a hot commodity in the industry, and melt blown cloth is the core raw material of masks, especially during the new crown epidemic, melt PP blown cloth has grown from obscured mask raw materials to hot “cloth gold”. Helped the healthy development of polylactic acid melt blown cloth. PLALEAVES takes the bio-based material PLA as the core raw material, researches and develops and produces PLA melt blown cloth, use the most breathable fabric for mask, creates a series of products such as polylactic acid masks, creates a healthy new life for people, and creates a new round of green economy.

At present, PLALEAVES mainly forms 30gsm PLA melt blown fabric for masks. The measured results are shown in the table:

Flow rate: | 95.0L | Flow rate: | 85.0L | Flow rate: | 32.0L |

Resistance: | 126.4Pa | Resistance: | 110.3Pa | Resistance: | 43.7Pa |

Project: | DEHS | Project: | DEHS | Project: | DEHS |

Material: | 30gsm PLA Melt blown filter | Material: | 30gsm PLA Melt blown filter | Material: | 30gsm PLA Melt blown filter |

0.3um(PFE) | 96.1819% | 0.3um(PFE) | 95.9108% | 0.3um(PFE) | 98.9965% |

0.5um | 97.0621% | 0.5um | 97.3983% | 0.5um | 99.4266% |

1.0um | 99.6299% | 1.0um | 99.5769% | 1.0um | 69.9609% |

2.5um(BFE) | 100.0000% | 2.5um(BFE) | 100.0000% | 2.5um(BFE) | 100.0000% |

5.0um | 100.0000% | 5.0um | 100.0000% | 5.0um | 100.0000% |

10.0um | 100.0000% | 10.0um | 100.0000% | 10.0um | 100.0000% |

Marks:

The PLA melt blown cloth has not undergone a crystallization process. Due to the low temperature resistance of PLA raw materials, it is necessary to add heat insulation film or use a freezer container for shipping packaging, especially in the process of ocean transportation.

Application:

Masks, filters, filter elementsPLA Protective Clothing Fabric

The PLA protective clothing fabric produced by PLALEAVES is a fully biodegradable PLA fabric made of a layer of PLA non-woven fabric and a layer of PLA film developed at the request of Japanese customers. Since PLA fabrics can be treated by incineration, the products of incineration are CO2 and water. Centralized recycling and incineration can effectively prevent the second spread of the virus.

FAQ

FAQ

Q: What is PLA fabric?

A: PLALEAVES is one of the best wholesale sustainable fabrics suppliers and manufacturers that offers eco friendly fabric made from PLA material.

Being made from natural fibers, PLA fabric is the best sustainable fabric available today in the textile industry. PLA fabric is used to replace the traditional polyethylene terephthalate (PET) polyester fiber used in textile products.

PLA fabric is made of Polylactic acid (PLA), which is a 100% bio based material derived from renewable crops and is fully biodegradable and compostable. Polylactic Acid fabric has a number of advantages compared to PET polyester fiber, such as being made from natural resources, having natural skin-friendly properties, natural skin feel and breathability and so on. PLA fabric is considered as an antibacterial fabric and it has only few disadvantages that come from being low heat resistant and highly rigid. However, as a powerful sustainable fabrics suppliers, PLALEAVES always improves the quality of its products made of PLA plastic and the growing volume of our sales proves that our clients are always satisfied with our natural fabric clothes and other PLA fabric products.

PLA fiber is currently recognized by the US Federal Trade Commission and the EU Commission and it is believed that the use of PLA fiber is a new approach in textile production, as it is a bio based fabrics and new sustainable fabrics.

Q: What is the difference between PLA and PET?

A: Let’s discuss PET and PLA separately to understand their differences:

PET

PET (poly ethylene terephthalate) is a material that is widely used by textile manufacturers to produce clothing and related fiber applications. However, use of PET has significant negative impact on the environment. One of the problems is that in order to produce these polyester textiles, significant fossil resources are required. Another disadvantage of PET is that it is not biodegradable and is not easy to recycle. The consequence is that after the usage, disposal polymers are added to the landfill and are not being able to fully deteriorate. This causes huge environmental pollution problems for the earth.

PLA

PLA fiber is a 100% bio based material. It is made from annually renewable crops and is fully biodegradable and compostable. One more advantage of PLA fiber is that its lifecycle has a potential to reduce the carbon dioxide levels of the earth.

PLA is recognized by the US Federal Trade Commission and the EU Commission and is considered as new sustainable fabrics that has a promising potential to save the environment from white pollution. This can be achieved by replacing PET polyester fiber in textile products with PLA fabrics.

Q: What are the advantages of PLA fabrics?

A: PLA fabrics products offered by one of the best sustainable fabrics suppliers – PLALEAVES, have a number of advantages, such as:

Providing high level of safety and comfort for human body

One of the main PLA material properties is that its raw material (Lactic acid) is an endogenous substance in the human body. PLA fabric is able to be decomposed into lactic acid in the human body for metabolic absorption. So, it is sustainable fabrics, which is highly secure for human body.

PLALEAVES is a manufacturer and a wholesale sustainable fabrics supplier, offering PLA fabric, which is a bio based breathable polyester fabric and it has natural skin-friendly properties. Due to this features, our natural fabric clothes provide their users natural skin feel and breathability. Besides, the antibacterial rate against Myxococcus albicans, Escherichia coli, and Staphylococcus aureus of PLALEAVES PLA natural fibres is more than 95%. As we do not use any chemical raw materials in the production of our eco friendly fabric, our PLA textile is beneficial for people with skin allergies or skin diseases.

Being eco friendly materials for clothing.

PLA fabrics are made of natural clothing materials: PLA that is used to produce these products is a 100% bio based, renewable, biodegradable and compostable material.

Wide range of application

PLA fabric has wide range of application. It can be blended with other raw materials such as PLA cotton, PLA Tencel, PLA modal, etc. and allow to produce different types of compostable clothing. Besides, our products that are made of biodegradable fibers, have a good warmth retention effect and thus they can act as the best fabric for cold weather and be used for example as warm fabric for blankets.

The breathable feature of our natural fibers allows us to offer our customers also breathable fabrics for hot weather.

High quality

As one of the most advantageous factory and wholesale sustainable fabrics suppliers, PLALEAVES provides bulk offerings of PLA eco friendly fabric. Our natural antibacterial fabric is made of UV blocking materials and fireproof fabric materials.

Quality control and quality assurance is one of the main priorities of our factory, and currently we hold certificates issued by the most reliable standard setting authorities that guarantee the high quality levels of our products.

Q: Is PLA really biodegradable?

A: PLA is a 100% bio based material, it is fully biodegradable in the nature and compostable either in the home compost or in commercial composting sides.

Q: What is PLA meltblown?

A: PLA meltblown (Polylactic acid meltblown) is a meltblown fabric made from 100% PLA. PLA meltblown especially is important during the COVID – 19 pandemic, because it is the main material used to produce masks and other medical clothing.

With the strong development and strictly products testing, PLALEAVES PLA meltblown become the main choice both for the healthy life for people and the protection of the environment.

Q: What are the difference between the PLA meltblown and PP meltblown?

A: PLA is taken from natural renewable resources; it is fully biodegradable and compostable. PP meltblown is a fossil-based material and it is not biodegradable and not compostable. The main advantage of PLA meltblown compare to PP meltblown is PLA meltblown can be easily burned after being abandoned, or by commercial composting, enables bacteria or viruses to be handled in a controlled environment, no harmful substances will be produced, no harmful substances are left in the environment for long time.

Q: How is packing?

A: Our regular packing will be same as normal fabric, by roll or by card-bord, outside plastic bag for each Individually packing, if you need bale or carton packing, just let us know with all the shipping mark details.

But for PLA meltblown fabric, due the low thermal performance, we will use insulation film inside the cargo for LCL cargo and inside the container for FCL cargo.

Q: Where is your main market?

A: PLALEAVES is one of the most eco friendly fabric suppliers based in China. Our main market is Europe and America, and we always look for new partnerships and cooperation to expand our market. Currently our sustainable fabrics are sold in more than 10 countries around the world and we have ambitions to become a leading sustainable fabrics supplier in the industry.

Q: Do you sale stock products?

A: Sorry,we do not have stock products for bulk PLA fabric items, we make by order now for PLA fabric, but if you need samples of our products, we can arrange for you.

Q: What the MOQ for bulk order?

A: The MOQ of PLALEAVES knitted fabric is as follows:

Knitted clothing fabrics: 500 – 600kg

Dyeing single color quantity: 300kg

Woven fabrics: 7000m

Dyeing single color quantity: 1000m

Q: Can you produce according to customers' design?

A: Yes, you can send us your desirable design and we will make produce the necessary product according to your design.

Q: Is it available to do customization?

A: We have a customization team, which is always ready to implement any kind of possible customization work for your order. You can send us an inquiry and provide details of your order and we will get in touch with you to discuss your order.

Q: Could you make the color as my requirement?

A: The dyeing process of PLA fabrics has some difficulties, due to the specific features of PLA. Currently, we have developed pure color PLA yarns. You may send us the required color and we will inform you about the possibility of implementing your requirement.

Q: Can we use our own label?

A: The printing and dyeing processes of PLA fabrics have some difficulties. You can send us your requirement, and we will inform you if it is possible to implement your requirement.

Q: What is your production procedure?

A: PLALEAVES is one of the most dynamic developing and innovative manufacturers and sustainable fabrics suppliers that has advanced machinery and efficient production management in place. Due to our automated production, we can ensure steady production capacity for all our products including PLALEAVES biodegradable fabric.

Q: What information should I let you know if I want to get a quotation?

A: If you are interested in PLALEAVES PLA fabrics made of natural fibres, you need to send us the details of your bulk offer, your contact details and your address. Our specialists will get in touch with you to discuss additional details if necessary.

Q: What is your production capacity? When will you start produce my order?

A: Our advanced machinery and efficient management allow us to have steady production capacity. Usually we start the production as soon as we have the complete details of the order and sample approval. The usual production lead time in PLALEAVES is around 30 days for first order plan.

Q: Do you have any safety standards for the products?

A: PLALEAVES is a sustainable fabrics supplier, for which keeping the safety standards for its production is a top priority. All our products, including Polylactic Acid fabric are strictly tested from raw material, yarn, grey fabric, and finishing fabric. It will comply with the best international standards applicable in this industry.

Q: Where is your factory located? How can I visit it?

A: We are a China based factory in Zhejiang Province and wholesale sustainable fabrics supplier. If you want to visit our factory, you need to contact with us and we will try to organize a visit to our factory for you.

Q: Will color difference exist between sample and production?

A: No, there will be no differences between samples and real products of our PLA breathable fabric. If you approve the selected samples, we will produce the same color for you.

Q: Can we use our own shipping agent?

A: If you want to use your own shipping agent for the delivery of PLALEAVES – the most eco friendly fabric, you can inform us about that and we will arrange the shipping procedure according to your shipping requirement, price may some difference with different shipping conditions.

Q: How many styles are available for my selection?

A: Currently we have color PLA yarns, natural clothing materials, PLA non-woven fabric, PLA melt blown fabric, as well as we offer wide range of wholesale PLA textile products such as thermal underwear, underwear, baby clothes, sportswear. We are also a medical fabric manufacturer and offer medical masks, melt blown filter as well as PLA protective clothing.

Q: How many tons you can supply per month?

A: For different items, we can supply up to 100mt per month and keep going as raw material capacity industrial developing.

Q: What colors can you make?

A: As there are some restrictions in the dyeing process of PLA fabrics, PLALEAVES as a manufacturer and sustainable fabrics supplier has developed pure PLA color yarns. For more details on available colors, you can send us an inquiry, we will supply you different colors with a moq.

Q: What kind of fabric do you produce?

A: As an eco friendly fabric manufacturer and wholesaler, PLALEAVES produces Polylactic Acid fabric. The raw material of these eco friendly fabrics is PLA that is a 100% biobased material and is fully biodegradable and compostable.

Currently we produce 100% PLA yarns (including colored PLA yarns), 100% Polylactic acid filaments, as well PLA blended yarns such as PLA cotton blending, PLA Tencel blending and PLA Modal blending.

We have PLA knitted fabrics, as well as PLA non woven fabric, which can be used for clothing, home decoration, for industrial use, as well as we have medical non woven fabric.

Q: Can I get a sample from your company? Should I pay for the express fee?

A: Yes, we can send you samples, all you need is to send us an inquiry. You should bear the sample cost and courier cost for the first contact. In case of further partnership, this courier cost will be carried by us.

Q: What are the applications of PLA nonwovens?

A: PLA non-woven fabrics is antibacterial fabric and has moisture-transmitting and biodegradable properties. PLALEAVES PLA nonwovens have diverse applications, depending on their types. We have low weight PLA non-woven fabrics (such as 30gsm non-woven fabrics) that are widely used in medical and sanitary fields. These PLA non-woven fabrics are used to produce surgical gowns, protective clothing, disinfection wraps, masks, wipes, soft towel rolls, sanitary napkins, etc. Meanwhile, PLALEAVES offers also higher weight non-woven fabrics (30gsm, 40gsm, 50gsm, 60gsm, 70gsm, 80gsm, 90gsm, 100gsm, 110gsm and so on) that are being used in the following fields: home decoration, clothing, agriculture, etc. PLA non-woven fabrics are used also for cigarette filters, tea bags, shoe materials, etc.

Q: Where can I buy PLA fabric?

A: If you want to purchase our PLA compostable fabric, you can place an order directly on our website (www.plaleaves.com) or through our distributors.

Q: How to get a quotation?

A: All you need is to send us an inquiry and provide the details of your order specification. Our customer support team will get in touch with you with all available options for your sustainable fabrics wholesale order.

Q: Are you a factory or trading company?

A: PLALEAVES is a China based manufacturer and wholesale sustainable fabrics supplier. We produce biodegradable yarns, eco friendly fibers for clothing as well as natural fabric clothes. All these products are made from Polylactic acid that is a 100% plant based material and is fully biodegradable and compostable.

Q: How long is your production lead time?

A: Basically, our production lead time for PLALEAVES eco friendly fabric is approximately 30days. The exact production lead time will depend on the details of your wholesale natural fibres products order, as well as the schedule of our production.

You can send us the details of your order and our customer support team will get in touch with you and provide you the necessary information.

Q: What is your major products?

A: We are a factory and wholesale sustainable fabrics supplier. We are a manufacturer of both modified raw materials, as well as ready products. Currently we have the following types of compostable fabric and compostable clothing: color PLA yarns, PLA knitted and woven fabric and clothing such as thermal underwear, underwear, baby clothes and sportswear; PLA non-woven fabric that can be used in medical and sanitary purposes, PLA meltblown (Polylactic acid meltblown) which can be widely used for masks, filters, filter elements, etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: Yes, you can send us the details of your wholesale order of PLA fabrics and our specialists will answer your questions regarding your order. Or you can send 3rd party to our company for inspection for your cargo in case you can not come China during the Covid.

Q: What is the shipping method?

A: Basically, we offer door to door service to our wholesale clients. We have also EXW, FOB and CIF conditions for our wholesale PLA fabrics clients.

The exact method of shipment will depend on the order type and the geographical location of your location.

Q: How about the Payment term?

A: We are trying to offer you competitive price offerings and payment methods. Our typical payment term includes 50% of the price paid in advance by TT, balance after inspection before the delivery.

We accept also T/T, L/C and are ready to discuss other payment options, if necessary.